Aluminum oxide coated nano flaky hexagonal boron nitride composite powder as well as preparation method and application thereof

A technology of hexagonal boron nitride and nano flakes, which is applied in the field of preparation of alumina-coated nano flake hexagonal boron nitride composite powder, which can solve the problems of inability to observe the reaction process intuitively, high equipment requirements, and technical difficulties. problems, to achieve the effect of improving mechanical properties and friction and wear properties, low equipment requirements, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

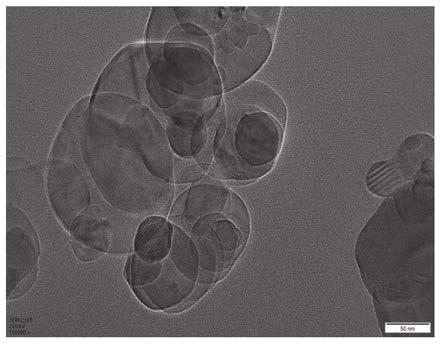

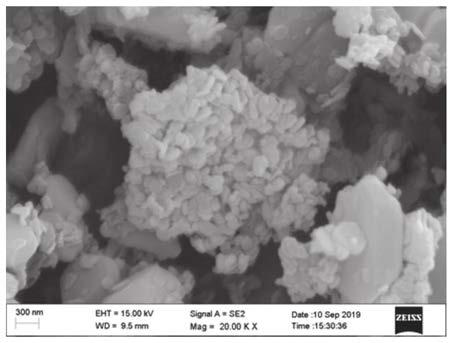

[0041] (1) Weigh 0.2g of h-BN powder with a particle size of 100nm, pickle in HF solution for 20min, centrifuge at 4000r / min for 5min, and then wash with absolute ethanol. The powder after pickling was dispersed in 100mL of absolute ethanol, an appropriate amount of dispersant PVP was added, ultrasonically dispersed for 30min, and then 50mL of distilled water was added to continue ultrasonically stirring for 10min.

[0042] (2) Add 30g / L aluminum nitrate solution (Al(NO 3 ) 3 9H 2 O), ultrasonically stirred for 10min. The obtained mixed solution was placed in a magnetic stirrer, heated and stirred in a water bath, and the temperature was kept at 75°C. At the same time, sodium acetate buffer solution of acetic acid was added to control the pH value to 4.5.

[0043] (3) Slowly add dilute ammonia water to the above mixed solution to adjust the pH to 7.5 at a rate of 0.15 mL / min. After the dropwise addition was completed, the mixture was incubated for 30 minutes, and then all...

Embodiment 3

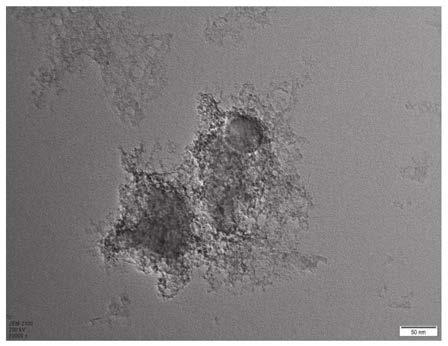

[0051] (1) Weigh 0.05g of h-BN powder with a particle size of 100nm, pickle it in HF solution for 20min, centrifuge it at 5000r / min for 5min, and wash it with absolute ethanol. The powder after pickling was dispersed in 100mL of absolute ethanol, an appropriate amount of dispersant PVP was added, ultrasonically dispersed for 20min, and then 50mL of distilled water was added to continue ultrasonically stirring for 20min.

[0052] (2) Add 7.5g / L aluminum nitrate solution (Al(NO 3 ) 3 9H 2 O), ultrasonically stirred for 30min. The obtained mixed solution was placed in a magnetic stirrer, heated and stirred in a water bath, and the temperature was kept at 60°C. At the same time, acetic acid sodium acetate buffer solution was added to control the pH value to 6.

[0053] (3) Slowly add dilute ammonia water to the above mixed solution to adjust the pH to 8.5 at a rate of 0.15 mL / min. After the dropwise addition was completed, it was incubated for 30 minutes, and then allowed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com