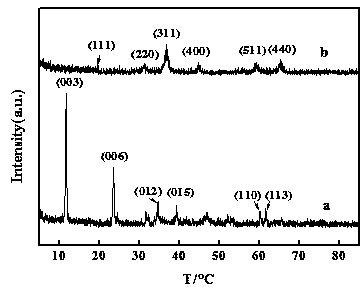

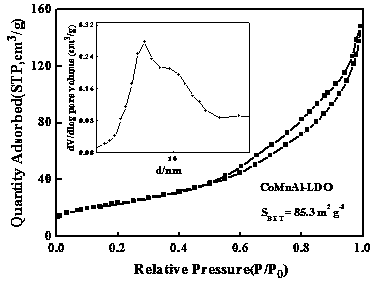

Preparation method and application of low-temperature flue gas denitration catalyst based on CoMnAl layered double hydroxide

A denitration catalyst, low temperature flue gas technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Improve anti-SO2 poisoning ability, improve catalytic performance, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 4.366 g of cobalt nitrate nonahydrate, 1.876 g of aluminum nitrate nonahydrate, measure 1.2 mL of manganese nitrate into a beaker, add 80.0 mL of deionized water into the beaker, and stir with a magnetic stirrer for 10 min to dissolve them completely ,stand-by;

[0044] (2) Weigh 1.875 g of hexamethylenetetramine, and add 183.0 mL of deionized water into the beaker to prepare it to a concentration of 0.10 mol L -1 The hexamethylenetetramine solution, stand-by;

[0045] (3) Add the above-prepared hexamethylenetetramine solution into the above-prepared mixed nitrate solution, stir vigorously at 800r / min for 30 minutes, and then seal the obtained precipitate and mother liquor in polytetrafluoroethylene In an ethylene-lined stainless steel reactor, heat in an oven at 140 °C for 12 h;

[0046] (4) After the reaction kettle is naturally cooled, filter the reacted solution to obtain the precipitate, wash it with deionized water several times until neutral, put it i...

Embodiment 2

[0054] (1) Weigh 2.911 g of cobalt nitrate nonahydrate, 1.876 g of aluminum nitrate nonahydrate, measure 2.4 mL of manganese nitrate into a beaker, add 70.0 mL of deionized water into the beaker, and stir with a magnetic stirrer for 10 min to dissolve them completely ,stand-by;

[0055] (2) Weigh 1.875 g of hexamethylenetetramine, and add 183.0 mL of deionized water into the beaker to prepare it to a concentration of 0.10 mol L -1 The hexamethylenetetramine solution, stand-by;

[0056] (3) Add the above-prepared hexamethylenetetramine solution into the above-prepared mixed nitrate solution, stir vigorously at 800r / min for 30 minutes, and then seal the obtained precipitate and mother liquor in polytetrafluoroethylene In an ethylene-lined stainless steel reactor, heat in an oven at 140 °C for 12 h;

[0057] (4) After the reaction kettle is naturally cooled, filter the reacted solution to obtain the precipitate, wash it with deionized water several times until neutral, put it i...

Embodiment 3

[0061] (1) Weigh 1.455 g of cobalt nitrate nonahydrate, 1.876 g of aluminum nitrate nonahydrate, measure 3.6 mL of manganese nitrate into a beaker, add 63.0 mL of deionized water into the beaker, and stir with a magnetic stirrer for 10 min to dissolve them completely ,stand-by;

[0062] (2) Weigh 1.875 g of hexamethylenetetramine, and add 183.0 mL of deionized water into the beaker to prepare it to a concentration of 0.10 mol L -1 The hexamethylenetetramine solution, stand-by;

[0063] (3) Add the above-prepared hexamethylenetetramine solution into the above-prepared mixed nitrate solution, stir vigorously at 800r / min for 30 minutes, and then seal the obtained precipitate and mother liquor in polytetrafluoroethylene In an ethylene-lined stainless steel reactor, heat in an oven at 140 °C for 12 h;

[0064] (4) After the reaction kettle was naturally cooled, the reacted solution was suction-filtered to obtain a precipitate, which was washed with deionized water several times u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com