Preparation method of color-tunable titanium dioxide with high photocatalytic activity

A technology of photocatalytic activity and titanium dioxide, which is applied in the fields of chemistry and material science, can solve the problems of titanium dioxide color unadjustable, low catalytic activity, poor stability, etc., and achieve the effect of convenient large-scale production, high photocatalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of titanium dioxide with adjustable color and high-efficiency photocatalytic activity uses various crystalline or amorphous titanium dioxide as raw materials, and uses metal hydride as a reducing agent to prepare titanium dioxide with adjustable color and high-efficiency photocatalysis by a low-temperature solid-state reaction method. The titanium dioxide of catalytic activity specifically comprises the following steps:

[0035] (1) mixing and grinding the metal hydride and titanium dioxide evenly to obtain a mixture;

[0036] (2) Under an inert atmosphere, heat the mixture at 200-400°C for 5min-10h. As the reaction temperature increases or the reaction time prolongs, the color of titanium dioxide gradually changes from white to light yellow, light gray, light blue, Blue, dark blue to black, according to the color of the preparation, stop the reaction in time, cool in an inert atmosphere, and get the crude product;

[0037] If the reaction temper...

Embodiment 1

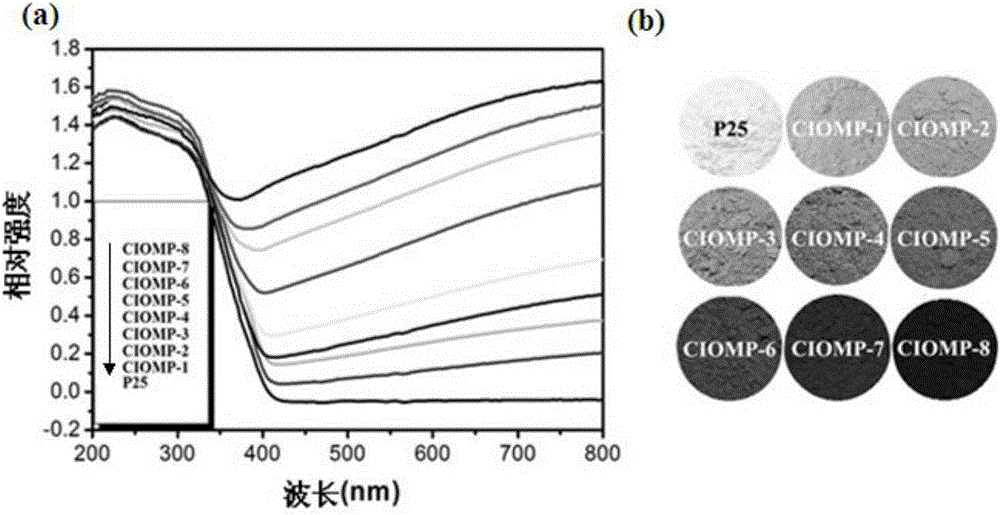

[0044] combine figure 1 , 6 -11 illustrates embodiment 1

[0045] (1) Grinding 1.9g sodium borohydride and 4.0g photocatalyst P25 (metal hydride: P25=1:1) in a mortar to obtain a mixture;

[0046] (2) Put the mixture into a porcelain boat, heat it to 300°C or 350°C at a heating rate of 10°C / min in an atmosphere furnace filled with argon, keep it for 5-120min, and naturally cool to room temperature to obtain the crude product ;

[0047] (3) The crude product obtained after the reaction was washed three times with water and ethanol respectively, and dried in vacuum at 70° C. to obtain titanium dioxide powder, as marked in Table 1.

[0048] figure 1 Among them, (a) is the UV-visible solid diffuse reflectance spectrum of different titanium dioxide powders prepared in Example 1 of the present invention, figure 1 In (a), the curves from top to bottom are CIOMP-8, CIOMP-7, CIOMP-6, CIOMP-5, CIOMP-4, CIOMP-3, CIOMP-2, CIOMP-1 and P25 UV-visible solids Diffuse reflectance spectru...

Embodiment 2

[0059] (1) Grinding 0.38g sodium borohydride and 4.0g photocatalyst P25 (metal hydride: P25=0.2:1) in a mortar evenly to obtain a mixture;

[0060] (2) Put the mixture into a porcelain boat, heat it to 400°C at a heating rate of 10°C / min in an atmosphere furnace filled with argon, keep it for 120min, and naturally cool to room temperature to obtain a crude product;

[0061] (3) The crude product obtained after the reaction was washed three times with water and ethanol respectively, and dried in vacuum at 70° C. to obtain black titanium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com