Modified copper bismuthate photocatalyst and preparation method thereof

A photocatalyst, copper bismuth acid technology, applied in the field of photocatalysis, can solve the problems of high equipment requirements, weakened acidity, harsh reaction conditions, etc., and achieve the effect of good visible light response performance, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A modified copper bismuthate photocatalyst is provided, the modified copper bismuthate photocatalyst is a modified copper bismuthate photocatalyst doped with metal aluminum, and the modified copper bismuthate photocatalyst can be loaded on a cordierite honeycomb on a ceramic sheet.

Embodiment 2

[0025] Provide a kind of preparation method of modified copper bismuth acid photocatalyst, comprising the steps of:

[0026] (1) According to the volume ratio of 3:2:1:1, take 60ml of acetone, 40ml of glycerol, 20ml of nitric acid and 20ml of anhydrous acetic acid, stir evenly to obtain a clear and transparent solution;

[0027] (2) According to stoichiometry, that is, the ratio of substances is 1:1.9:0.1, 4.832g of copper nitrate trihydrate, 18.918g of bismuth nitrate pentahydrate and 0.375g of aluminum nitrate nonahydrate were added to the clear and transparent solution. Stir until a pale yellow gel is formed;

[0028] (3) Take out the yellow gel and place it in an oven at 140°C for half an hour to obtain a dried gel;

[0029] (4) The dried gel obtained in step (3) was placed in a muffle furnace and calcined at 500° C. for 3 hours to obtain a modified copper bismuthate photocatalyst sample.

[0030] Provide a kind of modified bismuth acid copper photocatalyst-supported hon...

Embodiment 3

[0037] (1) Characterization of modified copper bismuthate photocatalyst

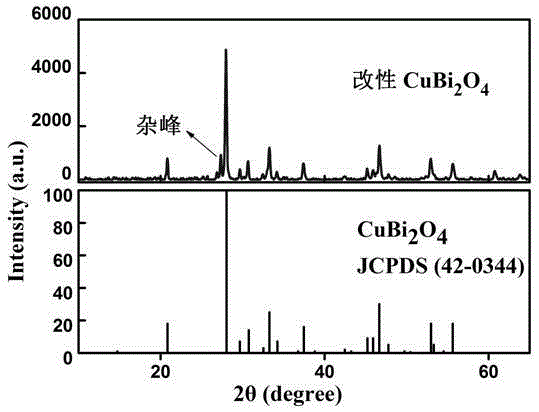

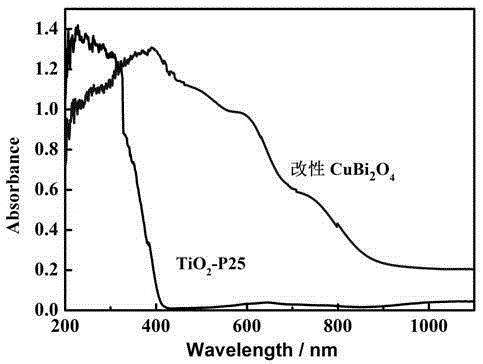

[0038] see figure 1 , the diffraction peaks of the modified copper bismuthate photocatalyst sample prepared at 500 °C are basically the same as the standard characteristic diffraction peaks of copper bismuthate, indicating that the modified copper bismuthate photocatalyst material prepared by this method has a crystal structure of spinel ; There are miscellaneous peaks near the main peak, indicating that aluminum ions have been doped into the copper bismuth acid photocatalyst. see figure 2 , the modified copper bismuthate photocatalyst sample has good light absorption ability in the near ultraviolet and visible light regions, which is much higher than the common titanium dioxide P25 photocatalytic material, and the improved copper bismuthate photocatalyst has obvious ion resonance phenomenon near 400nm , is due to the introduction of impurity element aluminum.

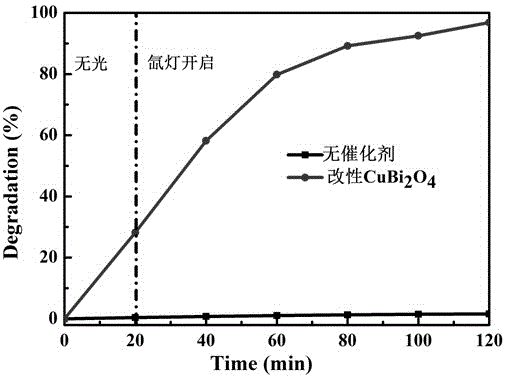

[0039] (2) Photocatalytic activity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com