Catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and preparation method and application thereof

A dialkyl adipate and catalyst technology, which is applied in the preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc., can solve problems such as poor thermal stability, high catalyst cost, and high reaction pressure problem, to achieve the effect of increasing liquid hourly space velocity, simple preparation process, and reducing hydrogen-ester ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

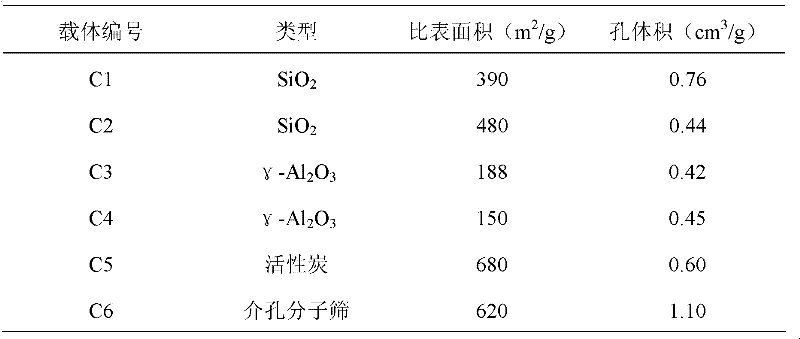

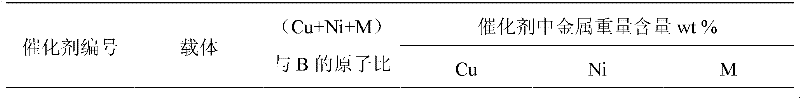

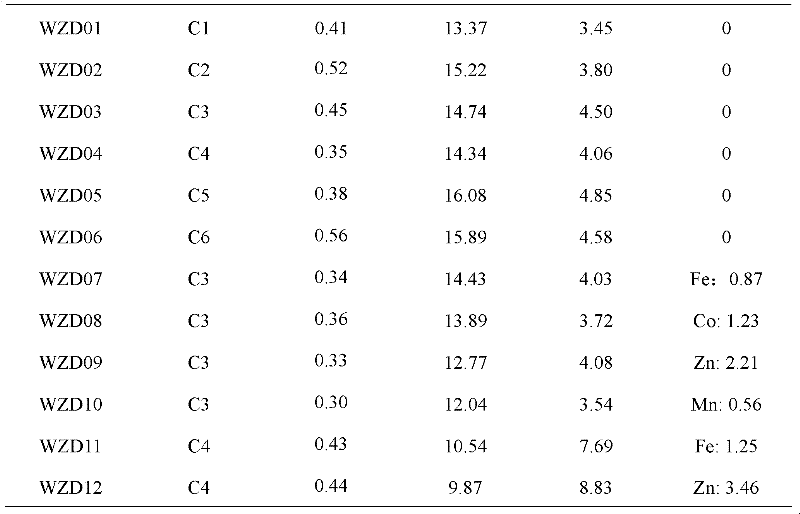

[0041] 2. Preparation of catalyst

[0042] Weigh a certain amount of the above-mentioned carriers respectively, and dry them at 80-120°C; then weigh a certain amount of soluble salts of copper, nickel, and metal additive M according to the ratio of each component in the catalyst, and you can choose nitrate and acetate etc.; and configured as an aqueous solution, the total concentration of solute contained in the solution is 10-30%wt, and a saturated solution is recommended; the carrier is immersed in the above metal solution according to the loading capacity, and the precursor is obtained after drying.

[0043] Configure a certain concentration of KBH 4 or NaBH 4 Solution, pH value 7-12, concentration 1-10mol / L. Add the solution dropwise to the precursor, and stir in a constant temperature water bath at 25-75°C. After no hydrogen is released, the reaction ends. Wash with distilled water until the conductivity of the filtrate is less than 100 μs / cm. The catalyst precursor ...

Embodiment 1

[0051] Effect of catalysts prepared with different supports on the hydrogenation of dimethyl adipate to hexanediol. The activity and selectivity of the catalysts were evaluated in a micro fixed bed reactor. The catalyst powder is granulated to 40-100 mesh, and the loading amount is 5g.

[0052] table 3

[0053]

[0054]

Embodiment 2

[0056] Effect of Metal Additive M on the Hydrogenation of Dimethyl Adipate to Hexylene Glycol. The activity and selectivity of the catalysts were evaluated in a micro fixed bed reactor. The catalyst powder is granulated to 40-100 mesh, and the loading amount is 5g.

[0057] Table 4

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com