Light-cured three dimensional printing material and preparation method thereof

A 3D printing and light curing technology, applied in the field of polymer composite materials, can solve problems such as deformation of cured products, restrictions on the promotion and use of 3D printing technology, and difficulties in the movement of the main chain, and achieve the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

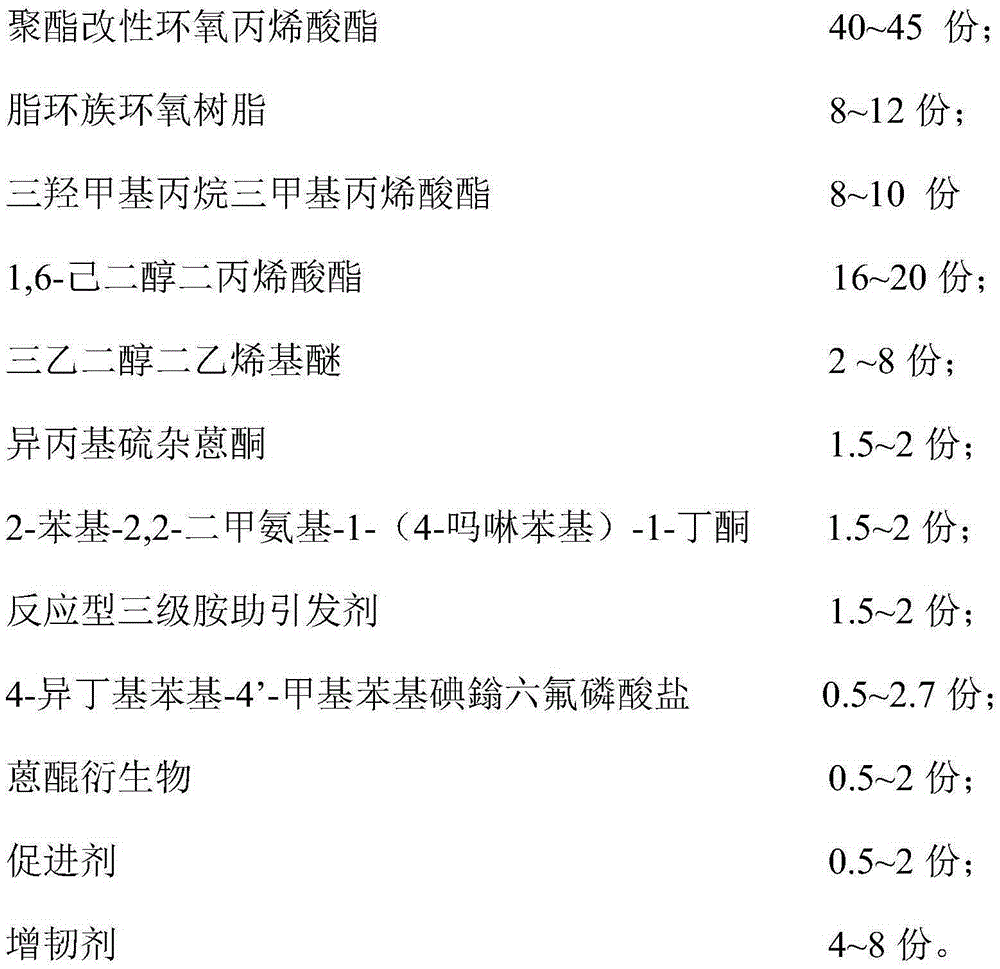

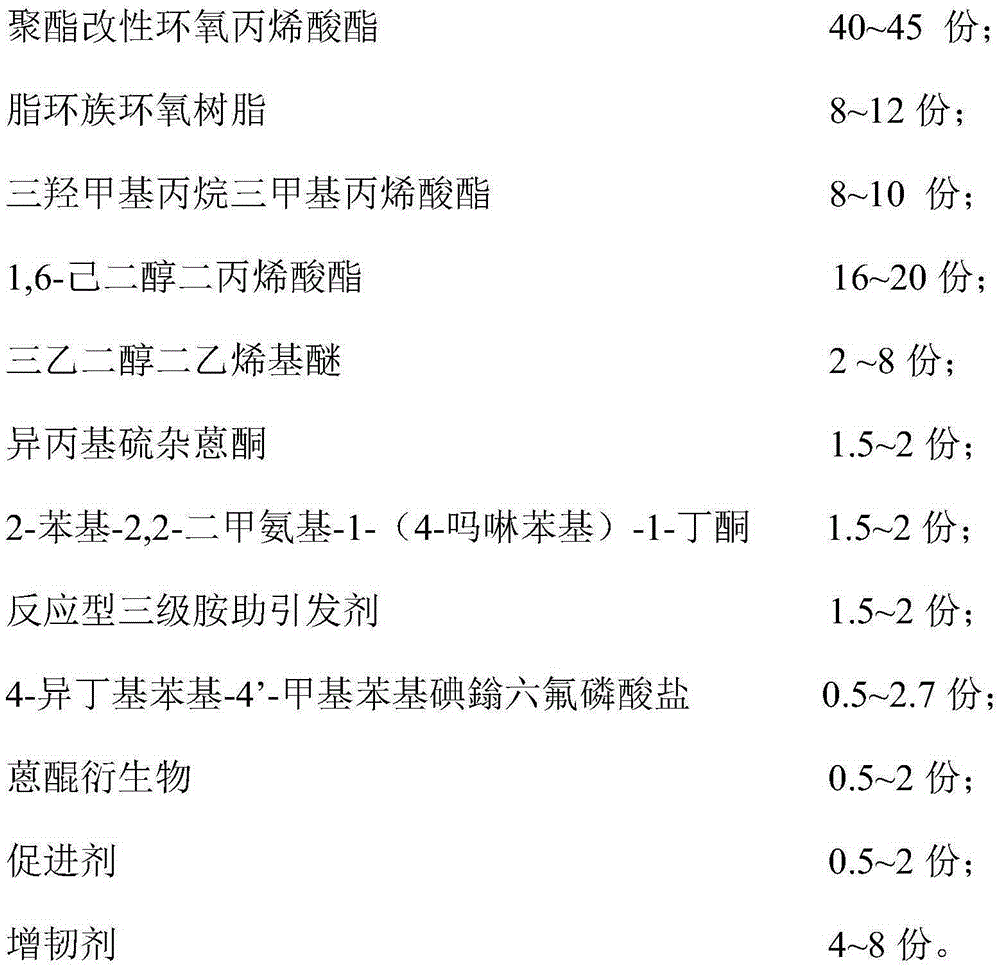

[0018] 1. In parts by mass, prepare raw materials as shown in Table 1.

[0019] Table 1 Embodiment 1 each raw material proportioning

[0020] raw material

Example 1

Polyester Modified Epoxy Acrylate

40 copies

Aliphatic epoxy resin

12 copies

Trimethylolpropane trimethacrylate

8 servings

20 copies

Triethylene glycol divinyl ether

2 copies

2 copies

2-Phenyl-2,2-dimethylamino-1-(4-morpholinephenyl)-1-butanone

1.5 servings

Reactive tertiary amine co-initiator 6420

2 copies

4-Isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate

1.5 servings

Sensitizer anthraquinone derivative PAS-12

2 copies

Accelerator Polyol PAS-33

1 copy

Toughener epoxidized hydroxyl-terminated polybutadiene EHTPB

8 servings

[0021] 1.1 Preparation method:

Embodiment 2

[0031] 2. In parts by mass, prepare raw materials as shown in Table 3

[0032] Table 3 embodiment 2 each raw material ratio

[0033] raw material

Example 2

Polyester Modified Epoxy Acrylate

43.5 servings

Aliphatic epoxy resin

9 servings

Trimethylolpropane trimethacrylate

9 servings

18 copies

Triethylene glycol divinyl ether

5 copies

1.5 servings

2-Phenyl-2,2-dimethylamino-1-(4-morpholinephenyl)-1-butanone

2 copies

Reactive tertiary amine co-initiator

1.7 servings

4-Isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate

0.5 parts

Sensitizer anthraquinone derivative PAS-12

1.8 servings

Accelerator Polyol PAS-33

2 copies

Toughener epoxidized hydroxyl-terminated polybutadiene EHTPB

6 servings

[0034] 2.1 Preparation method:

[0035] A) In parts by mass, 18 parts of diluent 1,6-he...

Embodiment 3

[0044] 3. In parts by mass, prepare raw materials as shown in Table 5

[0045] Each raw material ratio of table 5 embodiment 3

[0046] raw material

[0047] 3.1 Preparation method:

[0048] A) In parts by mass, 16 parts of diluent 1,6-hexanediol diacrylate, 10 parts of trimethylolpropane trimethacrylate and 8 parts of triethylene glycol divinyl ether, photoinitiator 1.9 parts of isopropylthioxanthone, 1.9 parts of 2-phenyl-2,2-dimethylamino-1-(4-morpholinephenyl)-1-butanone and 4-isobutylphenyl-4 2.7 parts of '-methylphenyl iodonium hexafluorophosphate, 1.5 parts of reactive tertiary amine co-initiator, 0.5 part of sensitizer anthraquinone derivative and 0.5 part of accelerator polyol compound are added to the beaker and heated Stir on a magnetic stirrer for 2 hours.

[0049] B) In terms of parts by mass, add 45 parts of prepolymer polyester modified epoxy acrylate, 8 parts of alicyclic epoxy resin and 4 parts of toughening agent epoxidized hydroxyl-terminated po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com