Glucose sensor electrode without enzyme with nickel-aluminium-hydrotalcite nano-chip arrays on substrate of titanium

A glucose sensor and nanosheet array technology, applied in the field of enzyme-free glucose sensor electrodes, can solve the problems of difficult storage, poor electrochemical performance, and expensive glucose oxidase, and achieve the effect of easy storage and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

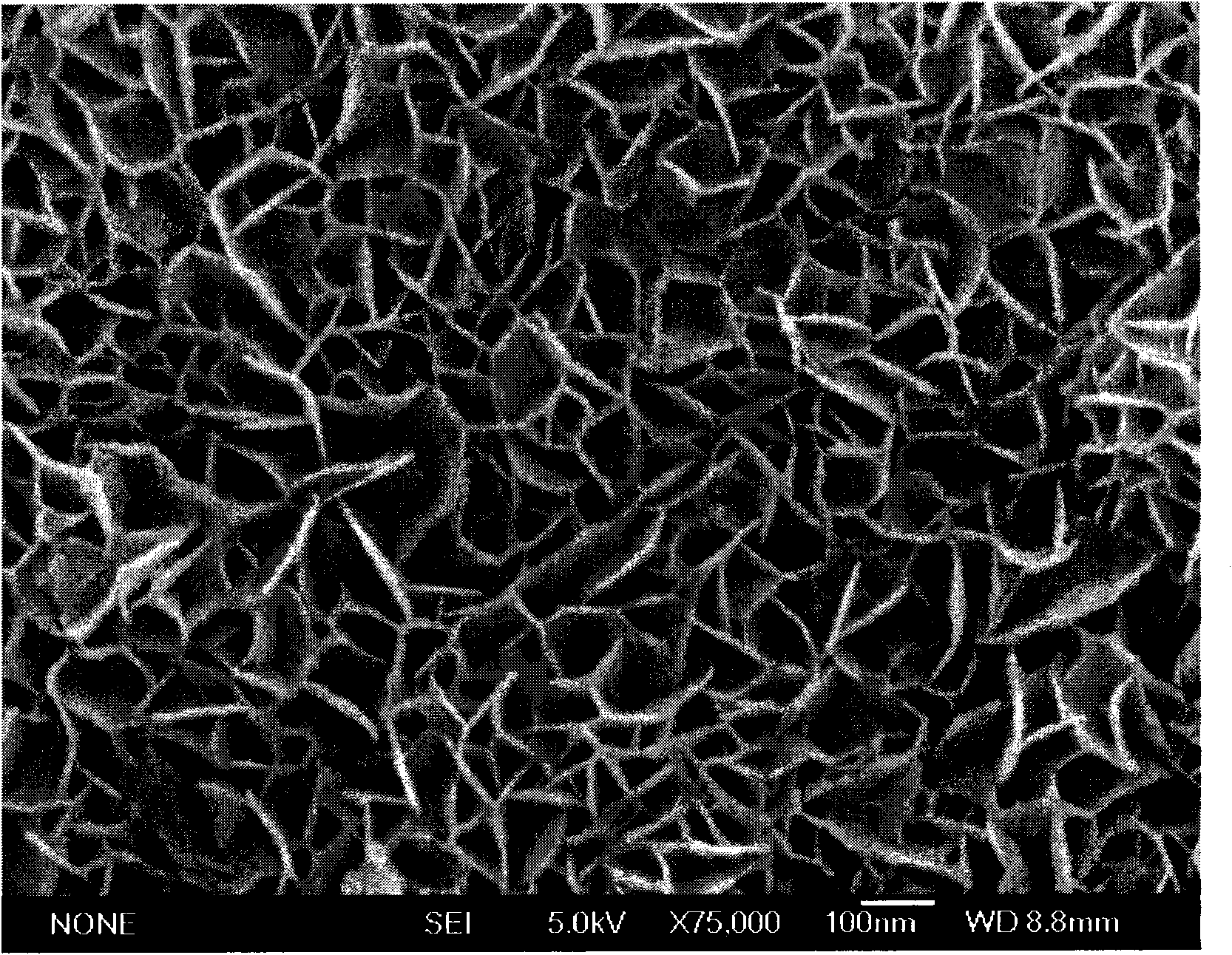

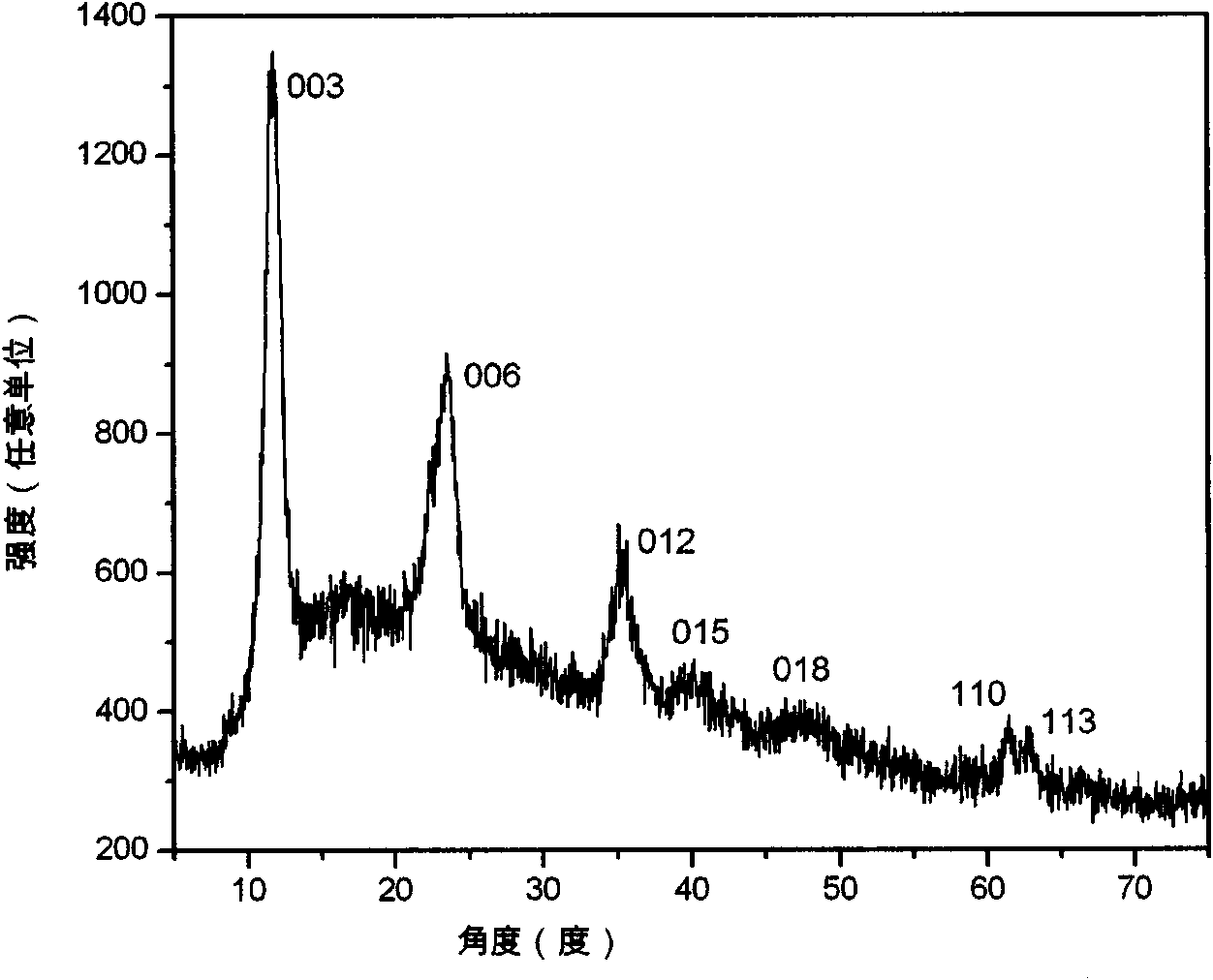

[0027] Nickel-aluminum hydrotalcite nanosheet array electrode preparation: 2.036 grams of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 1.313 grams of aluminum nitrate nonahydrate (Al(NO 3 ) 3 .9H 2 O), 4.200 grams of urea (CON 2 h 4 ) was dissolved in 70.0 ml of water, stirred with a magnetic stirrer to fully dissolve, mixed evenly, and made into a mixed solution; a titanium metal sheet with a thickness of 0.2 mm, a width of 2.0 mm, and a length of 60.0 mm was washed with dilute hydrofluoric acid (HF) After soaking in the solution and rinsing with clean water, put it into the prepared solution; then place the solution together with the titanium metal in the polytetrafluoroethylene liner in the autoclave and heat it to 95°C for 36 hours; after natural cooling, place the The titanium metal sheet is taken out to obtain an enzyme-free glucose sensor electrode sample of the nickel-aluminum hydrotalcite nanosheet array on the titanium substrate. The samples were subjecte...

Embodiment 2

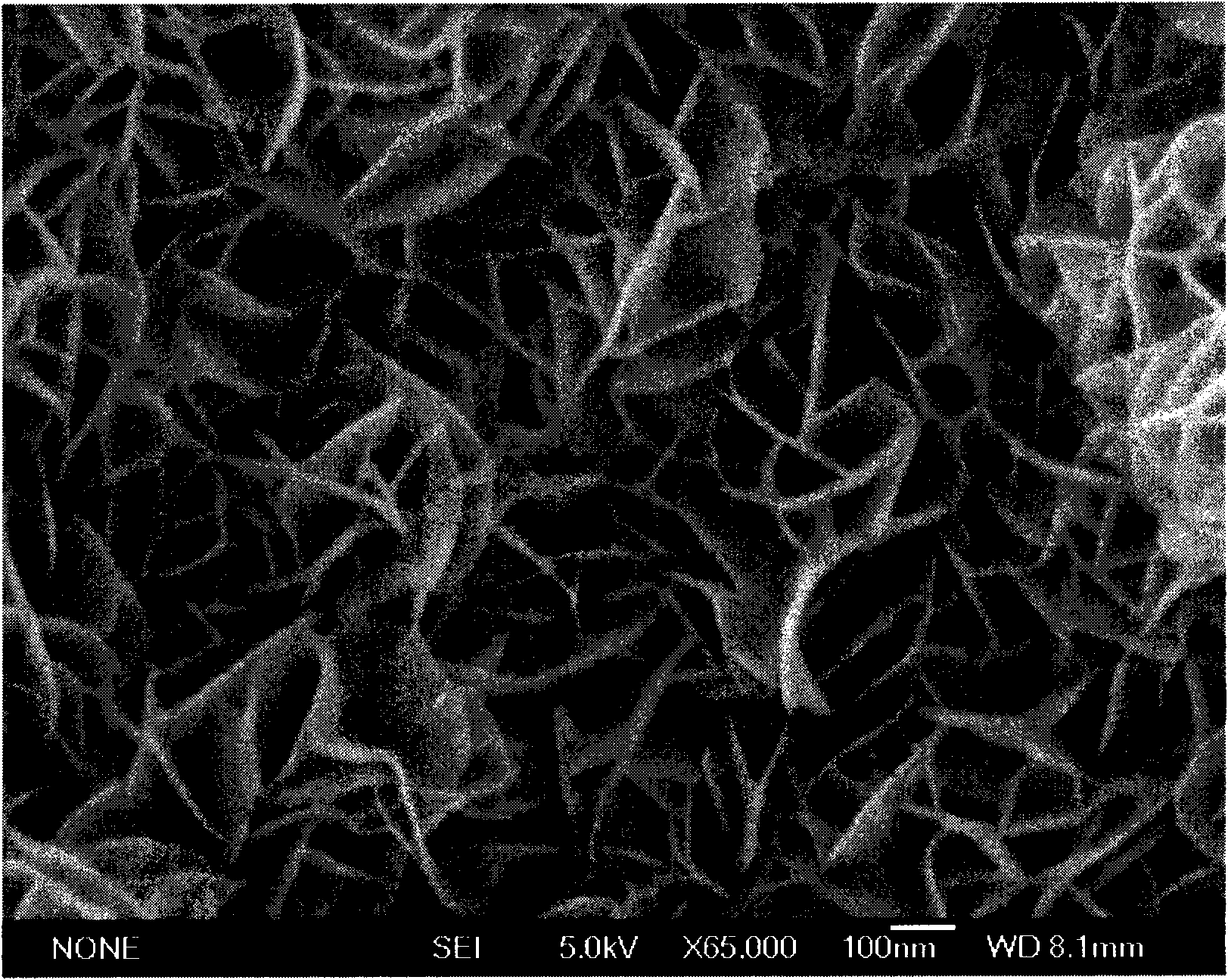

[0029] Nickel-aluminum hydrotalcite nanosheet array electrode preparation: 2.036 grams of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 1.313 grams of aluminum nitrate nonahydrate (Al(NO 3 ) 3 .9H 2 O), 4.200 grams of urea (CON 2 h 4) was dissolved in 140 ml of water, stirred with a magnetic stirrer to fully dissolve, mixed evenly, and made into a mixed solution; a titanium metal sheet with a thickness of 0.2 mm, a width of 2.0 mm, and a length of 60.0 mm was washed with dilute hydrofluoric acid (HF) After soaking in the solution and rinsing with clean water, put it into the prepared solution; then put the aqueous solution together with the titanium metal in the polytetrafluoroethylene liner in the autoclave and heat it to 95°C for 72 hours; after natural cooling, place the The titanium metal sheet is taken out to obtain an enzyme-free glucose sensor electrode sample of the nickel-aluminum hydrotalcite nanosheet array on the titanium substrate. The samples were subj...

Embodiment 3

[0031] Nickel-aluminum hydrotalcite nanosheet array electrode preparation: 2.036 grams of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 1.313 grams of aluminum nitrate nonahydrate (Al(NO 3 ) 3 .9H 2 O), 4.200 grams of urea (CON 2 h 4 ) was dissolved in 70.0 ml of water, stirred with a magnetic stirrer to fully dissolve, mixed evenly, and made into a mixed solution; a titanium metal sheet with a thickness of 0.2 mm, a width of 2.0 mm, and a length of 60.0 mm was washed with dilute hydrofluoric acid (HF) After soaking in the solution and rinsing with clean water, put it into the prepared solution; then put the aqueous solution together with the titanium metal in the polytetrafluoroethylene liner in the autoclave and heat it to 75°C for 72 hours; after natural cooling, place the The titanium metal sheet is taken out to obtain an enzyme-free glucose sensor electrode sample of the nickel-aluminum hydrotalcite nanosheet array on the titanium substrate. The samples were su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com