Europium and manganese codoped and activated blue-green fluorescent powder and preparation method thereof

A fluorescent powder, blue-green technology, applied in the field of blue-green fluorescent powder and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] 2. A blue-green fluorescent powder preparation method activated by co-doping of europium and manganese, characterized in that it comprises the following steps:

[0019] ①According to the general chemical formula Ba 1-x Sr 1-y al 10 o 17 :xEu 2+ ,yMn 2+ Calculate separately, weigh the reagent (barium carbonate BaCO 3 (A.R.) (A.R. means analytical grade), strontium oxide SrO (A.R.), aluminum nitrate nonahydrate Al (NO 3 ) 3 9H 2 O (99.99%), manganese carbonate MnCO 3 (A.R.) and europium oxide Eu 2 o 3 (purity 99.99%) fully mix these components;

[0020] ②Sinter the above mixture in a high-temperature furnace, the atmosphere is hydrogen, the sintering temperature is 1000-1400°C, and the sintering time is 3-8 hours;

[0021] ③ Grinding the above-mentioned sintered material, grinding and sieving, the fineness is 200-400 mesh;

[0022] ④ Wash and filter with deionized water at 50-100°C, and dry at 100-150°C to obtain the desired product.

[0023] 3. A method for...

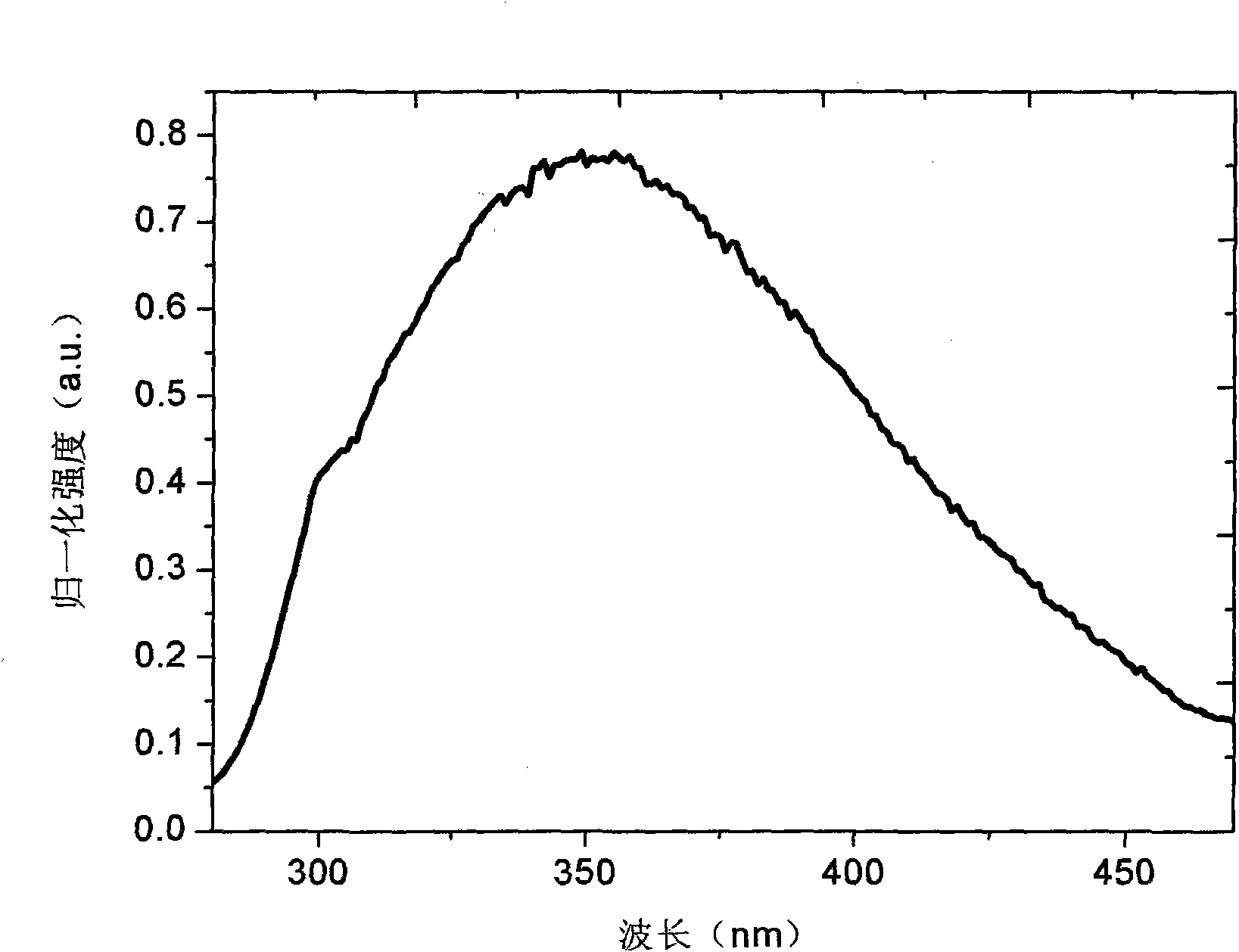

Embodiment 1

[0026] Implementation example 1: the chemical formula is: Ba 0.92 Sr 0.96 al 10 o 17 :0.08Eu 2+ , 0.04Mn 2+ ;

[0027] Preparation method: according to the chemical formula Ba 0.92 Sr 0.96 al 10 o 17 :0.08Eu 2+ , 0.04Mn 2+ Weigh barium carbonate BaCO 3 (A.R.) (A.R. means analytical grade), strontium oxide SrO (A.R.), aluminum nitrate nonahydrate Al (NO 3 ) 3 9H 2 O (99.99%), manganese carbonate MnCO 3 (A.R.) and europium oxide Eu 2 o 3 (purity 99.99%); they were mixed in a mortar with 5% NH 4 Cl flux was mixed, and a small amount of absolute ethanol was added to mix and grind for 2 hours to make it fully mixed; the above mixture was dried and put into a corundum crucible, compacted, and placed in a high-temperature box furnace at a temperature of 100°C / hour. The temperature was ramped up to 1300°C and held for 5 hours. After cooling, take it out and crush, grind, and sieve to a fineness of 400 mesh. Then wash and filter several times with deionized water at...

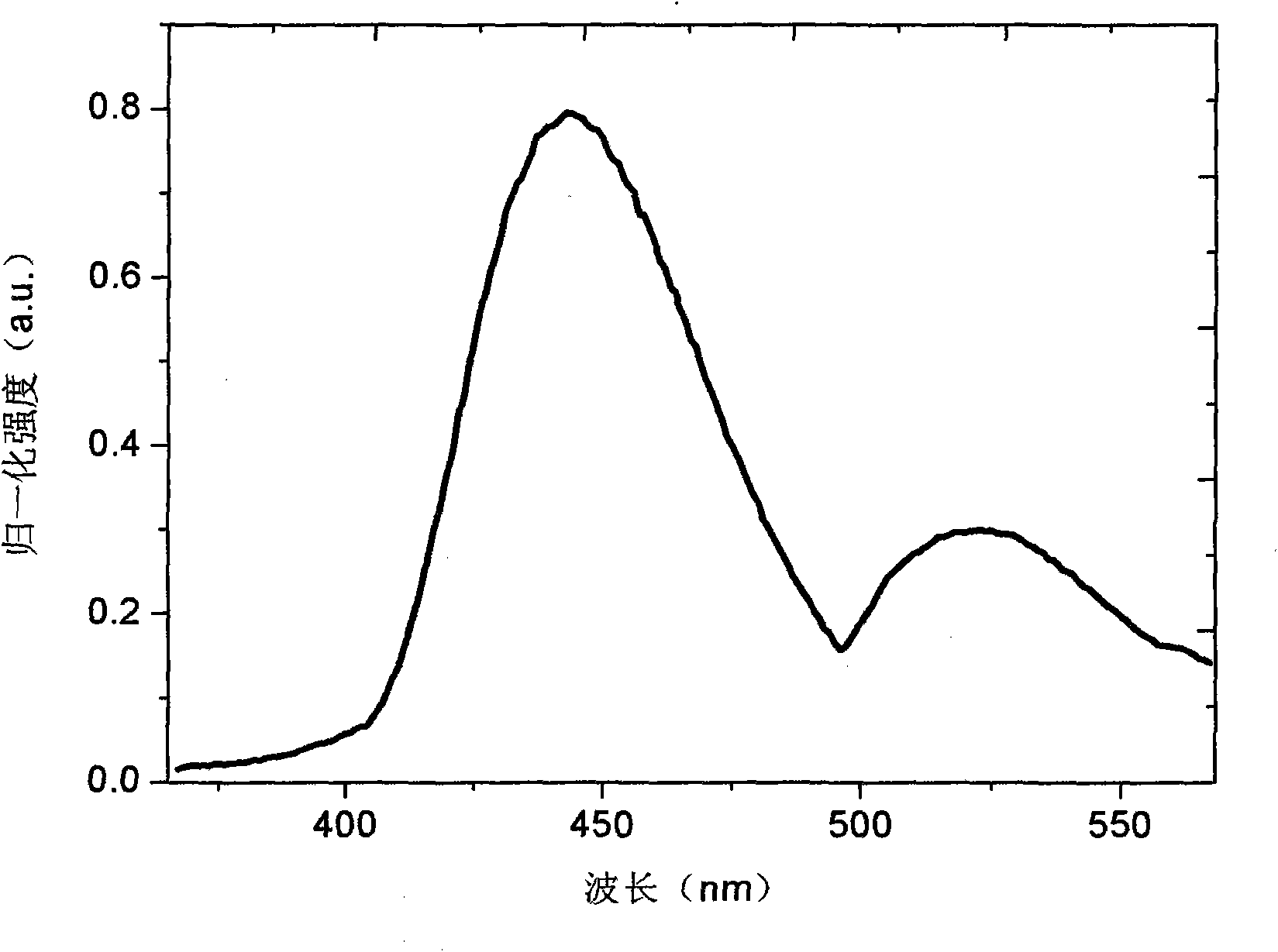

Embodiment 2

[0029] Implementation example 2: the chemical formula is: Ba 0.92 Sr 0.98 al 10 o 17:0.08Eu 2+ , 0.02Mn 2+ ;

[0030] Preparation method: according to the chemical formula Ba 0.92 Sr 0.98 al 10 o 17 :0.08Eu 2+ , 0.02Mn 2+ Weigh barium carbonate BaCO 3 (A.R.) (A.R. means analytical grade), strontium oxide SrO (A.R.), aluminum nitrate nonahydrate Al (NO 3 ) 3 9H 2 O (99.99%), manganese carbonate MnCO 3 (A.R.) and europium oxide Eu 2 o 3 (purity 99.99%); they were mixed with a small amount of absolute ethanol in a mortar and ground for 2 hours to make them fully mixed; the above mixture was dried and packed into a corundum crucible, compacted, placed in a high-temperature box furnace, The temperature was raised to 1350°C at a rate of 100°C / hour and maintained for 4 hours. After cooling, take it out and crush, grind, and sieve to a fineness of 400 mesh. Then wash and filter several times with deionized water at about 80°C, bake in an oven at 120°C for 5 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com