Preparation method of amino acid ion intercalated ZnAl-LDHs film

A technology of amino acid and znal-ldhs, which is applied in coating, metal material coating process, etc., can solve the problems of poor environmental performance of inorganic ion corrosion inhibitors, non-environmental protection of inorganic ion corrosion inhibitors, and easy pollution of the environment, so as to prevent Further corrosion, improved corrosion resistance, simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

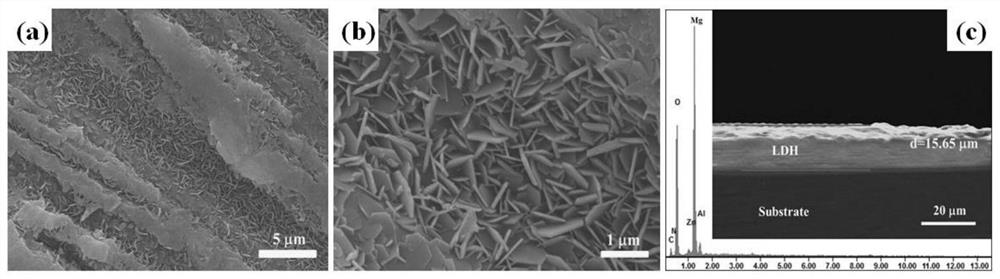

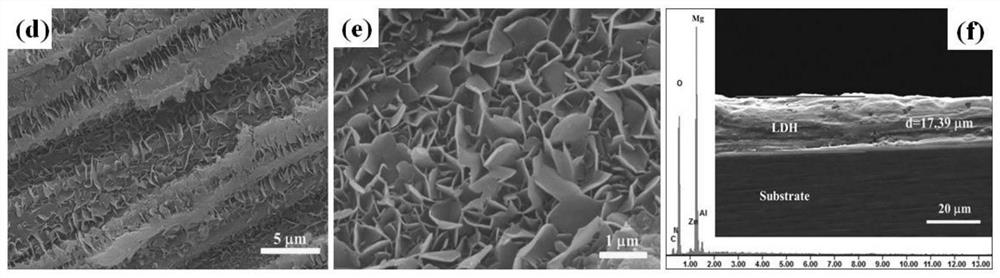

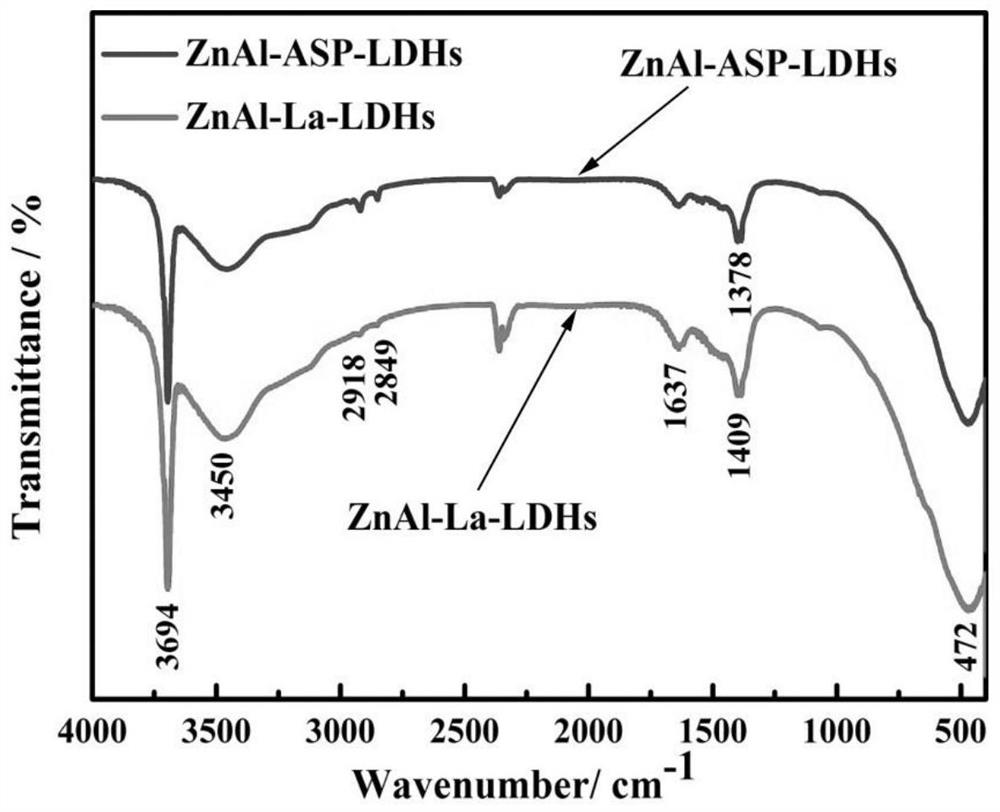

Embodiment 1

[0032]A method for preparing amino acid ion intercalation ZnAl-LDHs film, which is characterized in that it comprises the following steps:

[0033]Step S001, pretreating the surface of the magnesium alloy, specifically including the following steps: Step S0011, selecting the required size of magnesium alloy and using sandpaper to polish; the selected magnesium alloy is AZ31 magnesium alloy, and the cutting size is 20mm× 25mm×2.0mm, then use 400, 800, 1200, 2000 mesh SiC sandpaper for polishing. Step S0012, placing the polished magnesium alloy in an ethanol solution for ultrasonic cleaning for 15 minutes, and performing a cold air drying process. In step S0013, the magnesium alloy obtained in step S0012 is placed in a 2 mol / L sodium hydroxide solution for ultrasonic cleaning. In step S0014, the magnesium alloy obtained in step S0013 is placed in an ethanol solution for ultrasonic cleaning for 10 minutes, and placed in an oven for drying, and the drying temperature is 60°C. Using this st...

Embodiment 2

[0040]The difference between this embodiment and the first embodiment is that in the step S003, 0.444 g of 0.04 mol / L sodium laurate is specifically added dropwise to the mixed solution. In step S004, a 2mol / L sodium hydroxide solution is added to the solution obtained in step S003, and the pH of the solution is adjusted to 10. In step S005, the magnesium alloy obtained by pretreatment in step S001 and the solution obtained in step S004 are placed in a polytetrafluoroethylene autoclave for heating treatment; wherein the heating temperature of the polytetrafluoroethylene autoclave is 393K and the heating time is 12 hours. In step S006, the magnesium alloy treated in step S005 is cleaned with deionized water and placed in a vacuum for drying at a drying temperature of 60° C. and a drying time of 12 hours to obtain a ZnAl-La-LDHs film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com