Method for preparing light reflecting leather

A kind of leather and reflective technology, which is applied in the direction of special leather manufacturing, leather impregnation, leather surface treatment, etc., to achieve the effect of improving the uniformity of wrestling patterns, improving permeability and preventing surface changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

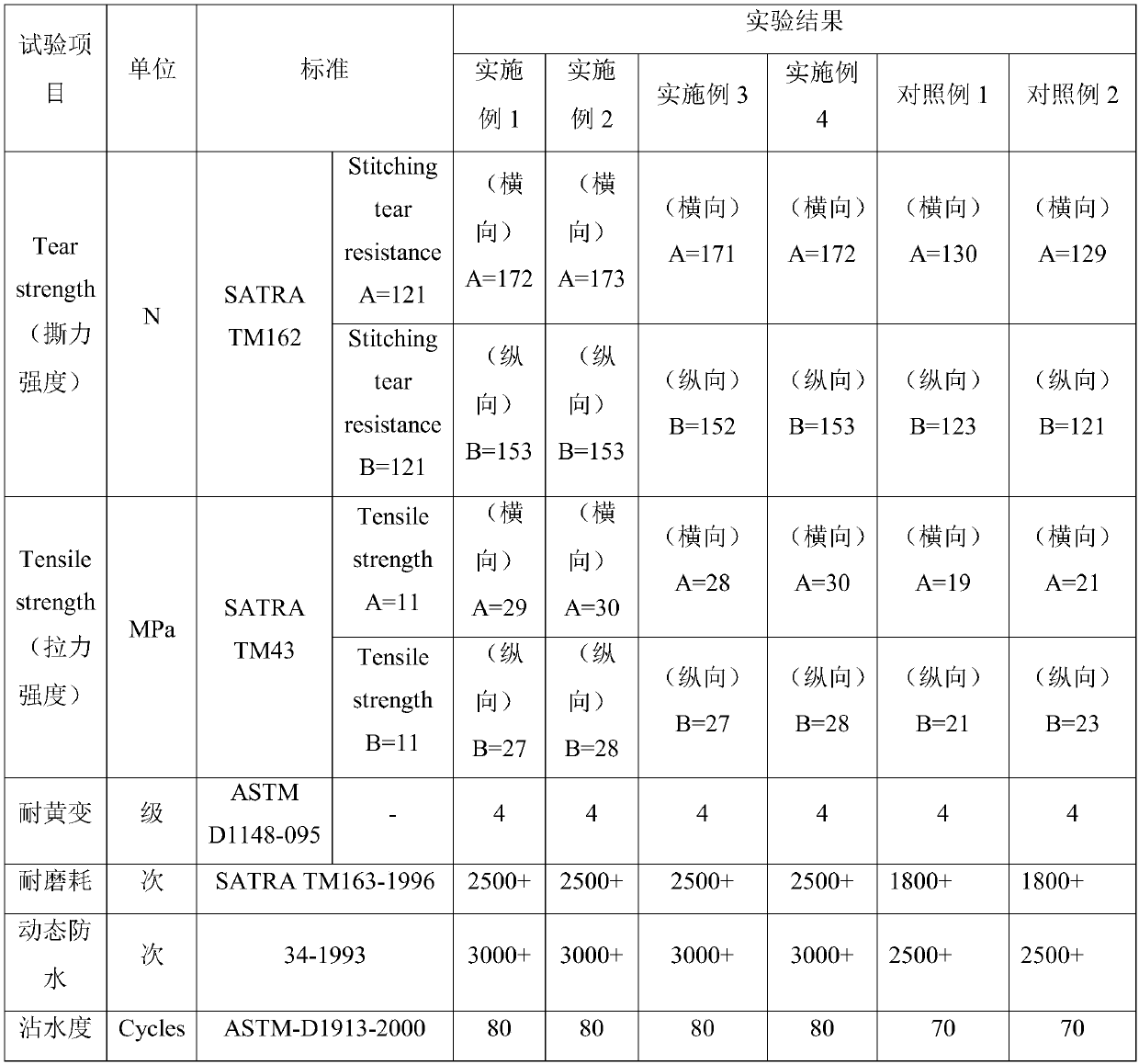

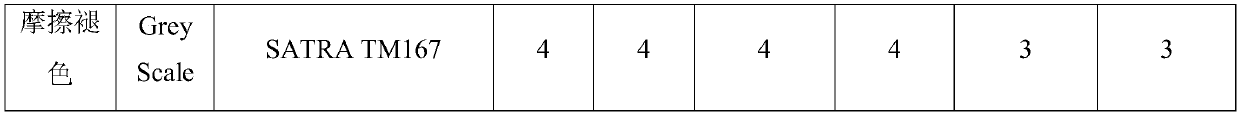

Examples

Embodiment 1

[0041] The preparation method of reflective leather comprises the following steps:

[0042] Throw the leather base into the drum, and go through water return, retanning and suede, neutralization, pre-esterification, dyeing, esterification and color fixation, product surface treatment and secondary treatment in order to obtain reflective leather. Among them, the two The secondary treatment includes the following steps: secondary water return, secondary esterification, secondary dyeing, secondary color fixing, drying and softening.

[0043] The water return process is as follows: put 200% of 40°C water, 0.4% OC and 0.5% rehumidifying agent into the drum according to the mass percentage of the skin base, and put 1% ammonium sulfate into the drum after running for 60 minutes. Put it into the drum, and after the drum runs for 90 minutes, put 0.7% phosphoglyceride, 0.1% polyoxyethylene, 1% softening enzyme, 0.6% oxalic acid and 0.4% formic acid into the drum. The liquid is discharg...

Embodiment 2

[0056] The preparation method of reflective leather comprises the following steps:

[0057] Throw the leather base into the drum, and go through water return, retanning and suede, neutralization, pre-esterification, dyeing, esterification and color fixation, product surface treatment and secondary treatment in order to obtain reflective leather. Among them, the two The secondary treatment includes the following steps: secondary water return, secondary esterification, secondary dyeing, secondary color fixing, drying and softening.

[0058] The water return process is as follows: put 210% of 42°C water, 0.5% OC and 0.6% rehumidifying agent into the drum according to the mass percentage of the skin base, and put 2% ammonium sulfate into the drum after running for 62 minutes. Put it into the drum, and after the drum runs for 92 minutes, put 0.8% phosphoglyceride, 0.2% polyoxyethylene, 2% softening enzyme, 0.7% oxalic acid and 0.5% formic acid into the drum. After the drum runs for...

Embodiment 3

[0071] The preparation method of reflective leather comprises the following steps:

[0072] Throw the leather base into the drum, and go through water return, retanning and suede, neutralization, pre-esterification, dyeing, esterification and color fixation, product surface treatment and secondary treatment in order to obtain reflective leather. Among them, the two The secondary treatment includes the following steps: secondary water return, secondary esterification, secondary dyeing, secondary color fixing, drying and softening.

[0073] The water return process is as follows: put 220% of 48°C water, 0.6% OC and 0.7% rehumidifying agent into the drum according to the mass percentage of the skin base, and put 2% ammonium sulfate into the drum after running for 68 minutes. Put it into the drum, and after the drum runs for 98 minutes, put 0.9% phosphoglyceride, 0.3% polyoxyethylene, 3% softening enzyme, 0.8% oxalic acid and 0.6% formic acid into the drum. After the drum runs for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com