Method for preparing nitrate intercalation cobalt and aluminum type hydrotalcite in one step through coprecipitation

A nitrate intercalation and hydrotalcite technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problem that nitrate intercalation cobalt-aluminum hydrotalcite cannot be prepared in one step, and achieve the effect of simple and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

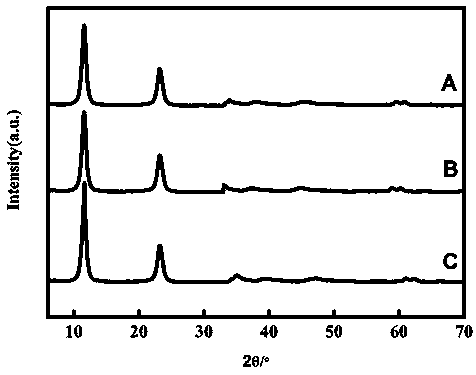

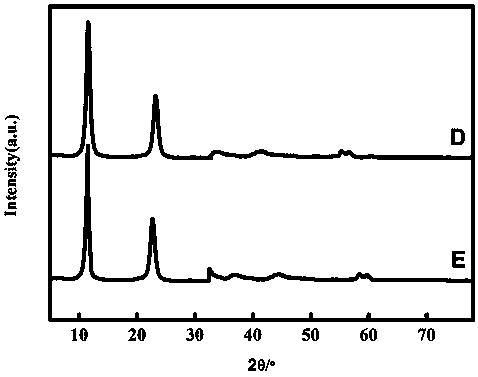

Embodiment 1

[0035] (1) Use a pipette to pipette 26.50±0.01 mL 0.2 mol·L -1 To 100 mL volumetric flask, and then add 73.50±0.01 mL 0.2 mol·L -1 Acetic acid solution, vortex to mix evenly, make 100 mL of acetic acid-sodium acetate buffer solution with pH=4.20±0.01 in constant volume.

[0036] (2) Weigh 31.43±0.01 g of cobalt nitrate hexahydrate and 20.26±0.01 g of aluminum nitrate nonahydrate, mix them into a beaker, add 90±1 mL of deionized water to the beaker, and stir with a magnetic stirrer for 10 min. Is completely dissolved, the prepared solution (c(Co 2+ )=1.20 mol·L -1 , C(Al 3+ )=0.60 mol·L -1 ) Transfer to a 250 mL bottle infusion set for later use.

[0037] (3) Weigh 4.00±0.01 g of sodium hydroxide into a beaker, add a small amount of deionized water to the beaker, and stir with a magnetic stirrer for 10 minutes to completely dissolve it. Transfer the dissolved solution to a 100 mL volumetric flask to make 1.00mol·L -1 Sodium hydroxide aqueous solution, then transfer it to a 250 mL bo...

Embodiment 2

[0042] (1) Use a pipette to pipette 59.00±0.01 mL 0.2 mol·L -1 To 100 mL volumetric flask, then add 41.00±0.01 mL 0.2 mol·L -1 Acetic acid solution, vortex to mix evenly, make 100 mL pH=4.80±0.01 acetic acid-sodium acetate buffer solution.

[0043] (2) Weigh 43.65±0.01 g of cobalt nitrate hexahydrate and 18.76±0.01 g of aluminum nitrate nonahydrate, mix them into a beaker, add 100±1 mL of deionized water to the beaker, and stir with a magnetic stirrer for 10 min. Is completely dissolved, the prepared solution (c(Co 2+ )=1.50 mol·L -1 , C(Al 3+ )=0.50 mol·L -1 ) Transfer to a 250 mL bottle infusion set for later use.

[0044] (3) Weigh 4.00±0.01 g of sodium hydroxide into a beaker, add a small amount of deionized water to the beaker, and stir with a magnetic stirrer for 10 minutes to completely dissolve it. Transfer the dissolved solution to a 100 mL volumetric flask to make 1.00mol·L -1 Sodium hydroxide aqueous solution, then transfer it to a 250 mL bottle infusion set for later u...

Embodiment 3

[0049] (1) Pipette 18.00±0.01 mL 0.2 mol·L with a pipette -1 To 100 mL volumetric flask, and then add 82.00±0.01 mL 0.2 mol·L -1 Acetic acid solution, vortex to mix evenly, make 100 mL pH=4.00±0.01 acetic acid-sodium acetate buffer solution.

[0050] (2) Weigh 27.94±0.01 g cobalt nitrate hexahydrate and 9.00±0.01 g aluminum nitrate nonahydrate, mix them into a beaker, add 120±5 mL deionized water to the beaker, and stir with a magnetic stirrer for 10 min. Is completely dissolved, the prepared solution (c(Co 2+ )=0.80 mol·L -1 , C(Al 3+ )=0.20 mol·L -1 ) Transfer to a 250 mL bottle infusion set for later use.

[0051] (3) Weigh 4.00±0.01 g of sodium hydroxide into a beaker, add a small amount of deionized water to the beaker, and stir with a magnetic stirrer for 10 minutes to completely dissolve it. Transfer the dissolved solution to a 100 mL volumetric flask to make 1.00mol·L -1 Sodium hydroxide aqueous solution, then transfer it to a 250 mL bottle infusion set for later use.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com