Preparation method of calcined magnesium-aluminum hydrotalcite film

A magnesium-aluminum hydrotalcite and film technology, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of low adsorption capacity, harsh conditions, difficult control, etc., and achieve easy preparation process and acid resistance Good performance and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

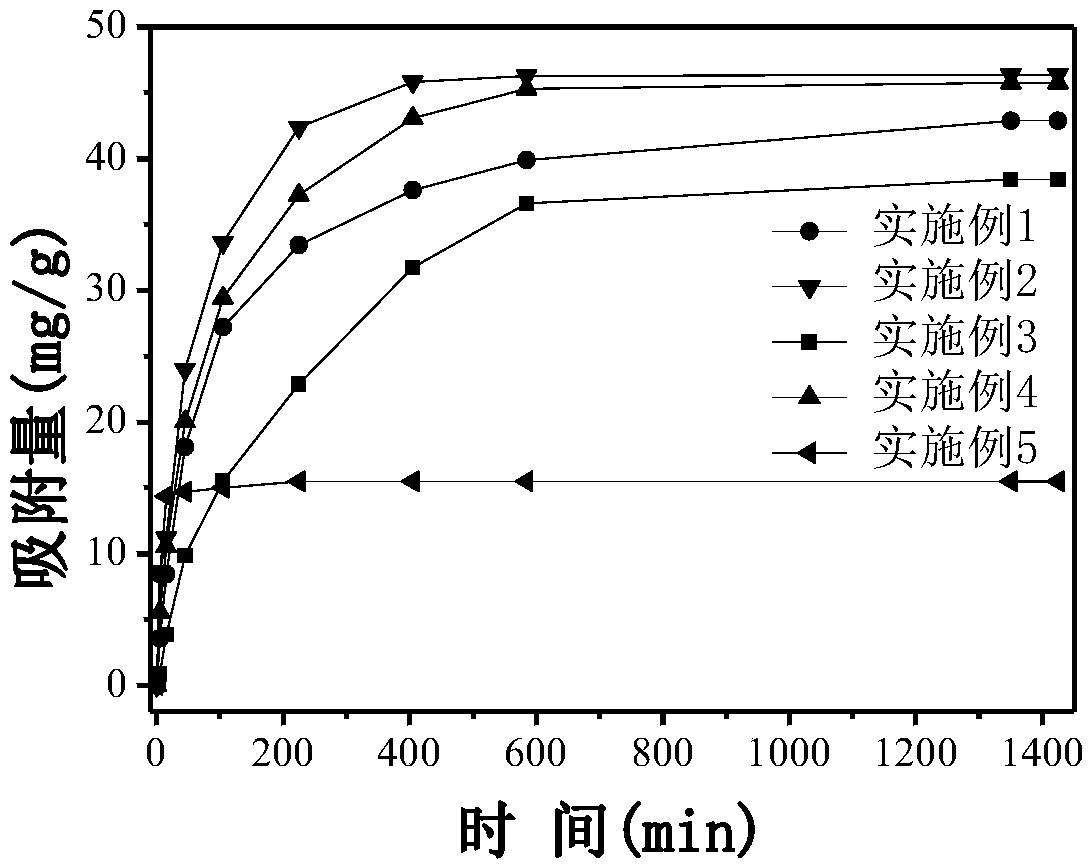

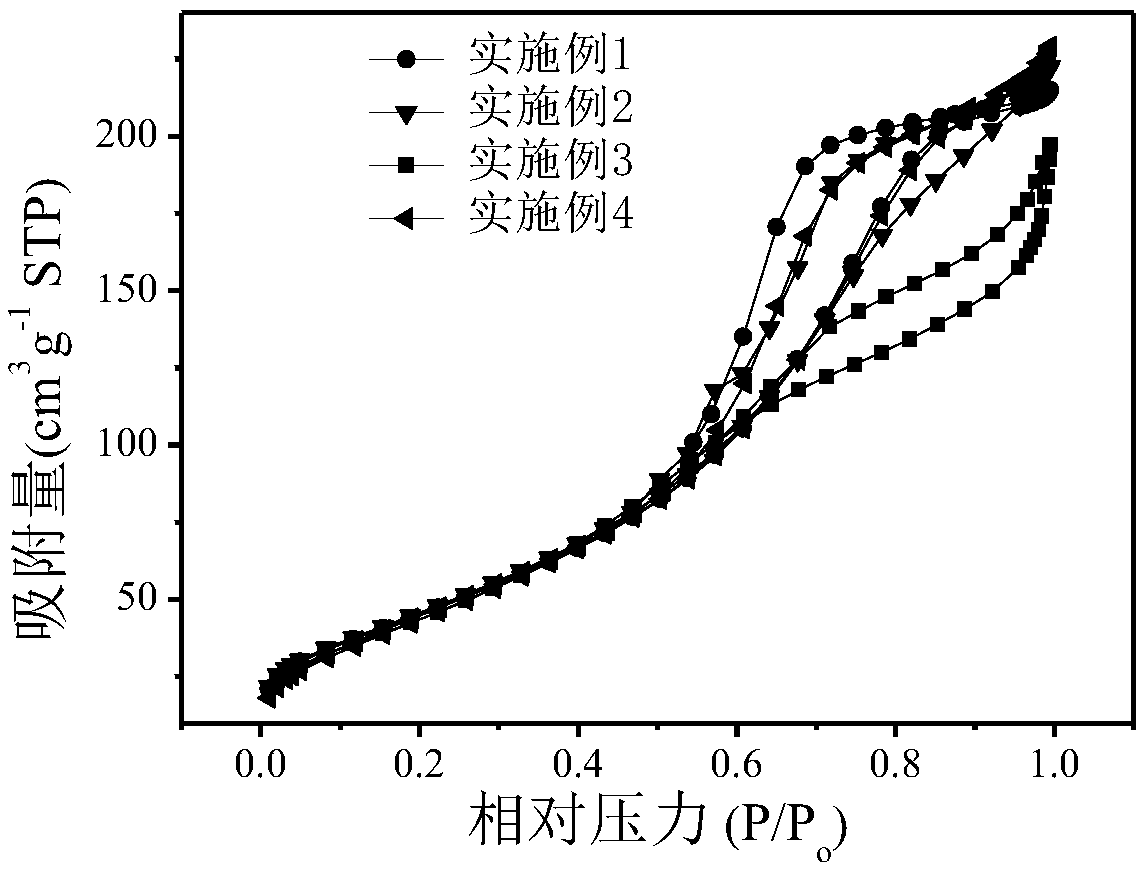

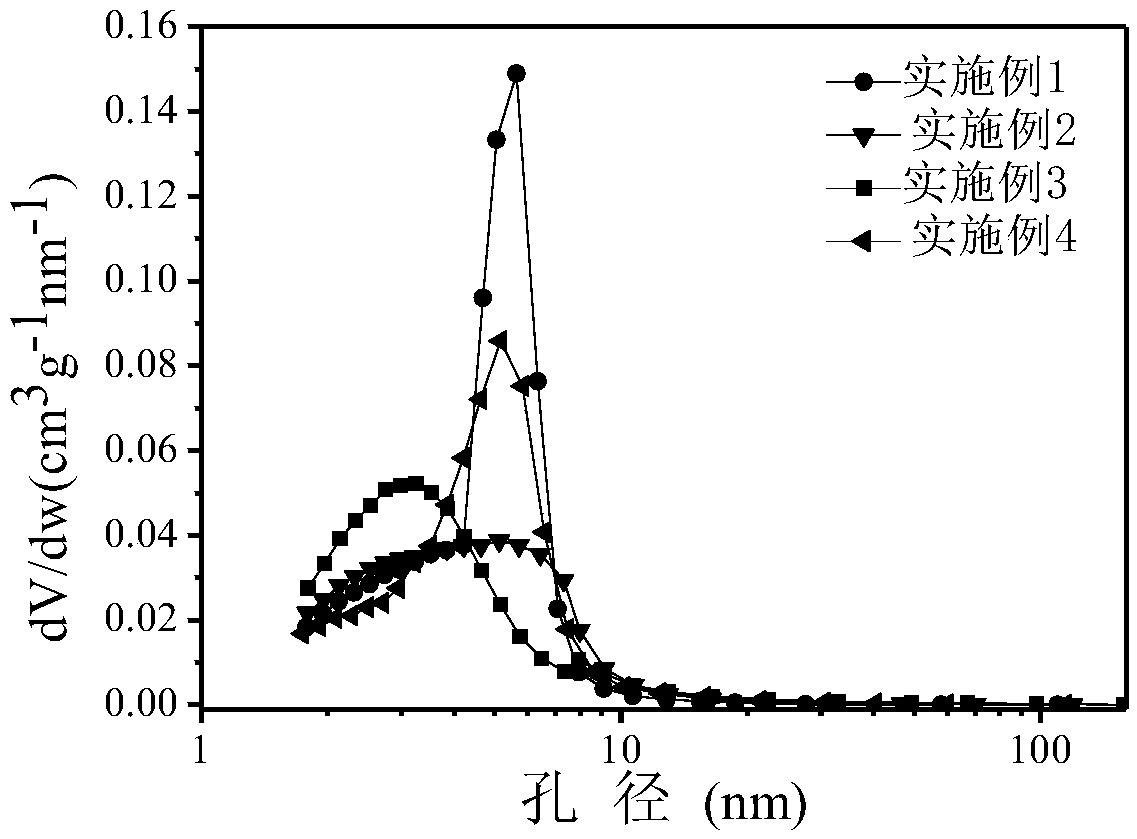

[0031] Disperse 6.00 g of aluminum nitrate nonahydrate and 12.31 g of magnesium nitrate hexahydrate in 50 mL of deionized water at room temperature to form a mixed solution; then slowly add 20 mL of concentrated ammonia water with a volume fraction of 20%, centrifuge the obtained precipitate and use Wash with deionized water to pH ≈ 7.5; disperse the washed precipitate in 50 mL of deionized water, stir at a rate of 400 r / min at room temperature, then add 5 g of citric acid monohydrate and 5 g of 10% PVA solution at room temperature Stirring was continued for 12 hours to obtain magnesium aluminum hydrotalcite sol; the product was tape-cast on a polytetrafluoroethylene sheet (6cm×8cm), and the film was peeled off after natural drying at room temperature for 48 hours; then, it was placed in a muffle furnace at 3°C The temperature was raised to 500°C at a heating rate of / min, and after 4 hours of calcination, the calcined magnesium aluminum hydrotalcite film was obtained. The XRD...

Embodiment 2

[0034] Disperse 6.00g of aluminum nitrate nonahydrate and 8.21g of magnesium nitrate hexahydrate in 50mL of deionized water at room temperature to form a mixed solution; then, slowly add 20mL of concentrated ammonia water with a volume fraction of 20%, and centrifuge the obtained precipitate And wash with deionized water to pH ≈ 7.5; disperse the washed precipitate in 50mL of deionized water, stir at a rate of 400r / min at room temperature, then add 4g of citric acid monohydrate and 5g of PVA with a mass fraction of 10% in sequence Solution, continue to stir at room temperature for 12 hours to obtain magnesium aluminum hydrotalcite sol; cast the product on a polytetrafluoroethylene sheet (6cm×8cm), and peel off the film after natural drying at room temperature for 48 hours; then, put it in a muffle furnace The temperature was raised to 400° C. at a heating rate of 3° C. / min, and calcined for 4 hours to obtain a calcined magnesium aluminum hydrotalcite film. The XRD detection of...

Embodiment 3

[0037] Disperse 6.00g of aluminum nitrate nonahydrate and 24.01g of magnesium nitrate hexahydrate in 50mL of deionized water at room temperature to form a mixed solution; then slowly add 20mL of concentrated ammonia water with a volume fraction of 20%, centrifuge the obtained precipitate and use Wash with deionized water to pH ≈ 7.5; disperse the washed precipitate in 50mL of deionized water, stir at a rate of 400r / min at room temperature, then add 6g of citric acid monohydrate and 5g of 10% PVA solution in sequence , continue stirring at room temperature for 12 hours to obtain magnesium aluminum hydrotalcite sol; cast the product on a polytetrafluoroethylene sheet (6cm×8cm), and peel off the film after natural drying at room temperature for 48 hours; then put the film in a muffle furnace The temperature was raised to 500° C. at a heating rate of 3° C. / min, and calcined for 4 hours to obtain a calcined magnesium aluminum hydrotalcite film. The XRD detection of the unbaked samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com