Method for producing 1,6-hexandiol

A technology of hexanediol and adipic acid, applied in the field of production 1, can solve problems such as regeneration of exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

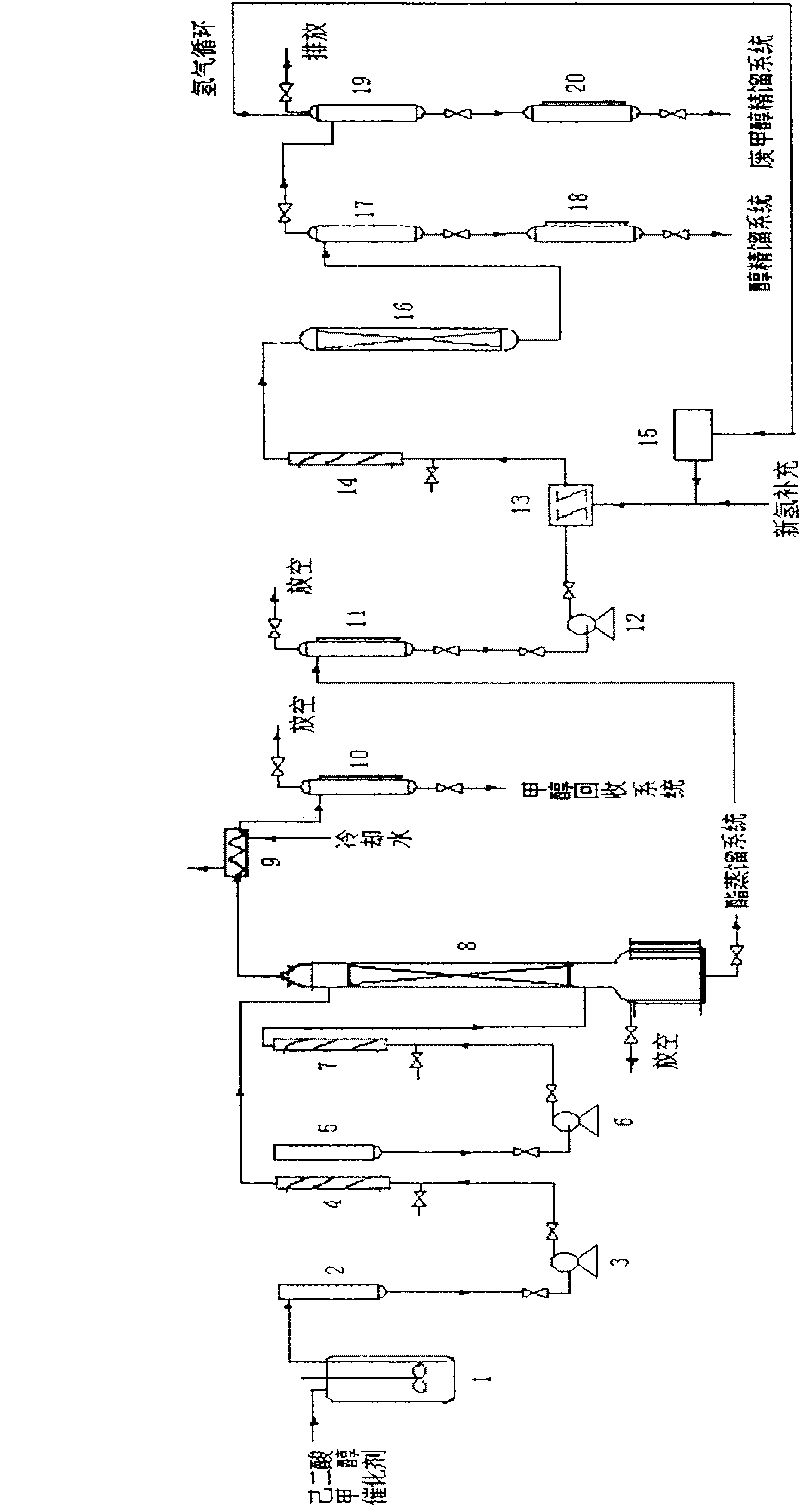

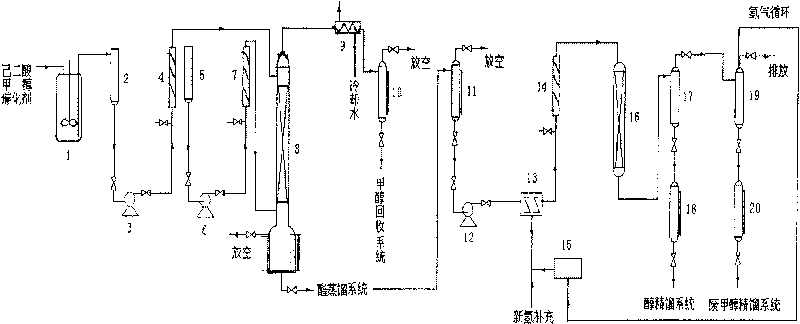

[0029] The process flow equipment of the present invention is described in detail according to the accompanying drawings. Process flow diagram as Figure 1 Show. The process operation is described as follows: first add a solid acid catalyst to the batch pre-esterification kettle 1, add the solid raw material adipic acid into the batch pre-esterification kettle 1 from the feeding port, and use a methanol pump to feed methanol from the middle of the raw material methanol The storage tank is added to the pre-esterification kettle to carry out the pre-esterification reaction. In normal operation, the solid acid catalyst is stored in the kettle for repeated use. The pre-esterification tank is heated, and the methanol vapor is condensed and then refluxed into the pre-esterification tank during the reaction. After the pre-esterification reaction is completed, the supernatant liquid of the reaction product is sent to the raw material storage tank 2 after sampling and analysis. The...

Embodiment 2

[0031] Add solid acid catalyst, adipic acid and methanol in the esterification kettle, heat and stir at normal pressure, and carry out pre-esterification reaction. The amount of catalyst added is based on the quality of adipic acid. The specific results are as follows:

[0032] Table 1 The results of pre-esterification experiments with different catalyst additions

[0033] Catalyst addition

Embodiment 3

[0035] Utilize the product of embodiment 2 to carry out continuous esterification, normal pressure, under the condition of 70~150 ℃, concrete result is as follows:

[0036] Table 2 Results of continuous esterification experiments with different reactor length-to-diameter ratios

[0037] Reactor aspect ratio

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com