Preparation method of nanometer carbon-based solid acid

A technology of carbon-based solid acid and solid acid, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high preparation cost, large-scale production and application of bound solid acid catalysts, and product application range Narrow problems, to achieve the effect of mild reaction conditions, energy saving, easy large-scale production, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

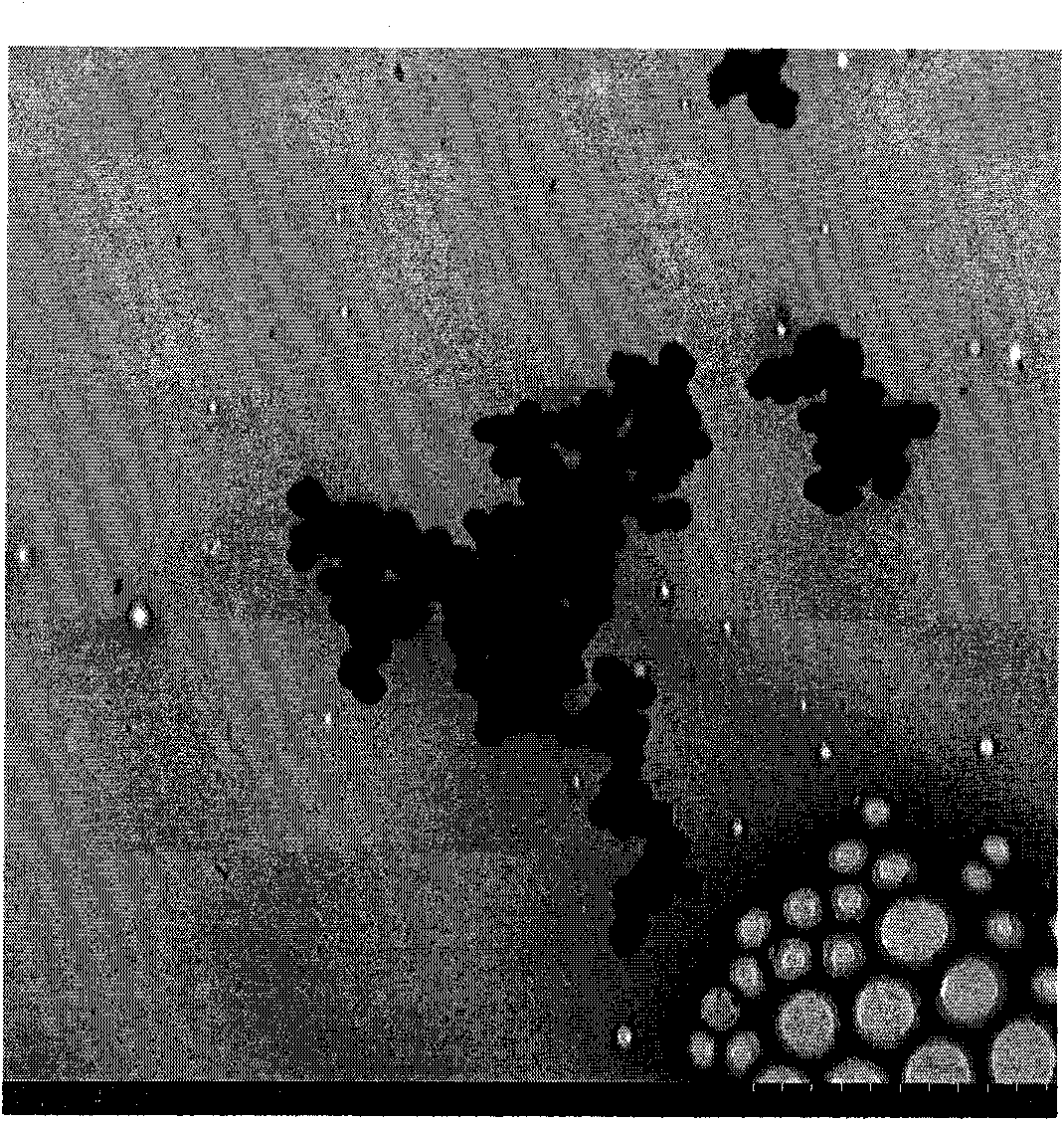

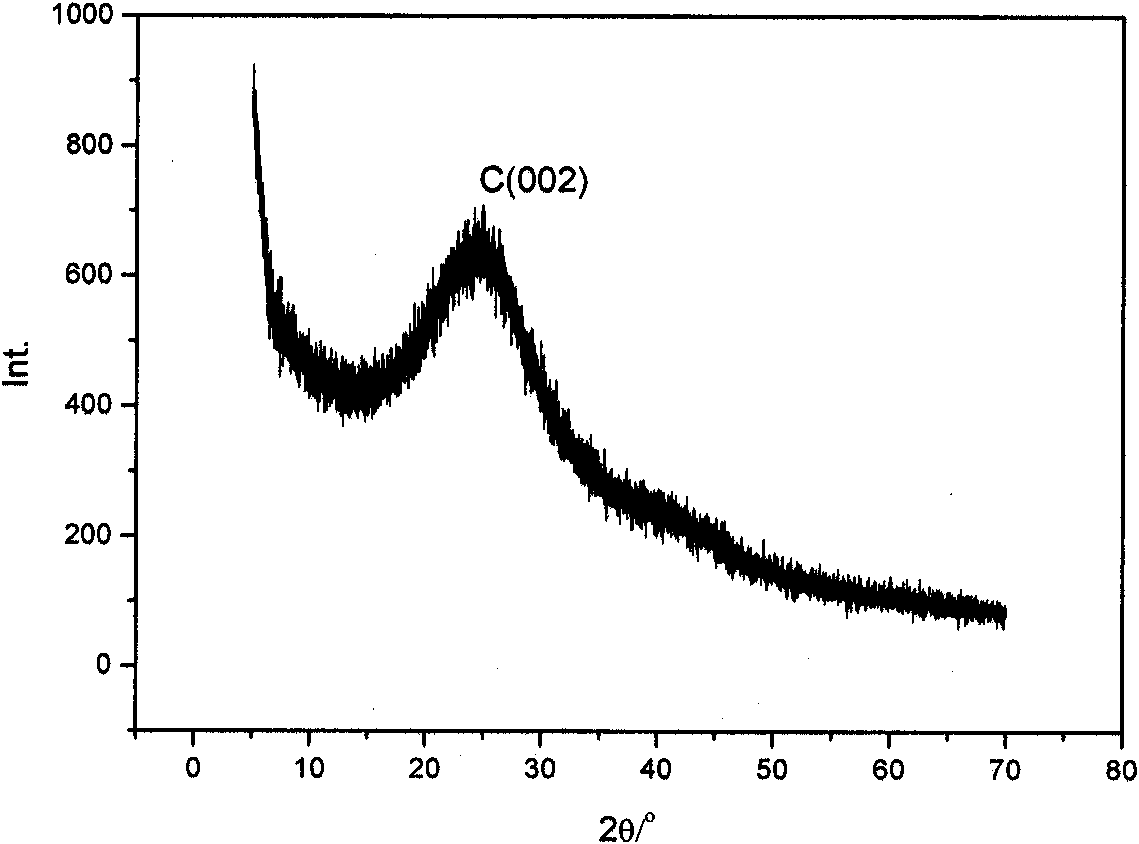

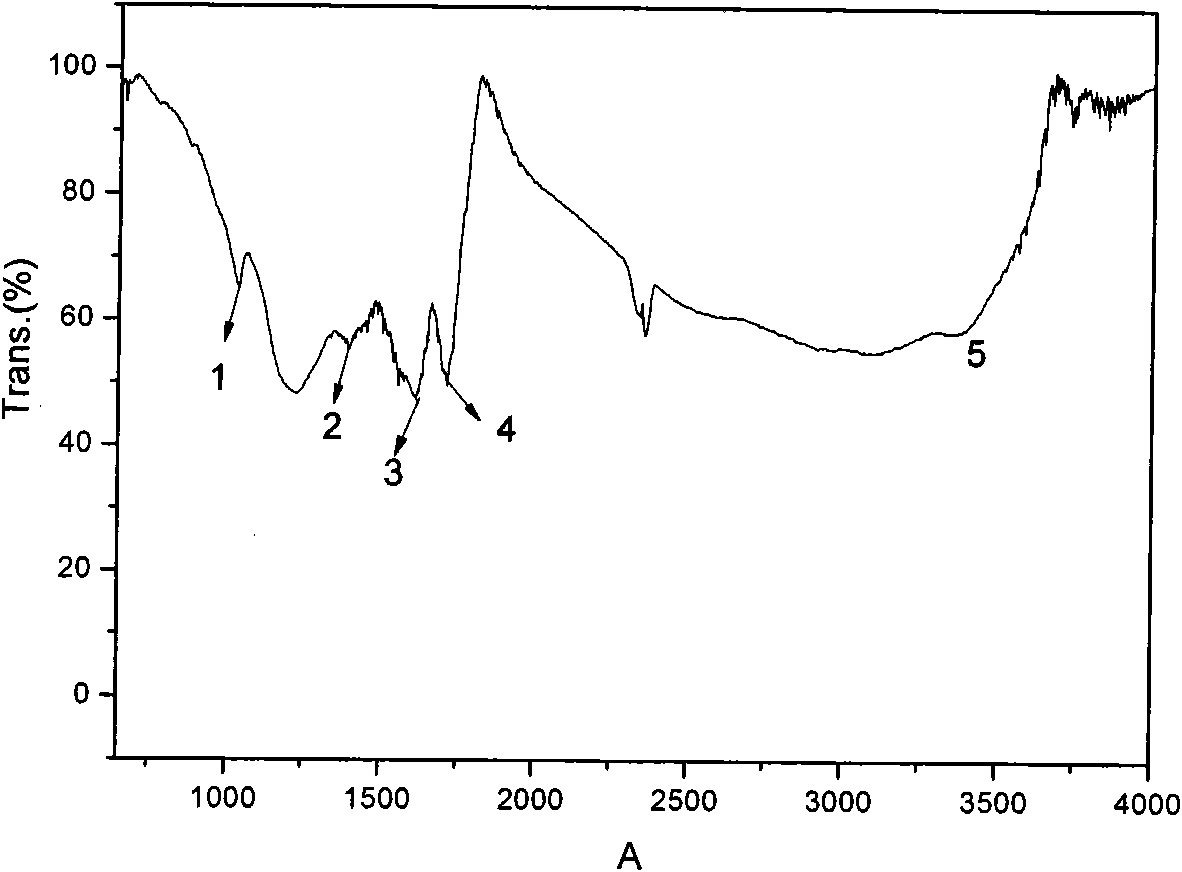

Embodiment 1

[0043] Take 4g of glucose, dissolve it in 40ml of water and stir until it becomes clear, add it to the reaction kettle and keep it warm for 10h at 175°C, take out the reaction kettle, filter and wash it, and dry it in an oven at 80°C for 12h to obtain a brown-red powder solid. Put the carbon material into a reaction kettle or a three-necked flask to react with concentrated sulfuric acid at 150°C for 15 hours, filter and wash the reactant with 100ml of boiling water to obtain a black powder solid acid. Take 0.2g of the above-mentioned solid acid and add it to a 100ml three-neck flask, then add 58.3ml of absolute ethanol, 5.7ml of acetic acid, and react in an oil bath at 70°C for 6h, the conversion rate of acetic acid is 60%, and the rate of ethyl acetate formation is 0.67mmol / min / g.

Embodiment 2

[0045] Take 4g of glucose, dissolve it in 40ml of water and stir until it becomes clear, add it to the reaction kettle and keep it warm for 10h at 175°C, take out the reaction kettle, filter and wash it, and dry it in an oven at 80°C for 12h to obtain a brown-red powder solid. Put the carbon material into a reaction kettle or a three-necked flask to react with 20% oleum at 120°C for 15 hours, filter and wash the reactant with 100ml of boiling water to obtain a black powder solid acid. Take 0.2g of the above-mentioned solid acid and add it to a 100ml three-neck flask, then add 58.3ml of absolute ethanol, 5.7ml of acetic acid, and react in an oil bath at 70°C for 3h, the conversion rate of acetic acid is 83%, and the rate of ethyl acetate generation is 2.10mmol / min / g.

Embodiment 3

[0047] Get 0.1g of the solid acid gained in Example 2, join in the 100ml three-necked flask, then add dehydrated ethanol 58.3ml, acetic acid 5.7ml, oil bath 70 ℃ of reaction 4h, acetic acid conversion rate is 73%, ethyl acetate generation rate is 3.13 mmol / min / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com