Preparation method of sol solution containing two-dimensional nano container supported corrosion inhibitor

A technology of nano-containers and corrosion inhibitors, applied in chemical instruments and methods, zinc compounds, inorganic chemistry, etc., can solve problems affecting the stability of composite sol solutions, reduce the amount of corrosion inhibitors added, and promote the corrosion of metal substrates, etc., to achieve Inhibit agglomeration, increase the concentration, and enhance the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

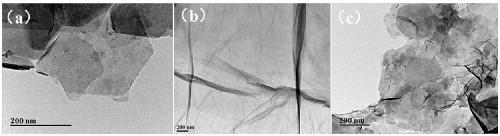

Image

Examples

Embodiment 1

[0020] (1) Disperse 0.2g of graphene oxide in 150mL of aqueous solution. After uniformly dispersed by ultrasonic, add 0.1M zinc nitrate hexahydrate and 0.05M aluminum nitrate nonahydrate in sequence. After mixing evenly, slowly add 0.4M sodium nitrate dropwise And 0.2M sodium hydroxide mixed solution, adjust the pH of the mixed solution to 10±0.5;

[0021] (2) Heat the mixed solution obtained in step (1) in a 60℃ water bath for 12 hours, and then use deionized water for centrifugal washing 3 times to obtain graphene oxide / layered double hydroxide (GO / LDHs) composite material ;

[0022] (3) Disperse GO / LDHs in 100mL ethanol, then add 50mL 3-aminopropyltriethoxysilane (APTES), reflux at 110°C for 2h, and stir. The concentration of GO / LDHs is 5mg / mL~10mg / mL, then centrifuge the product, wash with ethanol 3 times, and then vacuum dry;

[0023] (4) The modified GO / LDHs composite material was added to the 0.1M sodium vanadate aqueous solution of pH=8, and stirred at 40°C for 24h. Then ...

Embodiment 2

[0027] (1) 0.2g of graphene oxide was dispersed in 200mL of aqueous solution. After the ultrasonic dispersion was uniform, 0.1M zinc nitrate hexahydrate and 0.05M aluminum nitrate nonahydrate were added in sequence. After mixing well, 0.4M sodium nitrate was slowly added dropwise. And 0.2M sodium hydroxide mixed solution, adjust the pH of the mixed solution to 10±0.5;

[0028] (2) Heat the mixed solution obtained in step (1) in a 60℃ water bath for 12 hours, and then use deionized water for centrifugal washing 3 times to obtain graphene oxide / layered double hydroxide (GO / LDHs) composite material ;

[0029] (3) Disperse GO / LDHs in 100mL ethanol, then add 50mL 3-aminopropyltriethoxysilane (APTES), reflux at 110°C for 2h, and stir. The concentration of GO / LDHs is 5mg / mL~10mg / mL, then centrifuge the product, wash with ethanol 3 times, and then vacuum dry;

[0030] (4) The modified GO / LDHs composite material was added to a 0.15M sodium vanadate aqueous solution of corrosion inhibitor w...

Embodiment 3

[0034] (1) 0.2g of graphene oxide is dispersed in 250mL of aqueous solution, after ultrasonic dispersion is uniform, 0.1M zinc nitrate hexahydrate and 0.05M aluminum nitrate nonahydrate are added in sequence, after mixing evenly, 0.4M sodium nitrate is slowly added dropwise And 0.2M sodium hydroxide mixed solution, adjust the pH of the mixed solution to 10±0.5;

[0035] (2) Heat the mixed solution obtained in step (1) in a 60℃ water bath for 12 hours, and then use deionized water for centrifugal washing 3 times to obtain graphene oxide / layered double hydroxide (GO / LDHs) composite material ;

[0036] (3) Disperse GO / LDHs in 100mL ethanol, then add 50mL 3-aminopropyltriethoxysilane (APTES), reflux at 110°C for 2h, and stir. The concentration of GO / LDHs is 5mg / mL~10mg / mL, then centrifuge the product, wash with ethanol 3 times, and then vacuum dry;

[0037] (4) The modified GO / LDHs composite material was added to a 0.1M sodium vanadate aqueous solution of corrosion inhibitor at pH=9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com