Method for preparing ultrathin g-C3N4/Al2O3 nano-grade composite photocatalyst

A nanocomposite and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of complex preparation process, long time-consuming, low photocatalytic hydrogen production efficiency, etc., and achieve the effect of simple preparation process, short time-consuming, and improved photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Measure 50 mL of methanol into a round-bottomed flask, weigh 2.5 g of melamine into the above-mentioned round-bottomed flask, and stir for 0.5 h under reflux at 60°C to obtain a suspension.

[0026] (2) Measure 50mL methanol into a beaker, weigh 1.0gAl(NO 3 ) 3 9H 2 O was added to the above beaker, stirred to obtain a clear solution; the solution was transferred to the round bottom flask in step (1), and stirred at 60°C under reflux for 2 hours to obtain a suspension;

[0027] (3) The suspension obtained in step (2) was filtered, washed, and dried; the dried solid was calcined in a muffle furnace at 550°C for 3 hours to obtain Al 2 o 3 / g -C 3 N 4 Composite photocatalyst finished product.

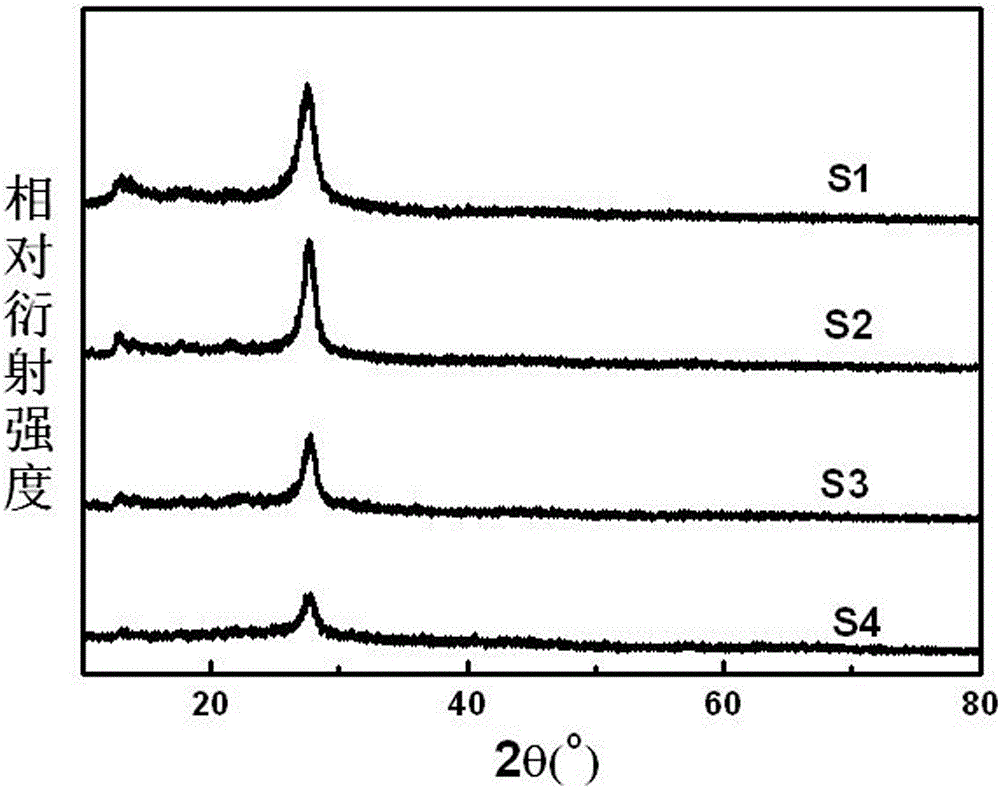

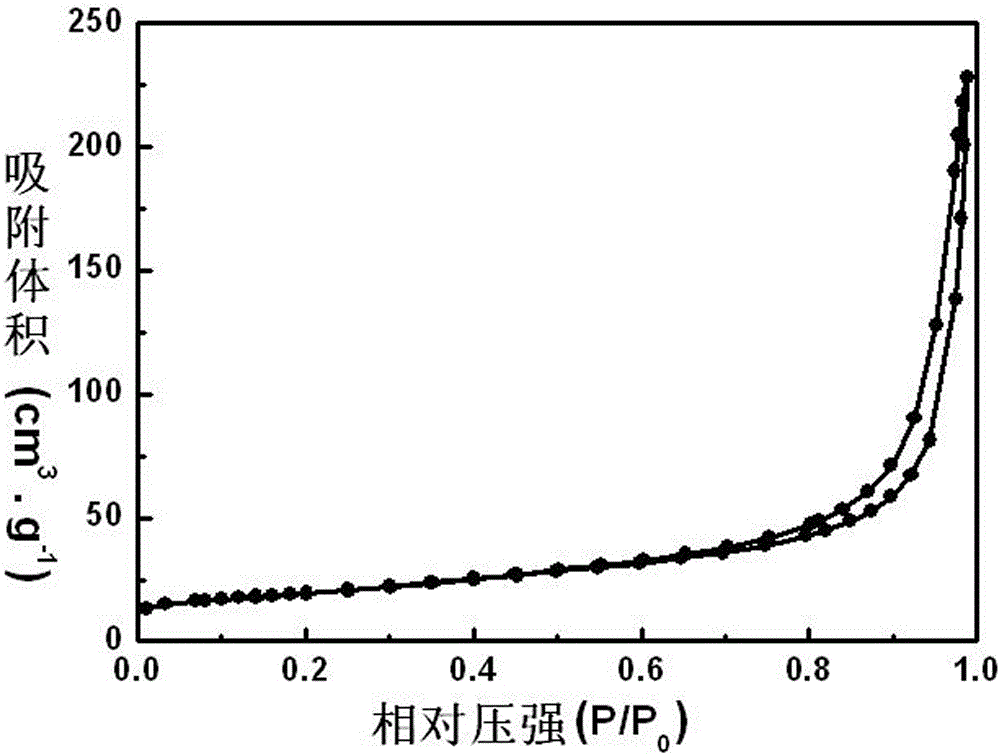

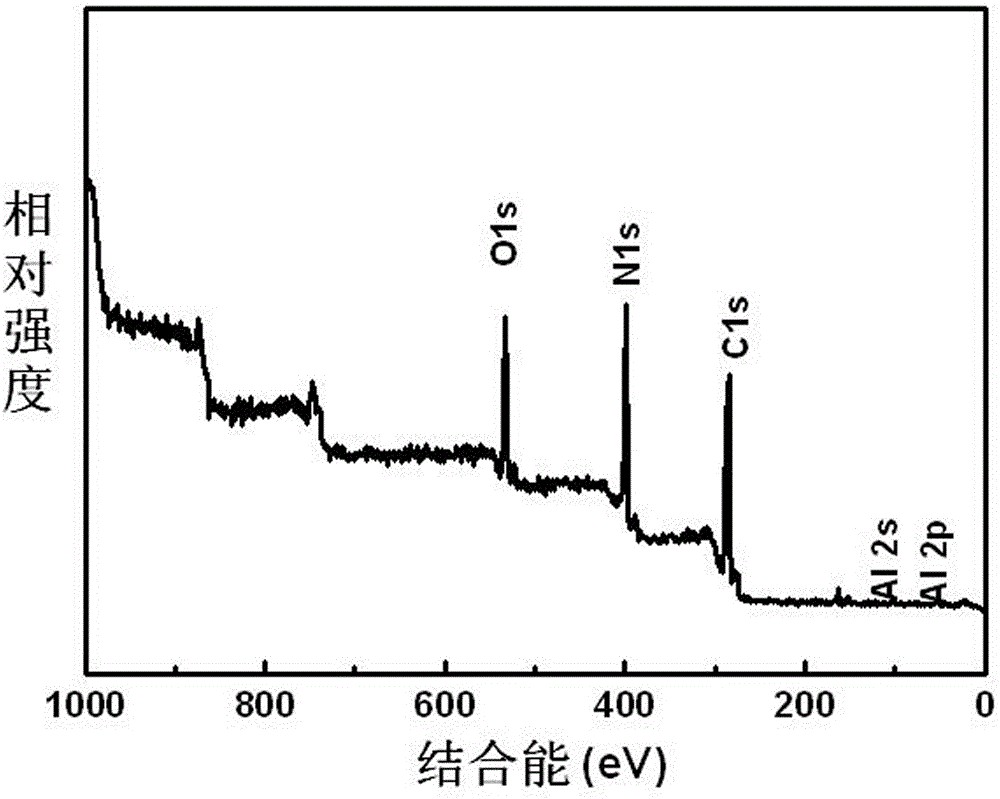

[0028] Gained catalyst is carried out X-ray diffraction test (see figure 1 ), it can be seen that the composite catalyst contains graphite phase C 3 N 4 and amorphous Al 2 o 3 . figure 2 For the Al prepared in Example 1 2 o 3 / g -C 3 N 4 Nitrogen adsorption-desor...

Embodiment 2

[0030] (1) Measure 50 mL of methanol into a round-bottomed flask, weigh 2.5 g of melamine into the above-mentioned round-bottomed flask, and stir for 0.5 h under reflux at 60°C to obtain a suspension.

[0031] (2) Measure 50mL methanol into a beaker, weigh 2.0 gAl(NO 3 ) 3 9H 2 O was added to the above beaker, and stirred to obtain a clear solution; the solution was transferred to the round bottom flask in step (1), and stirred at 60°C under reflux for 1.5 hours to obtain a suspension;

[0032] (3) Other preparation methods are the same as in Example 1.

[0033] For the resulting finished product Al 2 o 3 / g -C 3 N 4 Composite photocatalysts were tested by X-ray diffraction (see figure 1 ), it can be seen that the composite catalyst contains graphite phase C 3 N 4 , and the amorphous Al 2 o 3 ; The specific surface area of the composite catalyst is 72.6 m 2 / g; Carry out visible light catalytic water splitting experiment according to the method for embodiment 1, ...

Embodiment 3

[0035] (1) Measure 50 mL of methanol into a round-bottomed flask, weigh 2.5 g of melamine into the above-mentioned round-bottomed flask, and stir for 0.5 h under reflux at 60°C to obtain a suspension.

[0036] (2) Measure 50mL methanol into a beaker, weigh 0.5gAl(NO 3 ) 3 9H 2 O was added to the above beaker, stirred to obtain a clear solution; the solution was transferred to the round bottom flask in step (1), and stirred at 60°C under reflux for 2 hours to obtain a suspension;

[0037] (3) Other preparation methods are the same as in Example 1.

[0038] For the resulting finished product Al 2 o 3 / g -C 3 N 4 Composite photocatalysts were tested by X-ray diffraction (see figure 1 ), it can be seen that the composite catalyst contains graphite phase C 3 N 4 , and the amorphous Al 2 o 3 ; The specific surface area of the composite catalyst is 32.1 m 2 / g; Carry out visible light catalytic water splitting experiment according to the method for embodiment 1, see F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com