Patents

Literature

39 results about "Phosphoglyceride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phospholipid in which the phosphate group of a phosphatidic acid is joined in ester linkage to an alcohol moiety; major components of cell membranes.

Compound feed for Macrobrachium rosenbergii

InactiveCN101589770ASatisfy nutritionMeet growth needsClimate change adaptationAnimal feeding stuffDiseaseAnimal science

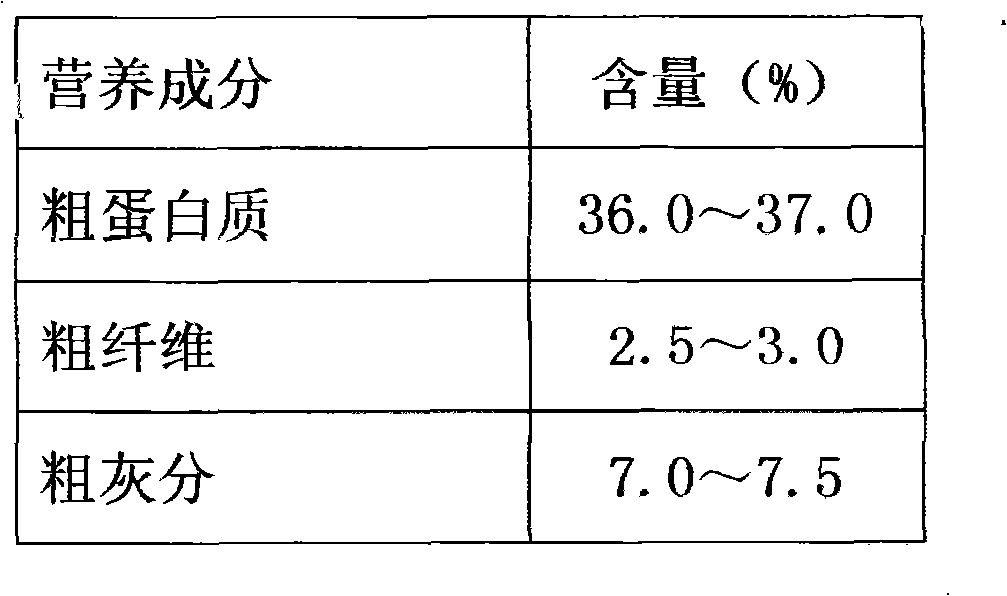

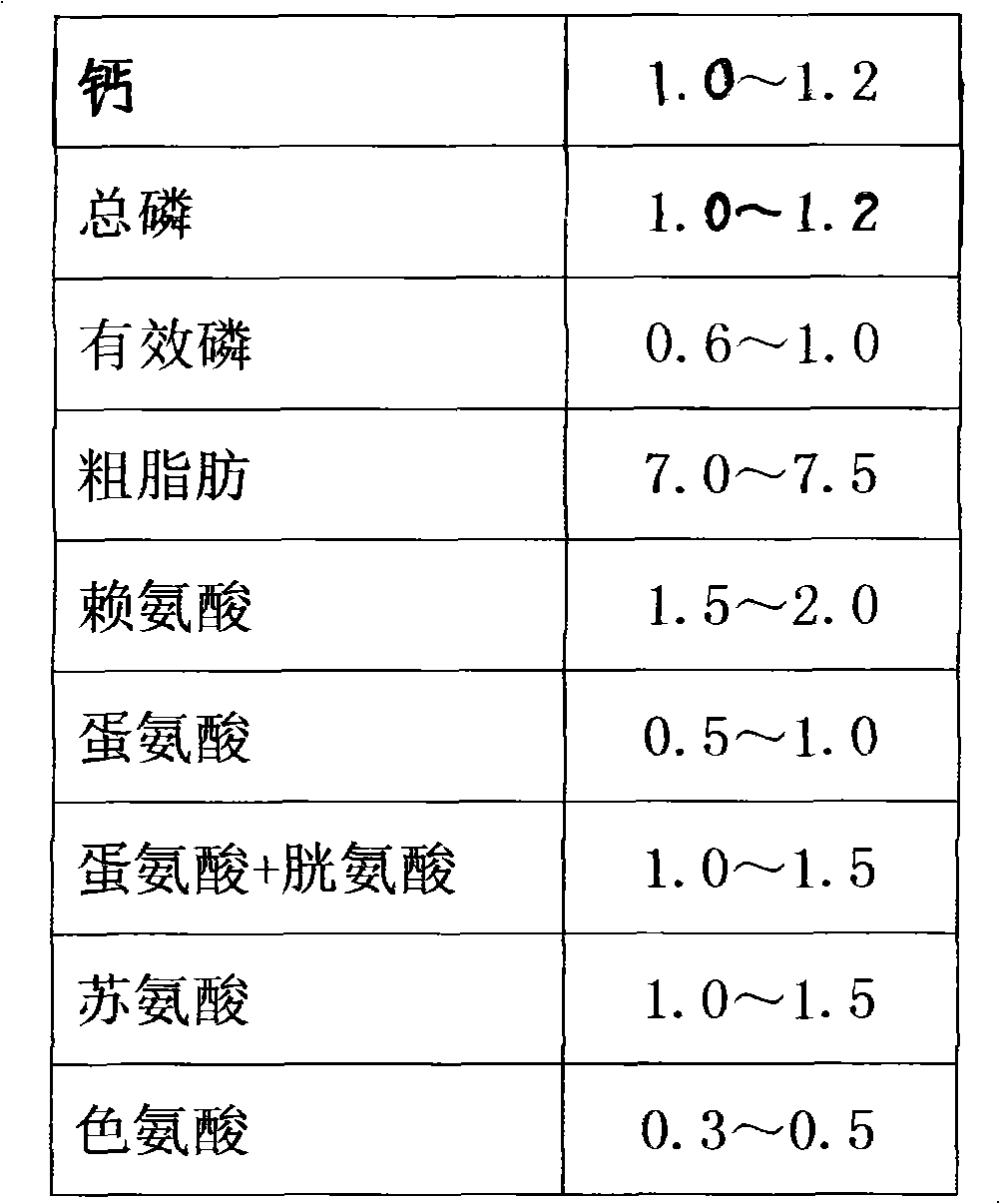

The invention relates to a compound feed for Macrobrachium rosenbergii, which comprises the following compositions: 46 percent CP bean meal, imported steam fish meal, peanut meal, squid paste, yeast extract, rapeseed meal, beer yeast, monocalcium phosphate, 60 percent CP corn protein powder, Tanimoto powder, special powder, shrimp multi-vitamin, shrimp multi-mineral, phosphoglyceride, imported fish oil, zeolite powder and mildewcide. The compound feed for Macrobrachium rosenbergii has the following advantages that: (1) a scientific formula and comprehensive nutrition: the superior beam meal, rapeseed meal, peanut meal, corn protein powder, special powder and other main materials are adopted and scientifically matched with shrimp multi-vitamin, mineral and other added compositions, besides the abundant energy compositions, the feed also contains abundant protein, amino acid and various nutritional compositions and can meet the nutritional and growing requirements of Macrobrachium rosenbergii, and the feed can also allow Macrobrachium rosenbergii to rapidly grow and have strong disease resistance; and (2) low cost: the bean meal, the rapeseed meal, the peanut meal and the like are used as main materials and greatly reduce the product cost.

Owner:江苏海辰科技集团有限公司

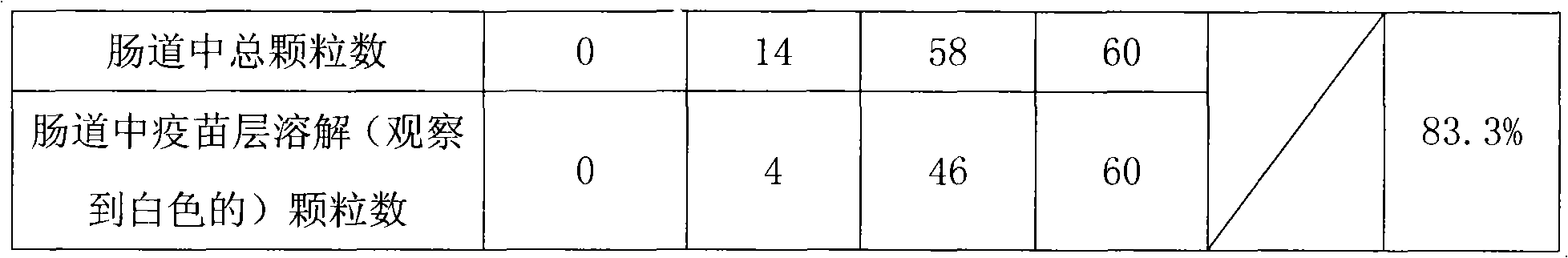

Enteric oral vaccine for fishing gear and preparation method thereof

InactiveCN101283985AImprove immune efficiencyImprove the adhesion firmnessPharmaceutical non-active ingredientsGranular deliveryPolyvinyl alcoholPolyethylene glycol

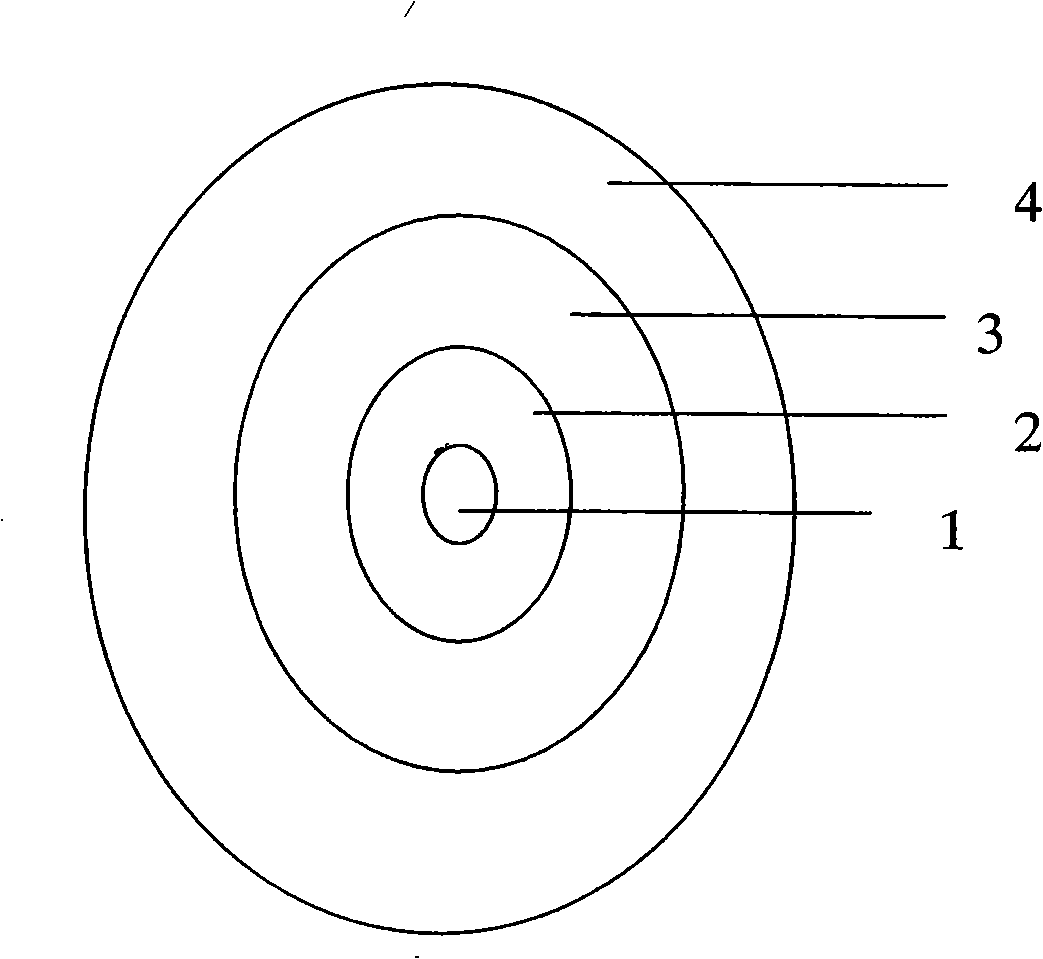

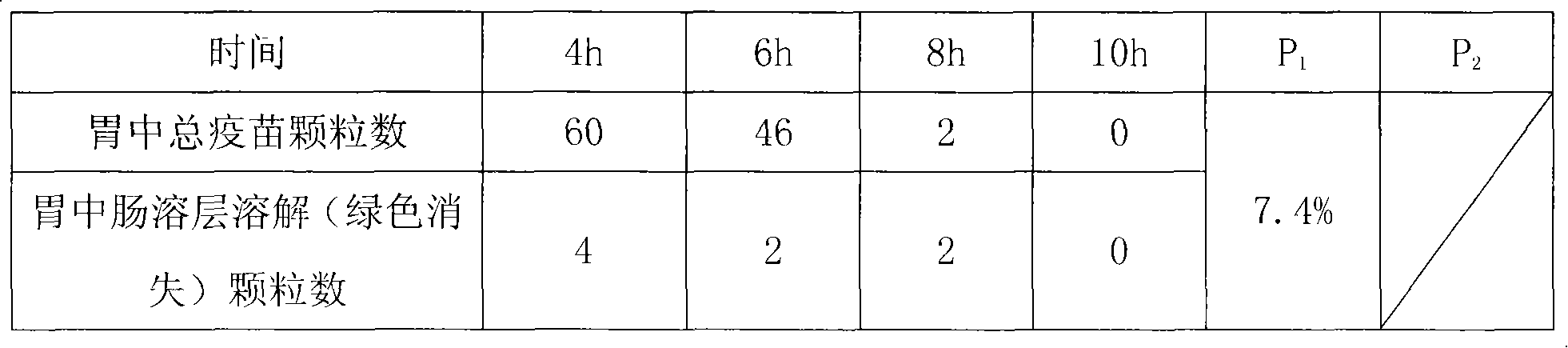

The invention relates to an enteric-coated oral vaccine for fishing, belonging to the field of oral vaccines for fishing. The enteric-coated oral vaccine for fishing comprises particles or pellets sprayed with a vaccine layer and sequentially coated with an isolating layer and an enteric-coated layer outside the vaccine layer. A dry powder composition A for spraying vaccine and coating the isolating layer comprises the following components (by weight parts) one or more film-forming agents selected from hydroxypropyl methylcellulose, polyvinyl alcohol and polyvinyl pyrrolidone 40-60 parts, one or more plasticizing agents selected from phosphoglyceride, triethyl citrate and polyethylene glycol 3-10 parts, one or more antisticking agents selected from silicon dioxide, magnesium stearate, talcum powder and titanium oxide 30-50 parts, and surfactant selected from lecithin and Tween-80 0-5 parts. The vaccine can be directionally released in intestinal tract.

Owner:天津市水产研究所 +1

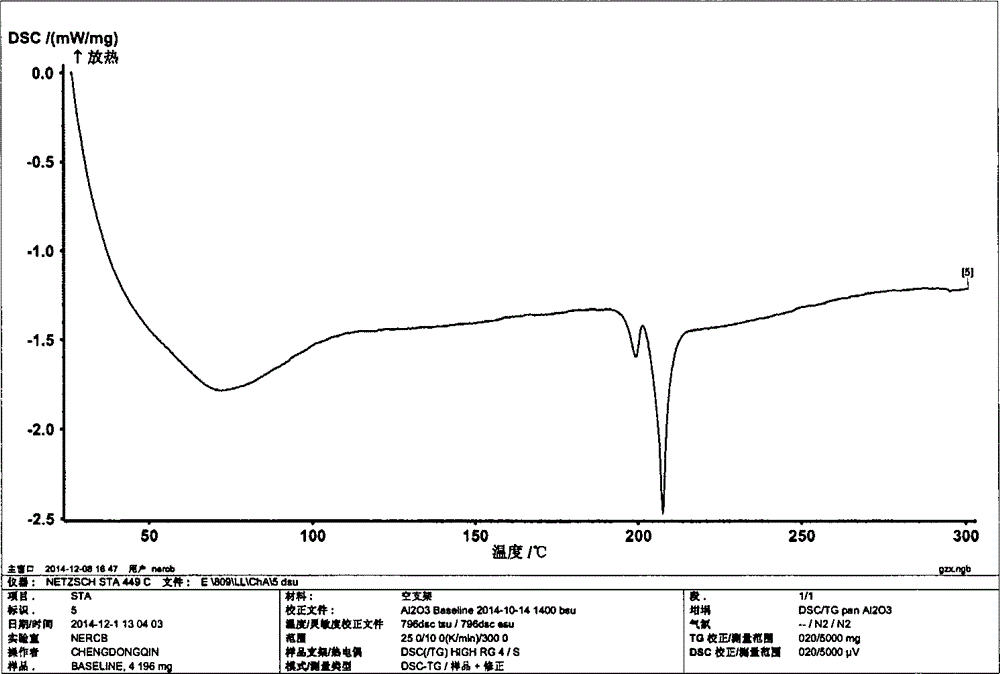

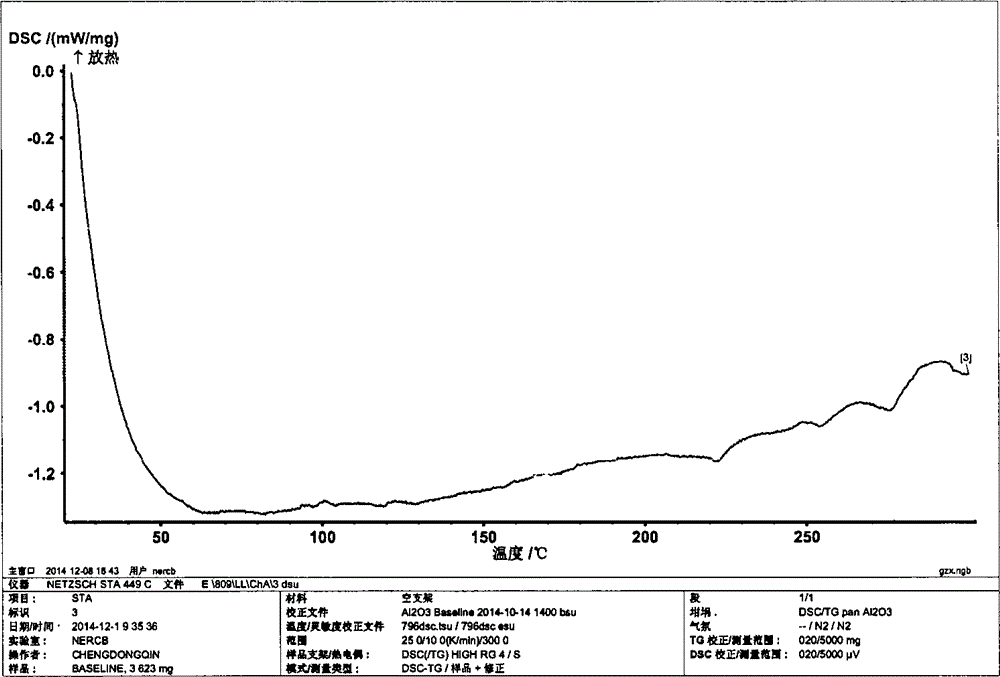

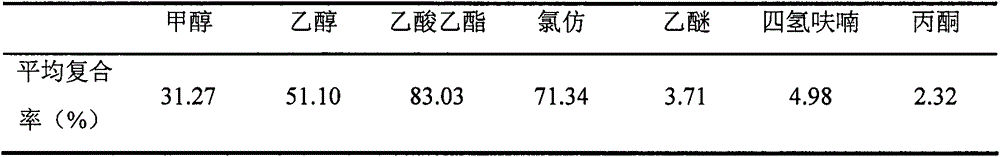

Application of lipid-modified substance of chlorogenic acid and derivative thereof

InactiveCN104826118AImprove lipophilicityImprove bioavailabilityAntibacterial agentsOrganic active ingredientsLipid formationPurification methods

The invention provides a lipid-modified substance of chlorogenic acid and a derivative thereof, and a preparation and purification method of the lipid-modified substance, wherein the lipid-modified substance includes the chlorogenic acid or the derivative thereof and phosphoglyceride. A preparation process includes steps of performing constant-temperature magnetic stirring reflux for a certain time to the chlorogenic acid or the derivative thereof and the phosphoglyceride with an aprotic solvent and drying an obtained reaction liquid to obtain a crude product. A purification process includes the steps of re-dissolving the crude product with filtration to obtain a filtrate and then drying the filtrate. The lipid-modified substance of the chlorogenic acid and the derivative thereof is high in composition rate and can significantly improve the fat-solubility of the chlorogenic acid and the derivative thereof, so that a subsequent preparation is convenient to process and shape. The lipid-modified substance can be used as an intermediate for preparing a lipidosome, nano particles, polymer micelles or a dendritic polymer and the like nano drug-delivery systems and micro emulsion, self-micro emulsion and the like micron drug-delivery systems, thereby enhancing in-vivo absorption of the chlorogenic acid and the derivative thereof and further increasing the bioavailability of the medicines in a preparation.

Owner:任静 +1

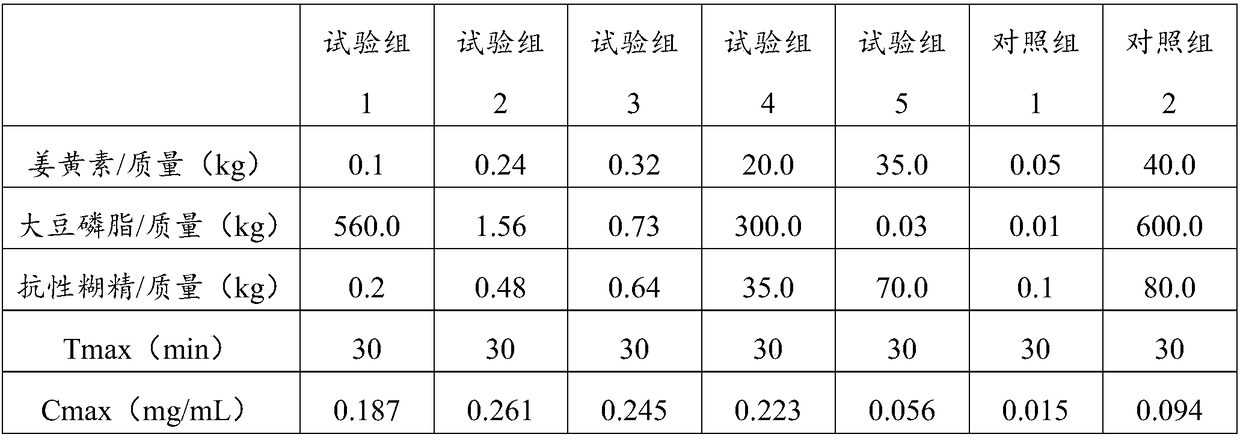

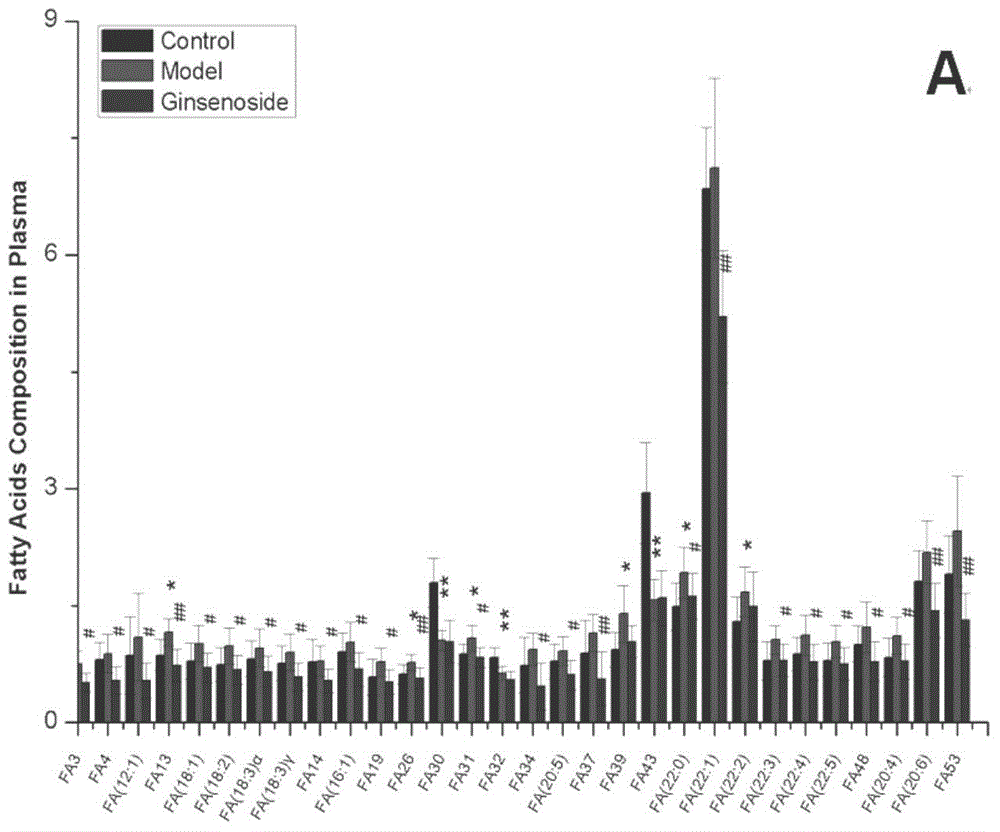

Composition for enhancing water solubility of curcumin and preparation method of composition

ActiveCN109481689ADoes not affect propertiesGood water solubilityAntipyreticAnalgesicsSolubilityWater soluble

The invention relates to a composition for enhancing the water solubility of curcumin and a preparation method of the composition and belongs to the technical field of foods and health-care products.The composition provided by the invention comprises the following components in parts by weight: 0.1 to 35.0 parts of the curcumin or a derivative thereof, 0.03 to 560.0 parts of phospholipid containing glycerol phosphate or the glycerol phosphate and 0.2 to 70.0 part of resistant dextrin. In the composition provided by the invention, the dissolution rate and the releasing rate of the composition,and the in-vivo transportation efficiency and the bioavailability of the curcumin are cooperatively enhanced through the glycerol phosphate and the resistant dextrin, and the intestinal absorption condition of the lipid-soluble curcumin is improved; and the types and forms, and a functional application range of a curcumin solid preparation are expanded under the condition that original propertiesand anti-oxidization performance of the curcumin are not influenced.

Owner:GUANGZHOU HANFANG PHARMA

Leather softening agent

InactiveCN104846128AGood flexibilityFeel goodPre-tanning chemical treatmentLeather surface finishingPolymer scienceSolvent

The invention relates to a leather softening agent which is prepared from the following raw materials in parts by weight: 6-14 parts of acrylate, 3-11 parts of lauryl sodium sulfate, 4-10 parts of ammonium persulfate, 3-9 parts of ethanol, 4.5-10 parts of phosphoglyceride, 6-13 parts of ethylene-vinyl acetate copolymer, 2-8 parts of sulfonated grease, 2-7 parts of solvent, 2-6 parts of emulsifier, 3.5-10 parts of fatty alcohol polyethenoxy ether, 4-10 parts of mildew preventive, 3-10 parts of jojoba wax and 3-8 parts of ethyl methyl p-hydroxybenzoate. The leather softening agent can well enhance the softness and hand feeling of the leather, improves the air permeability of the leather and prolongs the service life.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Waterproof anti-crack environment-friendly coating and preparation method thereof

InactiveCN105153829AImprove waterproof performanceImprove crack resistancePolyether coatingsCellulosePhosphoric Acid Esters

The invention discloses a preparation method of waterproof anti-crack environment-friendly coating. The preparation method comprises the following steps: mixing 35 to 55 parts of attapulgite, 12 to 16 parts of sericite, and 10 to 17 parts of titanium dioxide to obtain a mixture I, putting the mixture I into a grinding machine for grinding, so as to obtain a substance A; adding the substance A, 20 to 30 parts of a styrene-acrylic emulsion and 11 to 18 parts of polyethylene glycol into a stirring device, and carrying out stirring at 60 to 80 DEG C for reaction, so as to obtain a substance B; adding 8 to 15 parts of betulin, 12 to 16 parts of hydroxypropyl methyl cellulose, and 7 to 13 parts of phosphoglyceride into the substance B in sequence under the condition that stirring is carried out continuously, and carrying out a primary reaction at 80 to 100 DEG C; adding 2 to 8 parts of silver oxide, 3 to 7 parts of zinc sulfate, and 2 to 7 parts of carbohydrazide, and carrying out a secondary reaction for 40 to 60 minutes; carrying out cooling and drying to obtain the waterproof anti-crack environment-friendly coating. The waterproof anti-crack environment-friendly coating prepared according to the preparation method not only has application properties of common coating, but also is environment-friendly, generates no pollution to human bodies and the ambient environment, and is excellent in water resistance and anti-crack property, and wide in application prospect.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

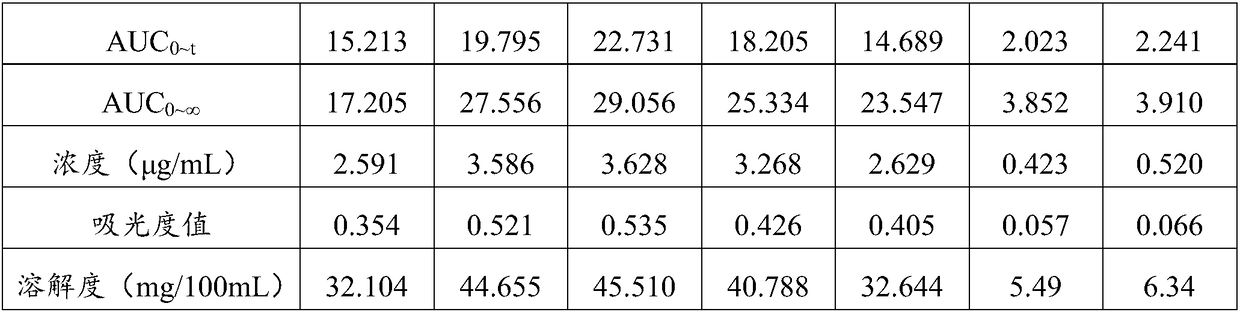

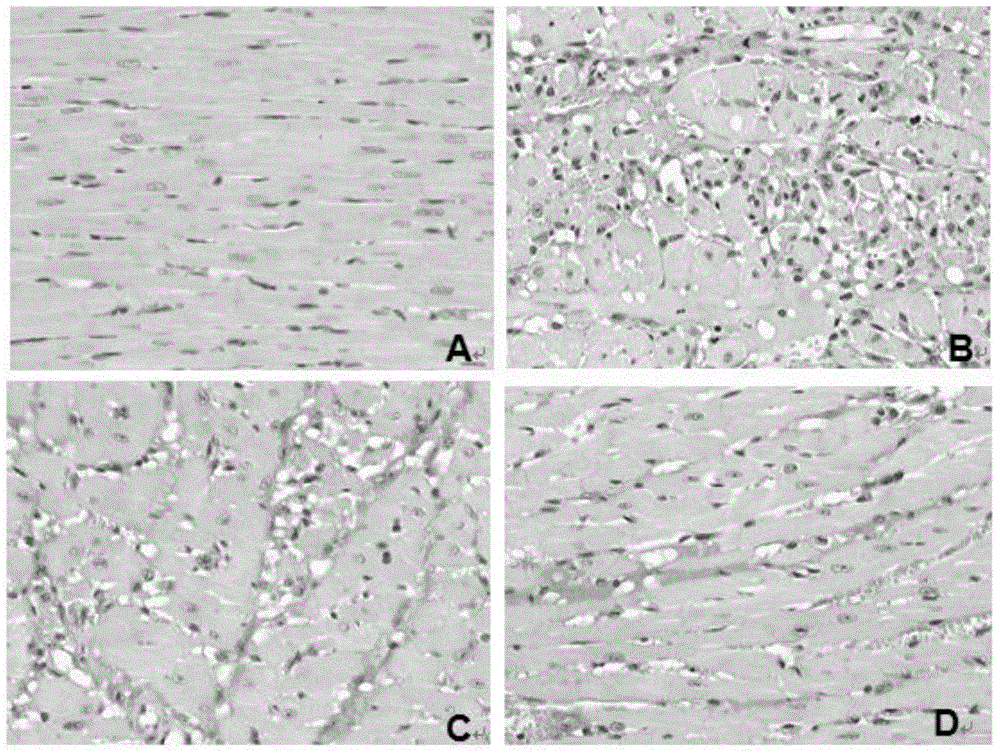

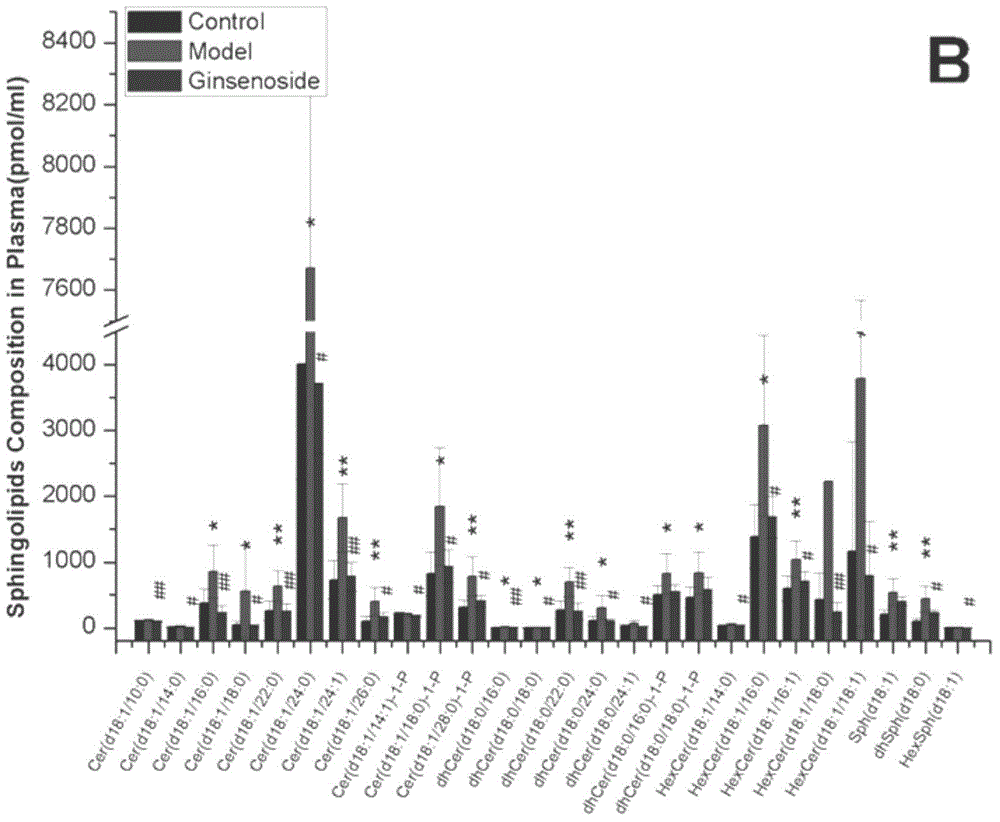

Application of total secondary ginseng glucoside in preparation of medicine for treating and/or preventing abnormal lipids metabolism after myocardial ischemia

The invention relates to an application of total secondary ginseng glucoside, Rg3, Rg5 and / or Rk1 in preparation of a medicine for treating and / or preventing abnormal lipids metabolism after myocardial ischemia, and concretely relates to an application of total secondary ginseng glucoside, Rg3, Rg5 and / or Rk1 in preparation of the medicine for regulating fatty acid, sphingolipid, phosphoglyceride and glyceride levels in blood or cardiac muscle tissue after myocardial ischemia. The application of the invention makes a research of the protective effects of total secondary ginseng glucoside to heart of mice with myocardial ischemial injury from an angle of lipidomics, reveals mechanism of total secondary ginseng glucoside, and provides a brand new approach for treating myocardial ischemial injury.

Owner:SHANGHAI HONGYITANG BIOPHARM CO LTD

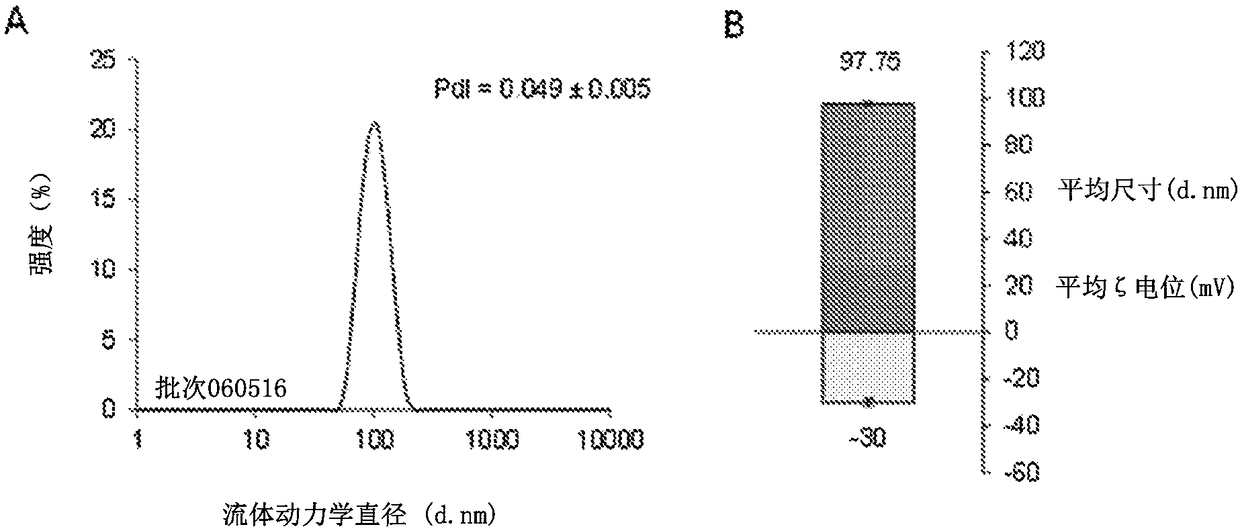

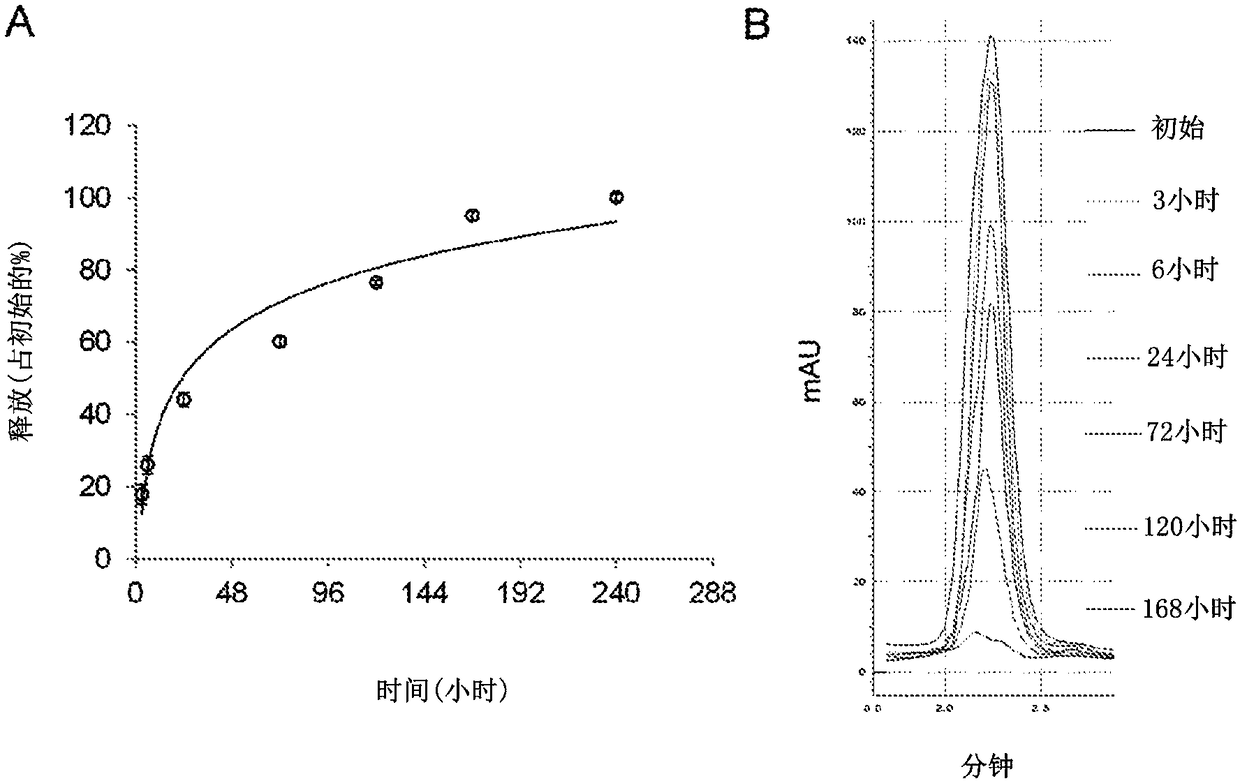

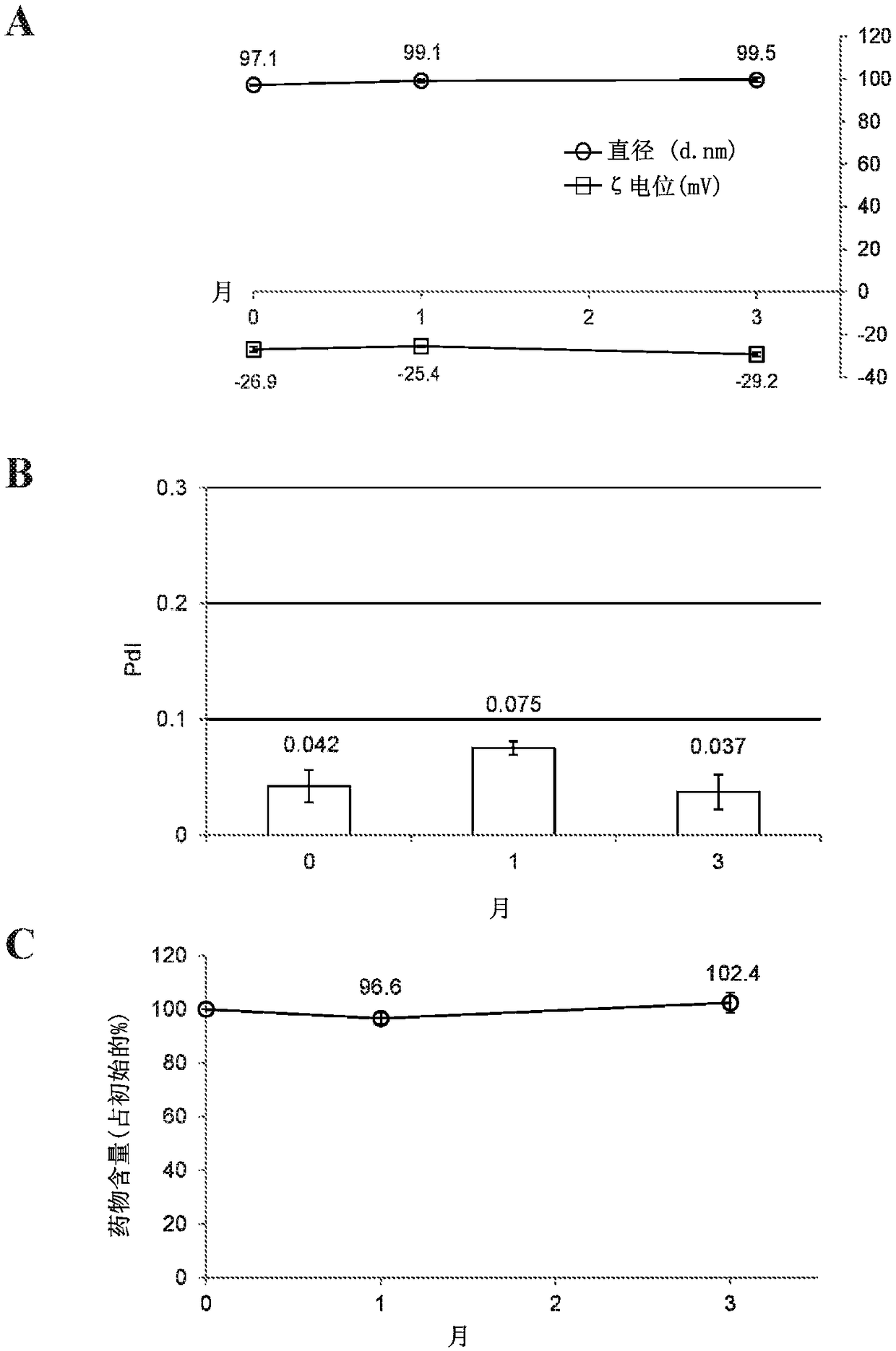

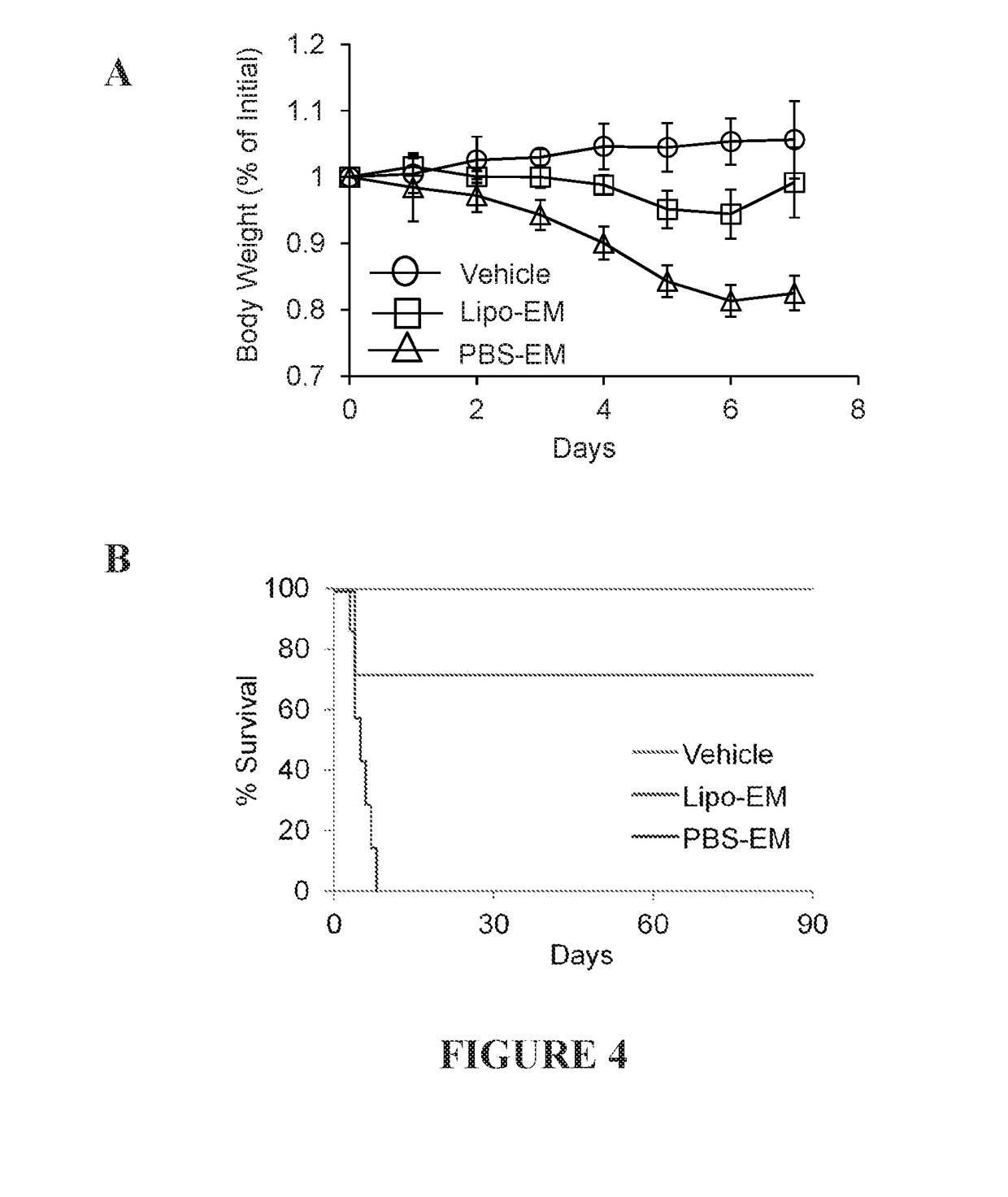

Echinomycin formulation, method of making and method of use thereof

PendingCN108495619AOrganic active ingredientsBacteria material medical ingredientsImmunologic disordersAutoimmune condition

A liposomal drug formulation for treating a disease in a patient characterized by overexpression of HIF-1[alpha] and / or HIF-2[alpha] includes a plurality of liposomes in a pharmaceutically acceptablecarrier. The liposomes encapsulate echinomycin and are made from a peglyated phospholipid, a neutral phosphoglyceride, and a sterol. The PEGylated liposomes may be used to treat proliferative diseases, leukemia, cancer, autoimmune diseases and graft-versus-host disease.

Owner:CHILDRENS RES INST CHILDRENS NAT MEDICAL CENT

Modification of solid 3-sn-phosphoglycerides

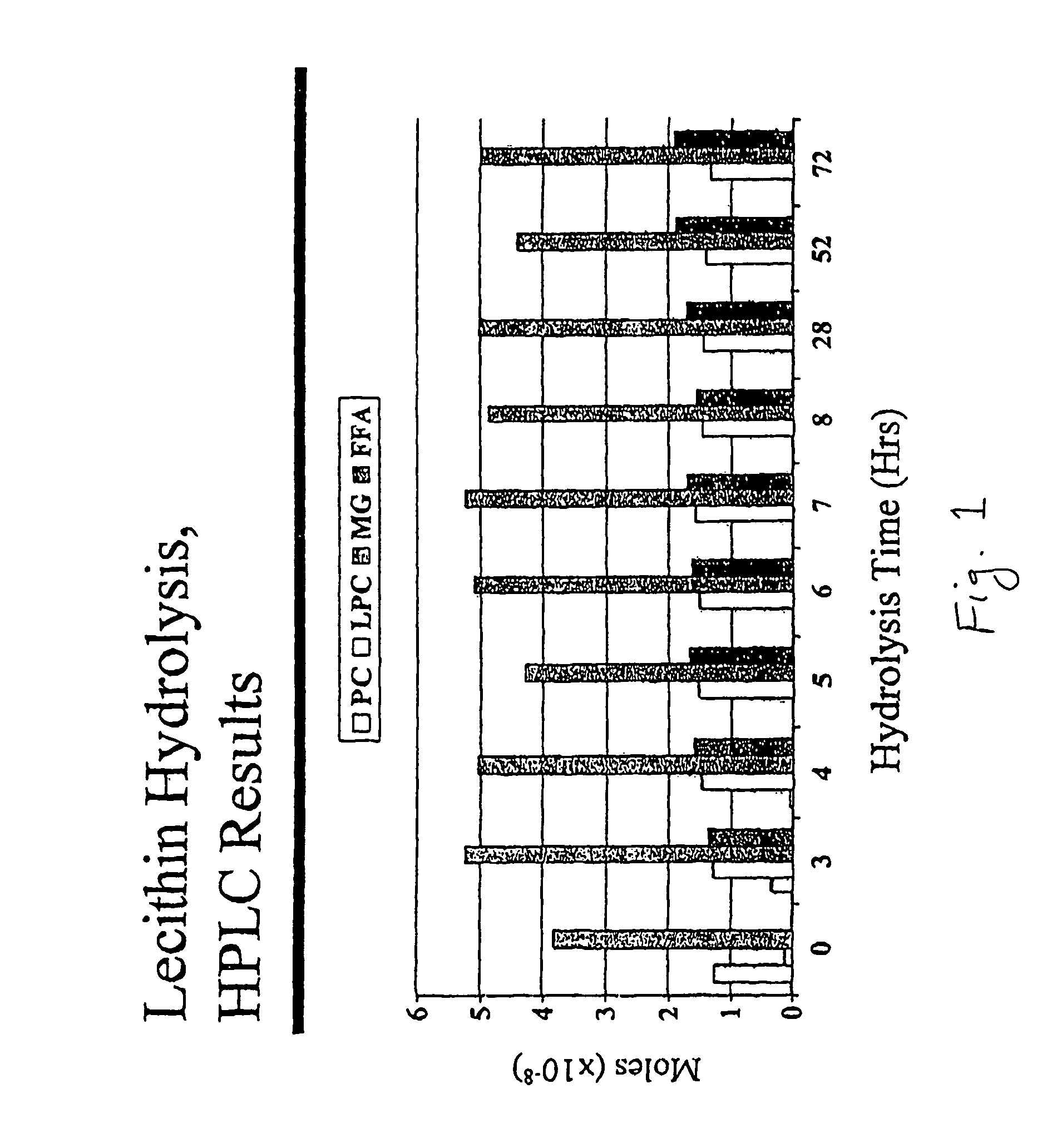

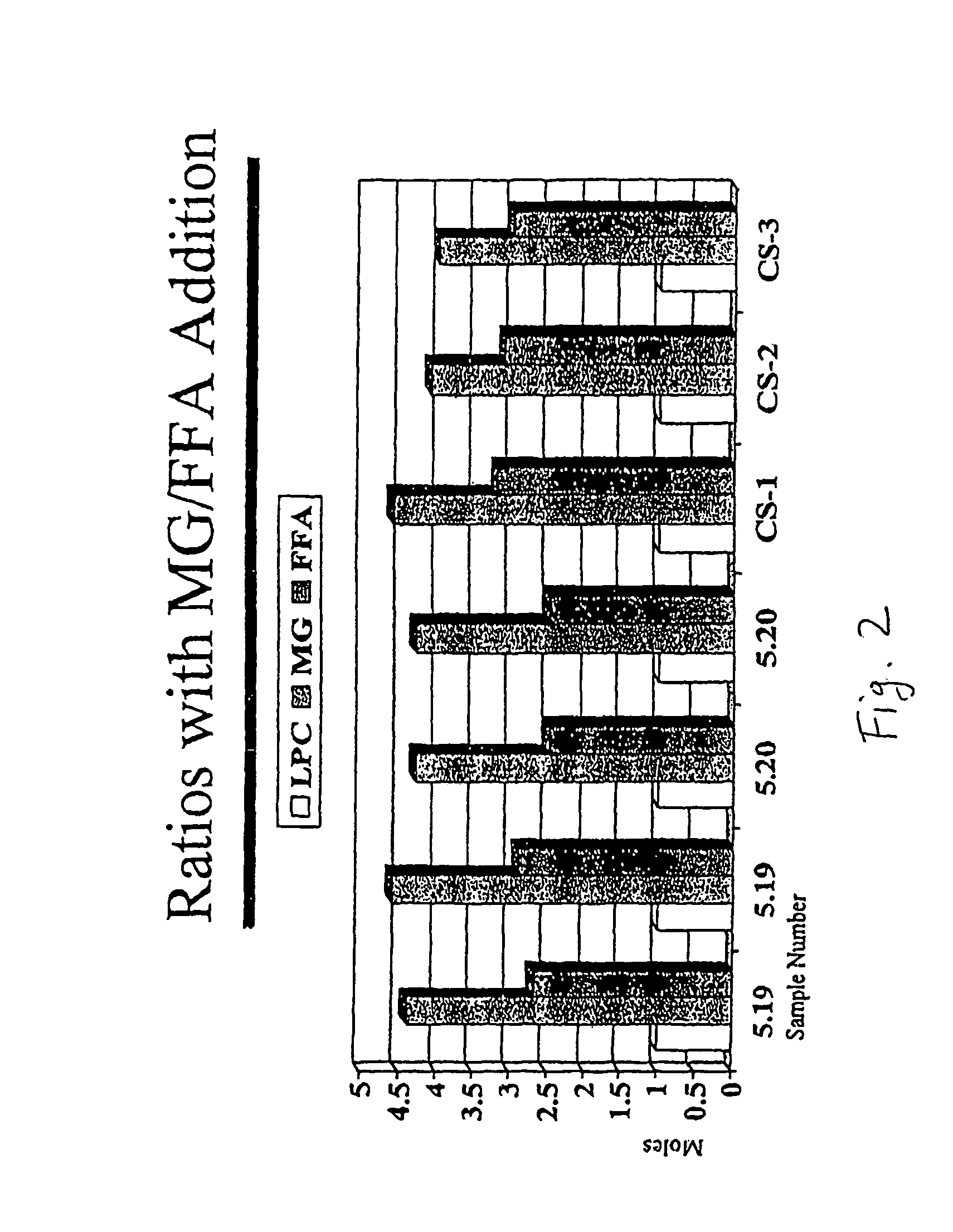

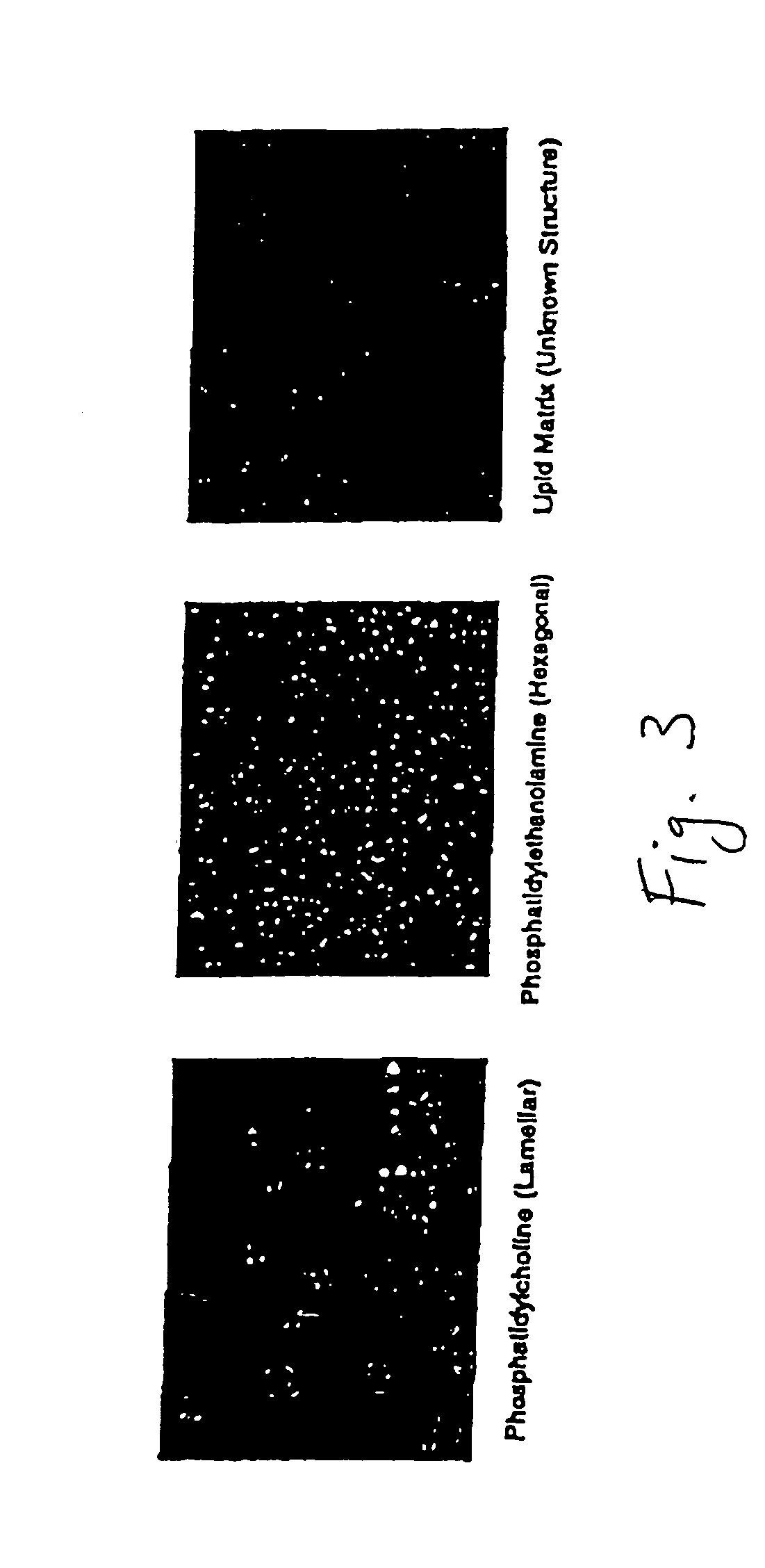

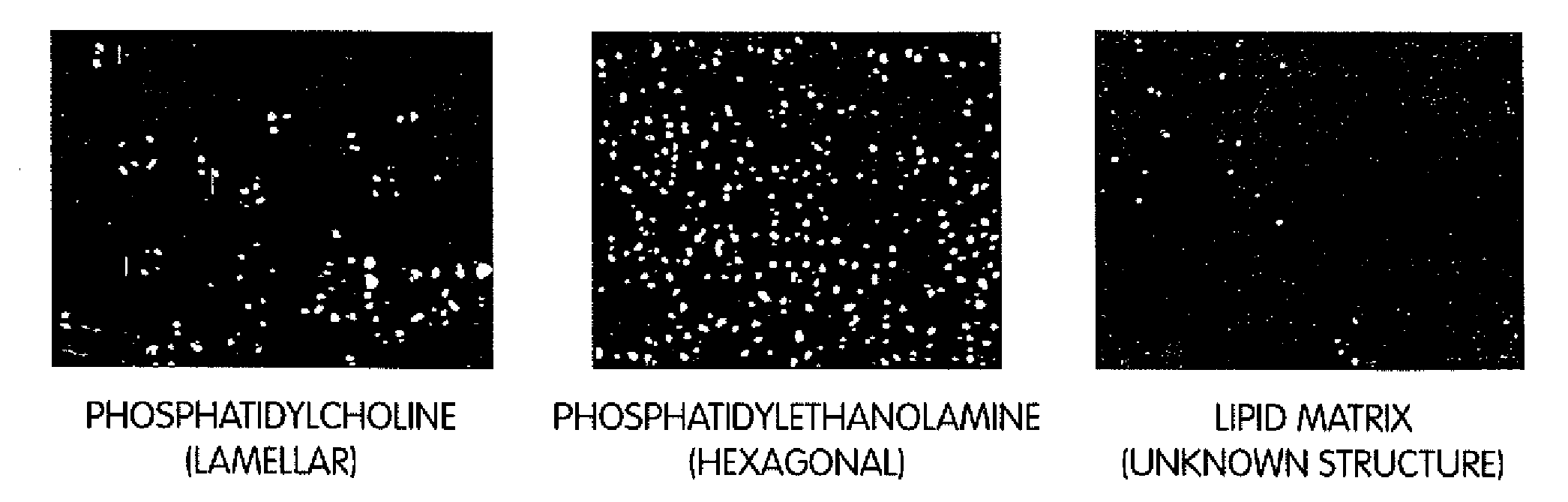

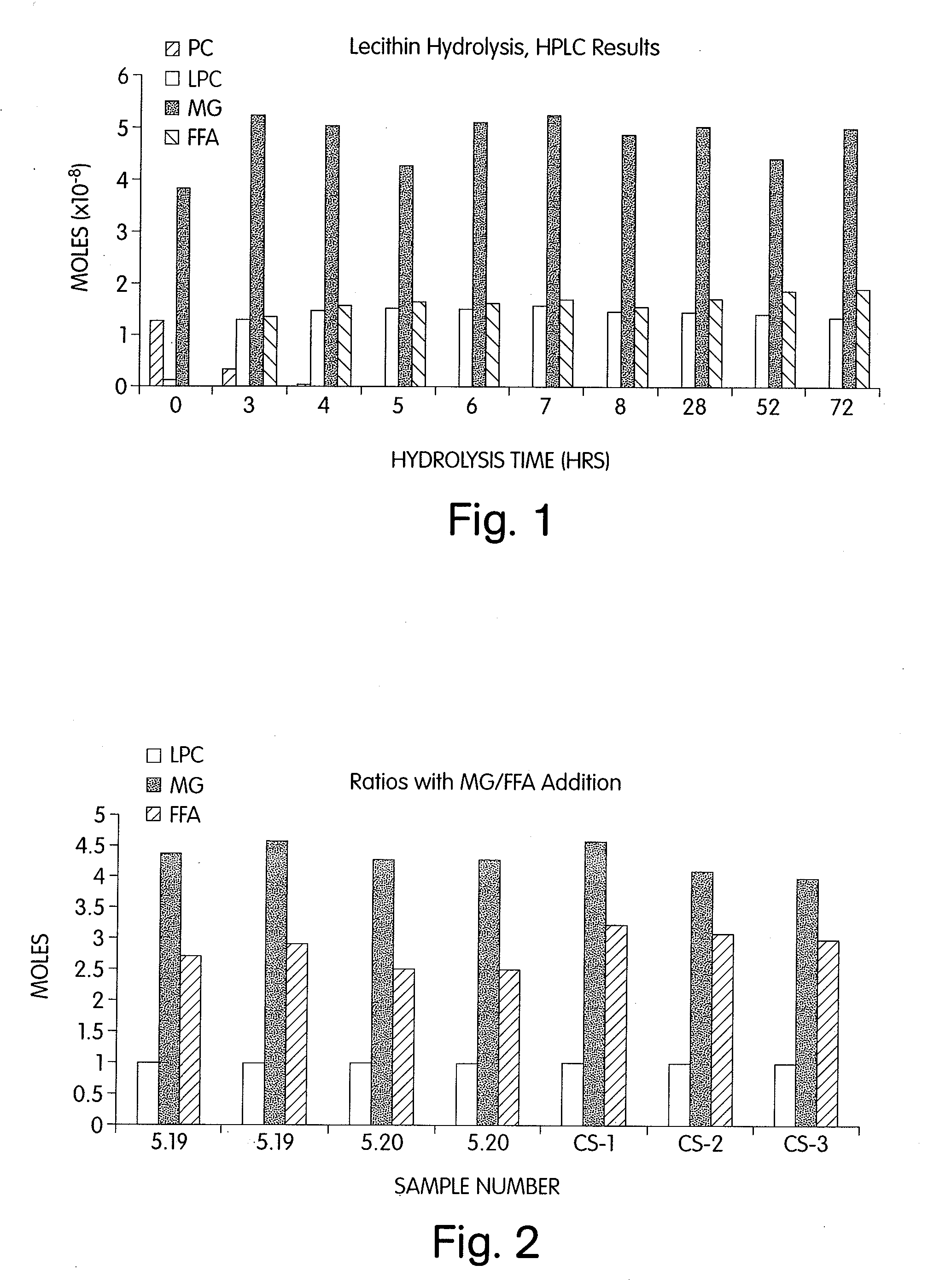

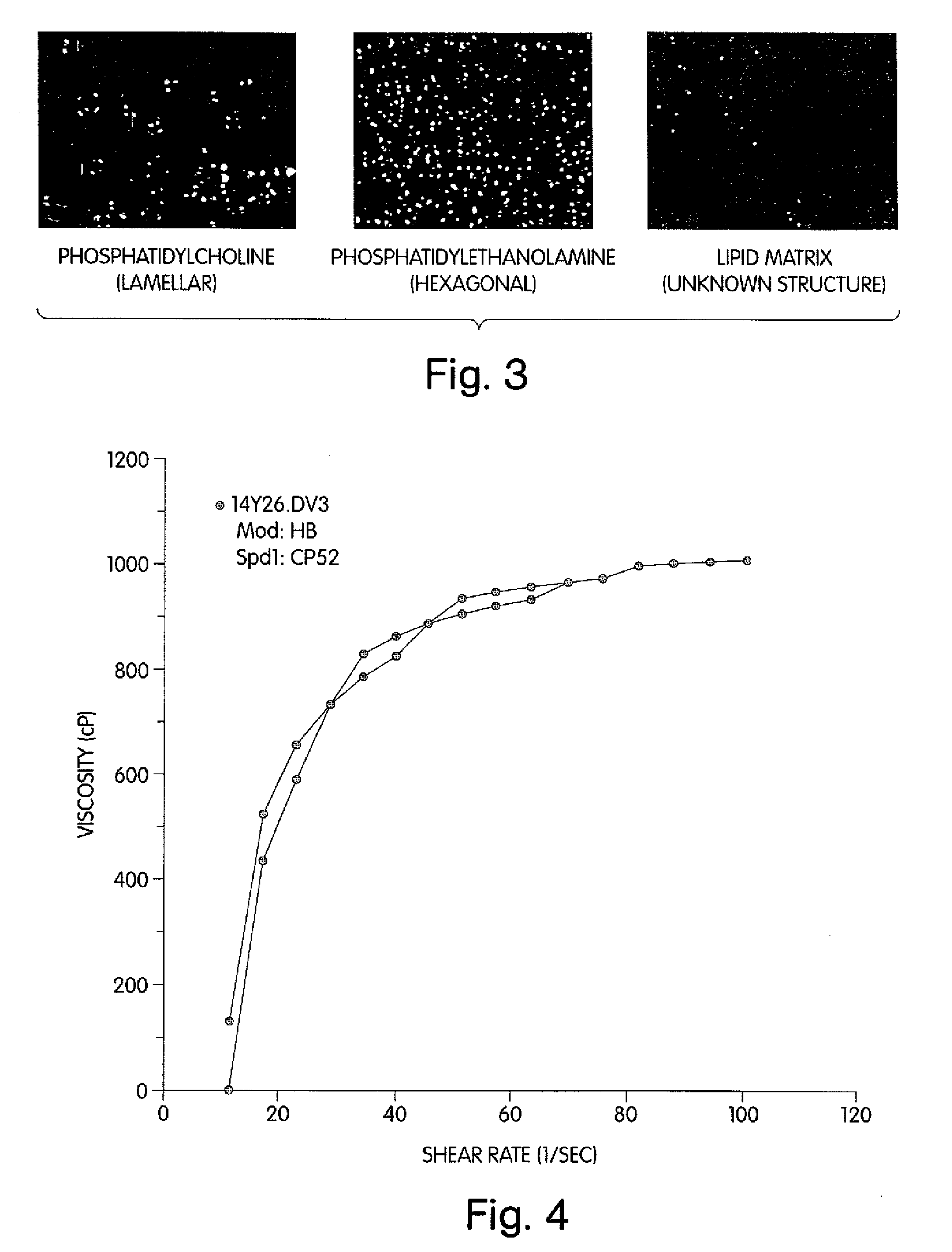

ActiveUS7407779B2Maximum rate of hydrolysisReduce latencyBiocideHydrolasesLipid formationMonoglyceride

Methods for hydrolyzing solid ungranulated lysophosphatidylcholine with phospholipase A2 are provided. Also disclosed are methods for making a lipid matrix of lysophosphatidylcholine, monoglyceride and fatty acid, and lipid matrices of particular structure.

Owner:BIOMOLECULAR PROD

Leather softening agent

ActiveCN104531914AImprove breathabilityExtend your lifePre-tanning chemical treatmentLeather impregnationFiberBULK ACTIVE INGREDIENT

The invention discloses a leather softening agent which is prepared from the following raw materials in parts by weight: 15-35 parts of polyether-modified hydrophilic silicon oil, 10-22 parts of phosphoglyceride, 8-25 parts of sodium dodecyl sulfonate, 40-60 parts of alcohol, 5-15 parts of peregal, 30-50 parts of water and 0-3 parts of lemon essential oil. Active ingredients in the leather softening agent disclosed by the invention can enter the leather very well to form hydrogen bond binding with hydrophilic groups on fibers inside the leather, so that the interwoven or hardened fibers are separated or re-formed into sequenced arrangement, the elastic force of the leather is recovered by increasing gaps among the fibers, and the good gas permeability of the leather is supplemented; the active ingredients are bridged inside the leather, so that the fibers inside the leather and grease are firmly connected and the grease inside the leather is not prone to volatilize, and the service life of the leather is prolonged. The leather treated by the leather softening agent disclosed by the invention has characteristics of good air permeability, softness, rebound resilience and a smooth hand feeling.

Owner:GUANGDONG FION LEATHER CO LTD

Modifications of solid 3-sn-phosphoglycerides

InactiveUS20090017119A1Improvements in enzymatic modification of 3-sn-phosphoglyceride moleculesLow costBiocidePowder deliveryLipid formationMonoglyceride

Owner:BIOMOLECULAR PROD

Inhibition of corrosion in fluid systems

ActiveUS7311877B2Avoid corrosionEffectiveOther chemical processesSpecific water treatment objectivesIndustrial systemsNuclear chemistry

The present invention provides an effective method of inhibiting corrosion on metallic surfaces in contact with a fluid contained in an industrial system, which includes adding to such fluid an effective corrosion controlling amount of a phosphoglyceride compound, optionally with emulsified soybean oil.

Owner:BL TECH INC

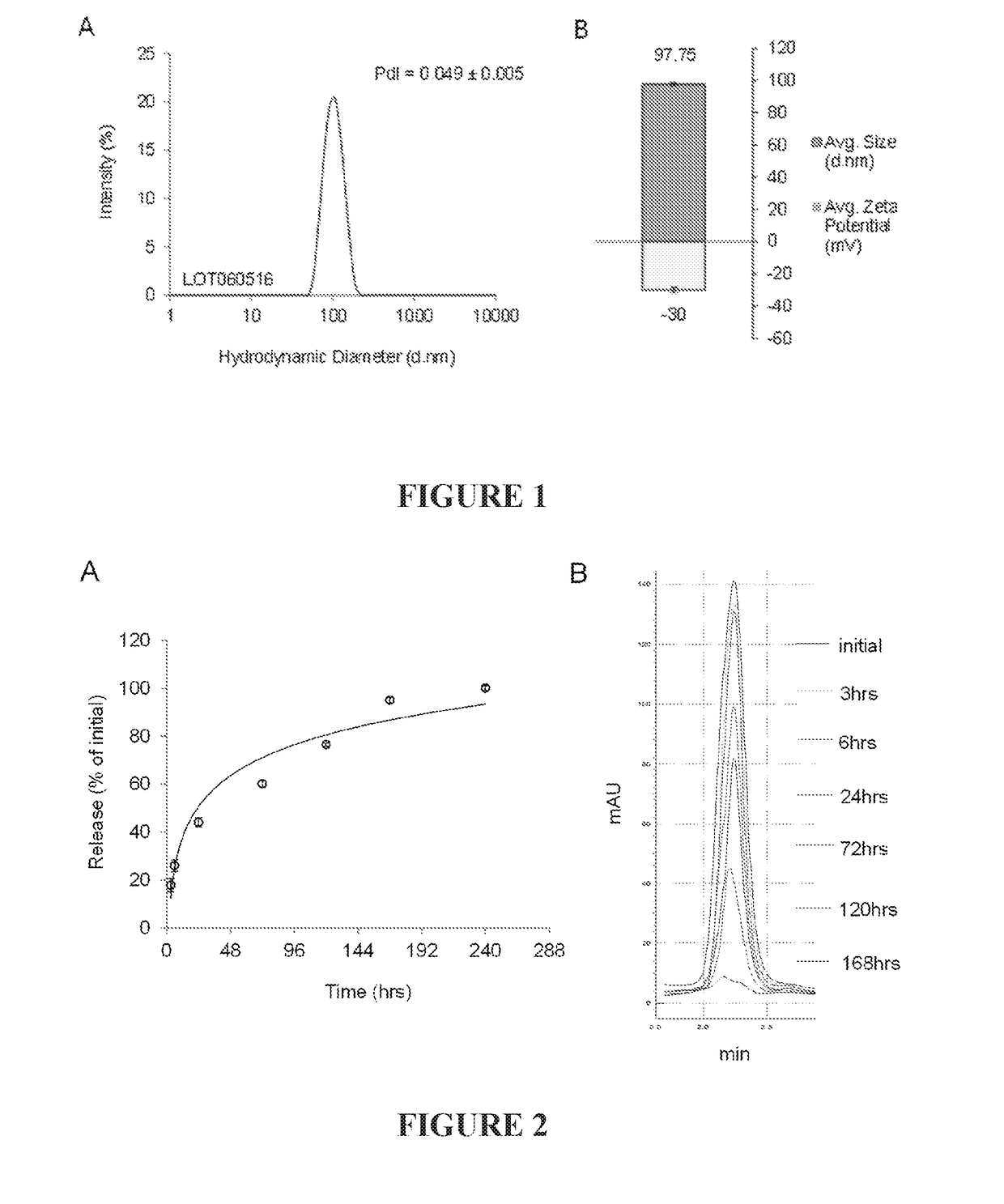

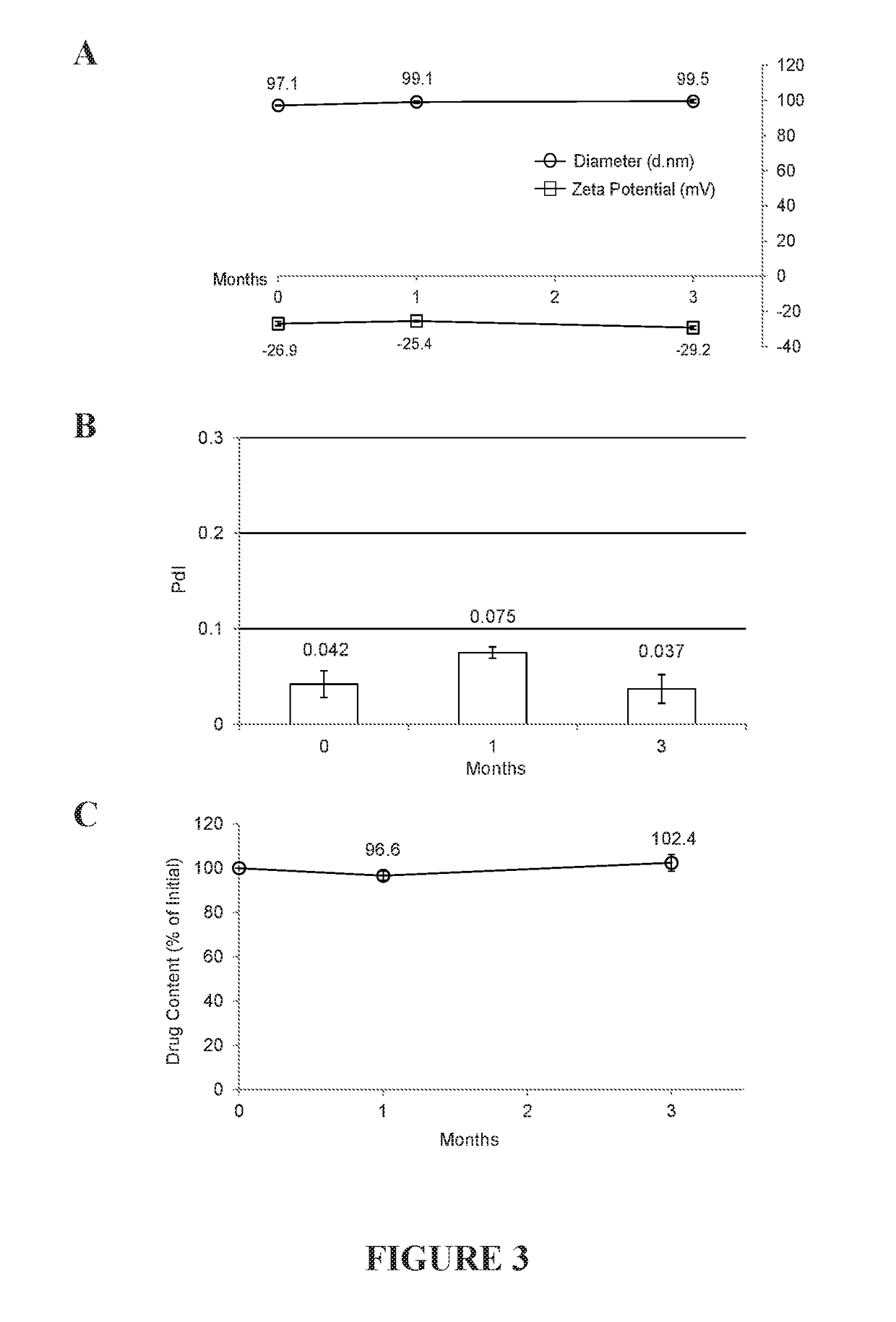

Echinomycin Formulation, Method of Making and Method of Use Thereof

ActiveUS20180344642A1Peptide/protein ingredientsBacteria material medical ingredientsSterolAutoimmune condition

A liposomal drug formulation for treating a disease in a patient characterized by overexpression of HIF-1α and / or HIF-2α includes a plurality of liposomes in a pharmaceutically acceptable carrier. The liposomes encapsulate echinomycin and are made from a peglyated phospholipid, a neutral phosphoglyceride, and a sterol. The PEGylated liposomes may be used to treat proliferative diseases, leukemia, cancer, autoimmune diseases and graft-versus-host disease.

Owner:CHILDRENS RES INST CHILDRENS NAT MEDICAL CENT

Cholinesterase inhibitor preparation method

InactiveCN109694384AShort process stepsMeet the requirements of industrial scale-up productionOrganic chemistry methodsPhosphorus organic compoundsAlcoholCholinesterase

The invention discloses a cholinesterase inhibitor preparation method, and belongs to the technical field of separation and purification of natural medicines. The preparation method comprises: soakinga macroporous cation exchange resin by using an acid solution, completely removing the acid liquid, rinsing with water, soaking with an alkali liquid, rinsing with water, soaking with an acid liquid,rinsing with deionized water, and replacing with lower alcohol; adding glycerol phosphate to the lower alcohol, adding an alkali, carrying out a reaction, carrying out suction filtration, washing with lower alcohol, adjusting the pH value to a weakly alkaline state, carrying out pressure reducing concentrating, cooling, transferring into a separatory funnel, standing, and separating to obtain a lower layer lower alcohol phase; loading glycerol phosphate and a phenol formaldehyde resin onto a column, loading the alcoholysis mixing liquid onto the column, adsorbing, washing the resin with loweralcohol to remove impurities, and eluting the resin with pure water; and decolorizing with a decolorizing agent, and carrying out pressure reducing concentrating to obtain the finished product. According to the present invention, the process steps are short, the requirements of industrial production are met, the resources are saved, the cost is reduced, the total yield of the finished products is65.47-86.08%, the external standard content is over 99%, and the optical purity is 99%.

Owner:张欣

Gray sparkle silver printing ink

The invention relates to a gray sparkle silver printing ink, and belongs to the technical field of printing ink. The gray sparkle silver printing ink comprises 8.5-8.8 wt% of black pigment, 0.53-0.55 wt% of transparent yellow pigment, 0.61-0.65 wt% of transparent blue pigment, 18.0-32.0 wt% of gloss oil, 0.80-1.0 wt% of aluminum powders, 2.2-2.5 wt% of phosphoglyceride compound, 1.2-1.5 wt% of glycerol carbonate allyl ether and residual fine-workmanship T-926 diluent. The gray sparkle silver printing has no stimulation on skin and is green and environmental-friendly, and a good storage stability and good film-forming property are achieved. The gray sparkle silver printing ink applies to printing on PET, PMMA and the surface of glass substrate, a good adhesiveness and abrasive resistance are archived when the printing ink is dried totally, and bleeding phenomenon does not occur basically.

Owner:SUZHOU ANJIE TECH

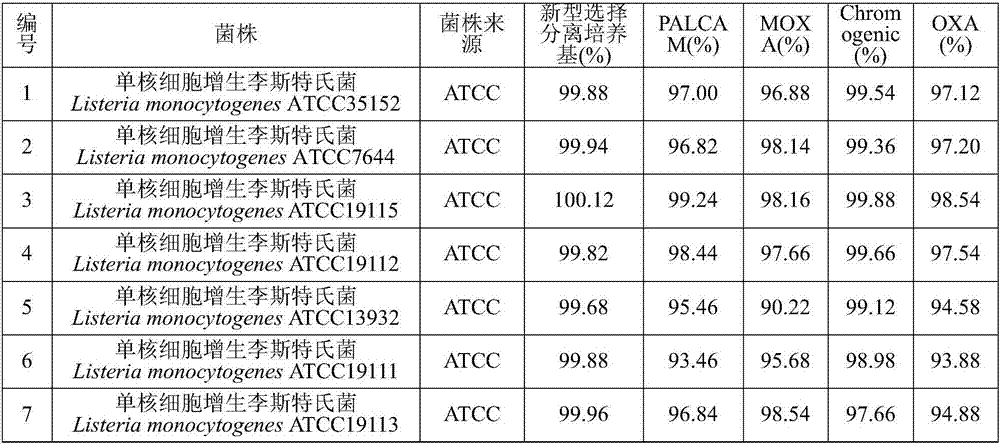

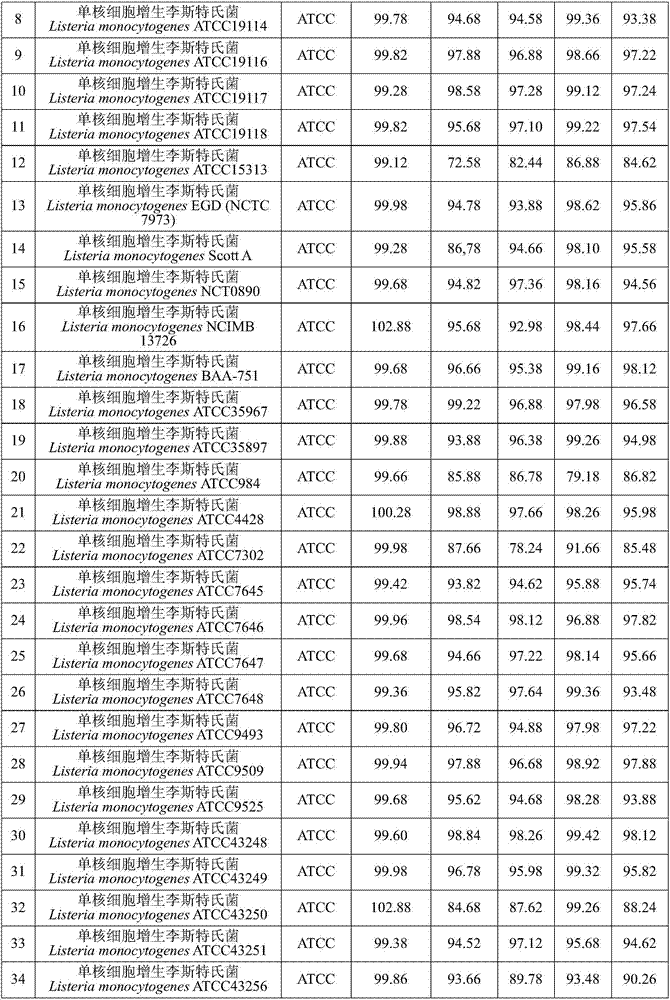

Novel listeriosis selective separating medium, preparation method and application thereof

ActiveCN107385010AGrowth inhibitionPromote growthMicrobiological testing/measurementMicroorganism based processesSodium bicarbonatePropolis

The invention relates to the technical flied of biological examination, and especially relates to a novel listeriosis selective separating medium, a preparation method and an application thereof. A formula of the novel listeriosis selective separating medium comprises 4 g of beef brain infusion powder, 4 g of beef heart infusion powder, 5 g of peptone, 16 g of casein peptone, 5 g of sodium chloride, 2 g of sodium pyruvate, 2 g of glucose, 2.5 g of sodium bicarbonate, 1 g of phosphoglyceride, 12. 5 g of agar powder, 5 ml of a phosphatidylinositol solution with concentration being 0.1 g / ml, 5 ml of a pyrans glucoside solution with concentration being 0.02 g / ml, and 5 ml of a propolis solution with concentration being 0.0125-128.0 [mu]g / ml in each liter of distilled water. The method employs natural antibiosis substance propolis as a selective additive of the listeriosis selective separating medium, an improved basic medium is combined for usage, the background microbe growth in various food can be effectively inhibited, so that the growth of the listeriosis in the selective medium is good, the growth of 13 types of serotype bacterial strains of listeriosis is good, and the pathogenic bacteria can be accurately and sensitively detected in the various food.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-quality, high-efficiency and environment-friendly rabbit skin tanning technology

InactiveCN110564900ANatural colorLight textureTanning treatmentPre-tanning chemical treatmentHair removalSkin treatments

The invention relates to the technical field of rabbit skin treatment and breeding, and in particular relates to a high-quality, high-efficiency and environment-friendly rabbit skin tanning technologywhich comprises the following steps: S1, skin selection and water immersion: selecting rabbit skin without skin and hair damage and hair removal; S2, preparing a softener: weighing an amino acid typesurfactant, polyether modified hydrophilic silicone oil, phosphoglyceride, a preservative, lauryl sodium sulfate, a mildew preventive and the like in parts by weight in proportion, and blending withwater; S3, softening: soaking the rabbit skin in the S1 in the softener until the rabbit skin is completely soaked in the softener; s4, tanning the rabbit skin: adding a tanning agent and water according to the concentration of 5-15g / L, mixing, and soaking the rabbit skin in the mixture; and S5, drying: fishing out the rabbit skin obtained in the step S4, and putting the rabbit skin on a drying rack for drying treatment until the rabbit skin is completely dried, thereby obtaining a finished rabbit skin product. The rabbit skin prepared by the method is softer and softer, and then the rabbit skin is tanned, so that the tanned rabbit skin is natural in color and luster and lighter in texture.

Owner:中梁农业集团股份有限公司

Polyunsaturated fatty acid and fatty acid easter mixture free of sterols and phosphorous compound

InactiveCN1074044CFatty acid esterificationFatty acids production/refiningPhosphoric Acid EstersIodo fatty acid

This invention relates to a process for removing sterols and phosphorous compounds from naturally occurring lipid mixtures. The process involves hydrolyzing a naturally occurring lipid mixture containing phospholipids, triglycerides, and sterols to form a two-phase product containing a fatty acid phase comprised of free fatty acids and sterols, and an aqueous phase comprised of water, glycerol, and glycerol phosphoric acid esters. The aqueous phase is separated from the fatty acid phase and the crude fatty acid phase is heated to convert the free sterols to fatty acid sterol esters. The free fatty acids are distilled from the fatty acid sterol esters to yield purified fatty acids which are free of cholesterol and other sterols, and phosphorous compounds.

Owner:EASTMAN CHEM CO

Production method for glycerol phosphate

InactiveUS20160194673A1Improve efficiencyLow production costHydrolasesFermentationPhosphorylationPhosphoric acid

The present invention addresses the problem of providing a method for the efficient phosphorylation of glycerol. The problem is solved by reacting glycerol with either a kinase that includes the active center expressed by sequence (1) and exhibits a catalytic activity with respect to the phosphorylation of glycerol, or a kinase that includes the amino acid sequence represented by SEQ ID NO: 2 and exhibits a catalytic activity with respect to the phosphorylation of glycerol, in the presence of a phosphate group donor.

Owner:THERMOSTABLE ENZYME LAB

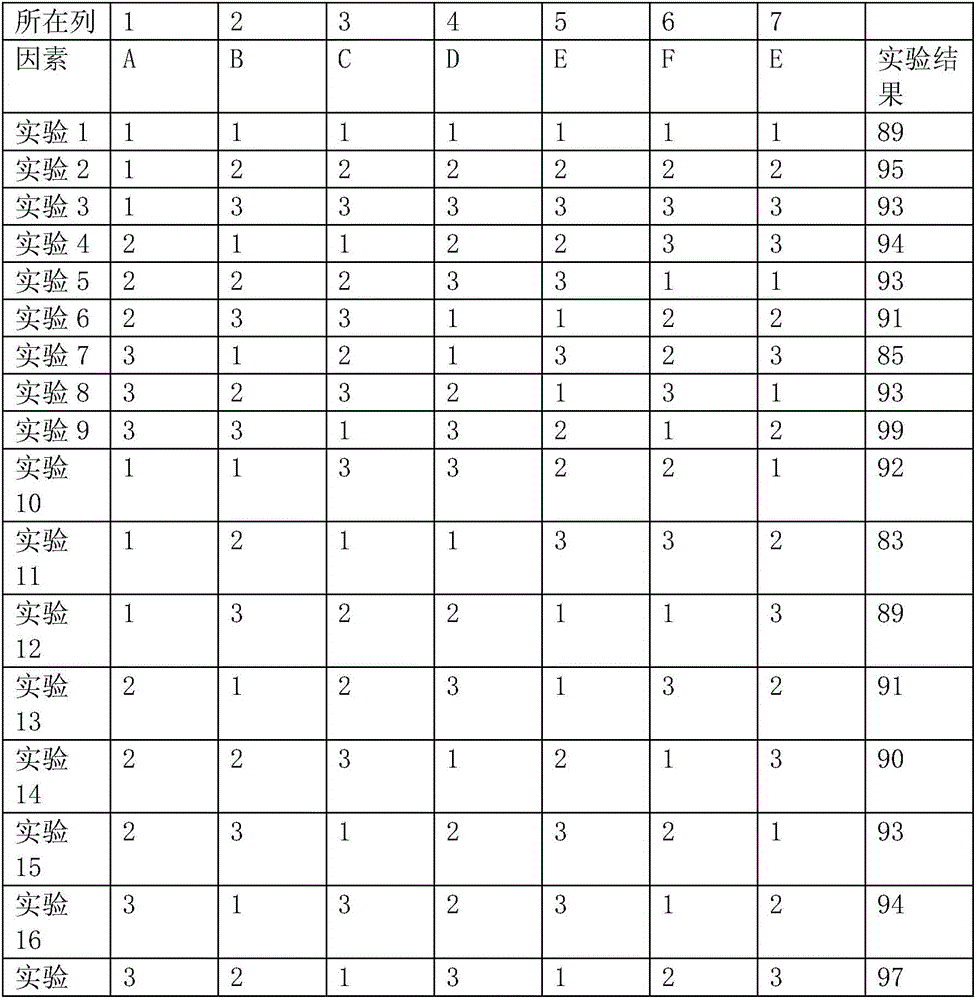

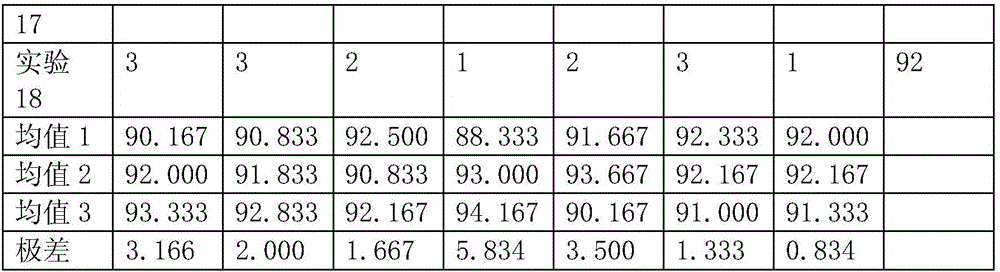

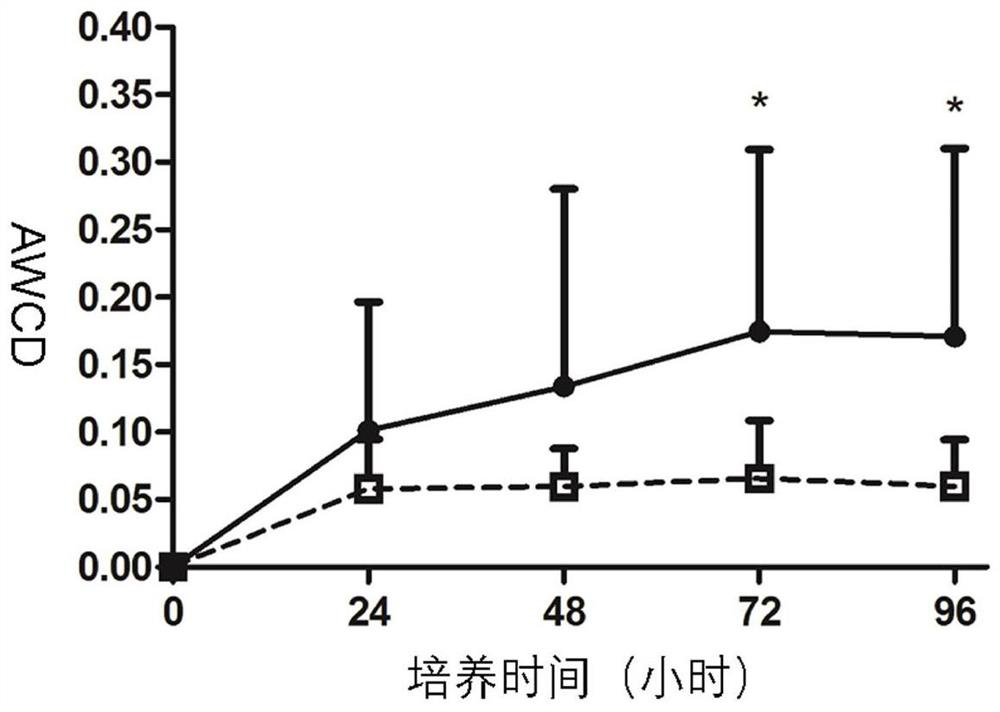

Freeze-drying protective agent used for viral vaccine host and preparation method thereof

InactiveCN105999285AEmulsion stableEasy to useAntiviralsMacromolecular non-active ingredientsFreeze-dryingViral Vaccine

The invention belongs to the technical field of vaccines and particularly relates to a freeze-drying protective agent used for a viral vaccine host and a preparation method thereof. The freeze-drying protective agent used for the viral vaccine host includes chitosan, beta-cyclodextrine, sodium alginate, raffinose, lactic acid, inositol phosphoglyceride and butyl hydroxy anisd. The freeze-drying protective agent used for the viral vaccine host is designed for the host, and reasonable synergistic combination is conducted by researching and exploring matter having a protective function on cells. Host cell preservation conditions are optimized by means of the freeze-drying protective agent, and a foundation is laid for better virus preservation.

Owner:吴忆春 +2

Preparation method of anti-respiratory-system-virosis fiber

InactiveCN111074572AAchieve protectionAchieve therapeutic effectBiochemical fibre treatmentFibre typesPolyethylene terephthalate glycolActive agent

The invention provides a preparation method of an anti-respiratory-system-virosis fiber. According to the fiber, polyethylene terephthalate (PET) is used as a substrate, exogenous pulmonary surfactantis used, by surface modifying long-chain phospholipid molecules, and glycerol phosphate, acidic phospholipids and a pulmonary surfactant antiviral drug composed of specific proteins are further adsorbed. The protection and treatment of respiratory system virosis are realized. The fiber can be used to prepare products such as protective masks, wherein exogenous pulmonary surfactant are loaded on the surface of the fiber by means of adsorption and can enter a body through breathing to play an antiviral effect. The preparation method is simple in preparation procss, the reaction is easy to control, the stability is good, and the preparation method can be industrialized and has a broad promotion prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

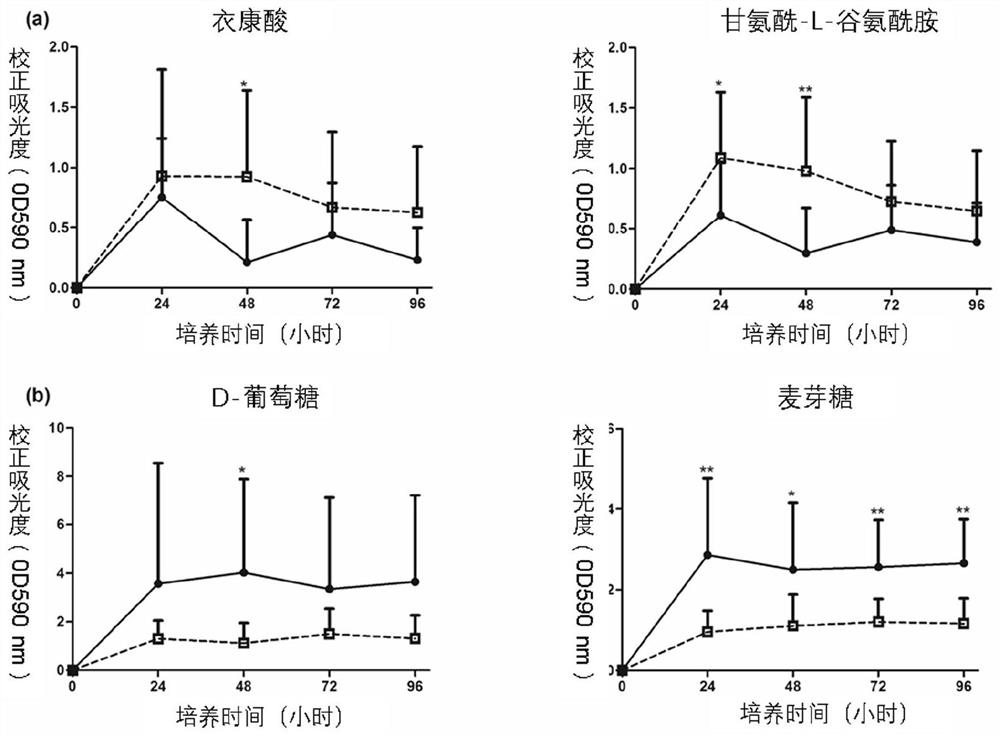

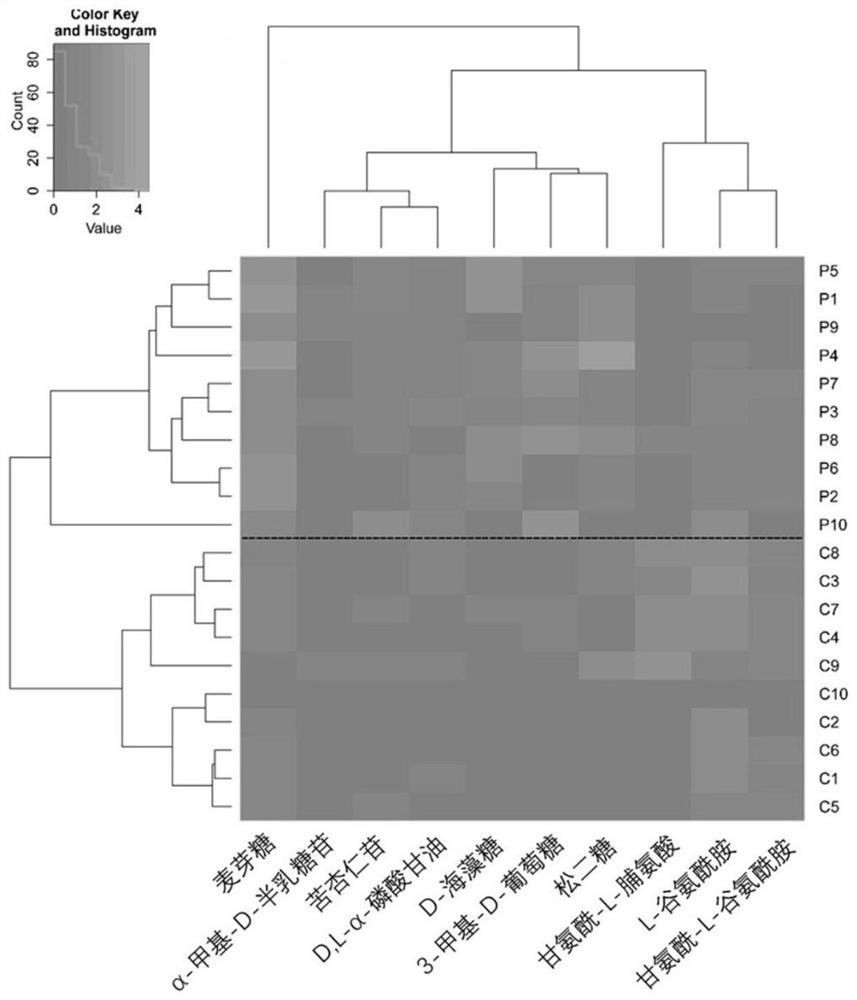

A kit for predicting whether children are susceptible to dental caries

ActiveCN108120679BEasy to usePredicting the Risk of CariesMaterial analysis by observing effect on chemical indicatorGlycyl glutamineTyrosine

The invention relates to a kit for predicting dental caries susceptibility of children. The kit contains maltose, alpha-methyl-D-galactoside, alpha-amygdalin, D,L-alpha-phosphoglyceride, D-trehalose,3-methyl-D-glucose, turanose, glycyl-L-tyrosine-L-proline, L-glutamine and glycyl-L-tyrosine-L-glutamine, wherein the components are 10 carbon sources in all for predicting the risk of dental caries of children. The kit can be used in medical institutions or even families, and the illness risk can be predicted before children have dental caries, so that dental caries can be prevented in advance, and society resources for dental caries can be greatly reduced.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

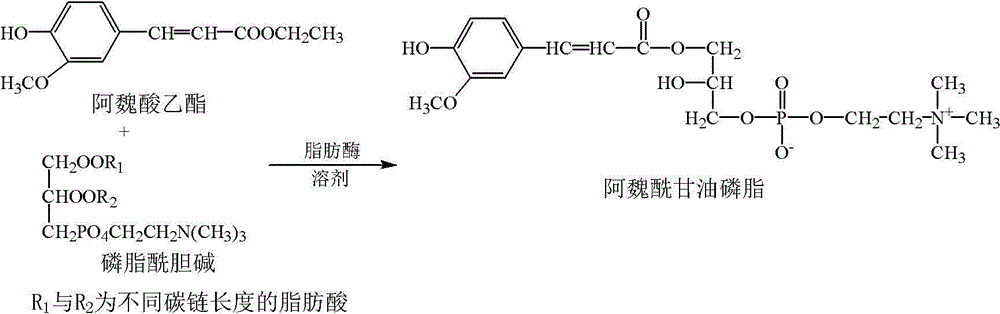

Enzymatic synthesis method of ferulic acid phosphoglyceride

InactiveCN102943095AGood structural unityEasy to operateFermentationEnzymatic synthesisMolecular sieve

The invention relates to an enzymatic synthesis method of ferulic acid phosphoglyceride. The method is characterized by including adding an activated molecular sieve to an organic solvent for dehydration process for 24-96h to obtain the dehydrated organic solvent; enzymatic esterification reaction: adding hydrolyzed phospholipid and ferulic acid ethyl ester to the dehydrated organic solvent according to the mole ratio of 8:1 to 1:8, adding an enzyme and the activated molecular sieve, and shaking at a temperature of 40-70 DEG C for 10-240h; and filtering after reaction, performing rotary evaporation on the clarified filtrate to remove the organic solvent to obtain the ferulic acid phosphoglyceride with a conversion rate up to 40%. According to the method, the operation is simple, the method is environment-friendly, the catalyst and the enzyme can be recycled, and the obtained product is good in structural unicity.

Owner:DALIAN UNIV OF TECH

Preparation method of grey flash silver ink

The invention relates to a preparation method of grey flash silver ink and belongs to the technical field of printing ink. The grey flash silver ink comprises black pigment, transparent yellow pigment, transparent blue pigment, gloss oil, silver powder, phosphoglyceride compound, glycerol carbonate allyl ether and the balance of Seiko T-926 diluent. The preparation method includes mixing and grinding. The preparation method has the advantages that the prepared grey flash silver ink is free of stimulation to the skin, environmental friendly, good in storage stability, good in film forming property and applicable to the printing of the surfaces of PET, PMMA and glass base material, and the ink is good in attaching performance, good in wear resistance and basically free of exudation after being completely dried.

Owner:SUZHOU ANJIE TECH

Preparation technology of DNA (DesoxyriboNucleic Acid) for treating pneumonia

InactiveCN109810151AShort process stepsMeet the requirements of industrial scale-up productionSugar derivativesSugar derivatives preparationAlcoholFiltration

The invention discloses a preparation technology of DNA (DesoxyriboNucleic Acid) for treating pneumonia and belongs to the technical field of separation purification of natural drugs. The preparationtechnology comprises the following steps: soaking macroporous cation exchange resin with acid fluid, completely draining the acid fluid and flushing with water; then soaking with lye and flushing withthe water; then soaking the macroporous cation exchange resin with the acid fluid again, flushing with deionized water and replacing with low carbon alcohol; adding phosphoglyceride into the low carbon alcohol, adding alkali for reacting, carrying out suction filtration, washing with the low carbon alcohol, and adjusting the pH to weak basicity, carrying out vacuum concentration, cooling, transferring to a separating funnel, standing and separating out a lower low carbon alcohol phase; loading the phosphoglyceride and phenolic resin on a column, carrying out column adsorption on alcoholysis mixed liquid, washing the resin with the low carbon alcohol, purifying and eluting the resin with pure water; decolorating by using a decoloring agent and carrying out vacuum concentration to obtain afinished product. The preparation technology has the advantages that technological steps are short and the requirements of industrial production are met; resources are saved and the cost is reduced; the total yield of a finished product reaches 65.47 to 86.08 percent, the external standard content reaches 99 percent or above and the optical purity reaches 99 percent.

Owner:孔祥圣

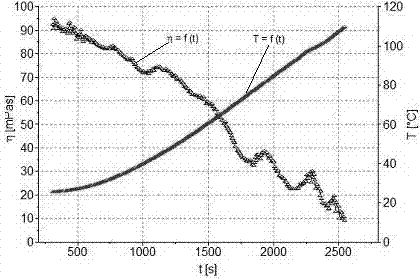

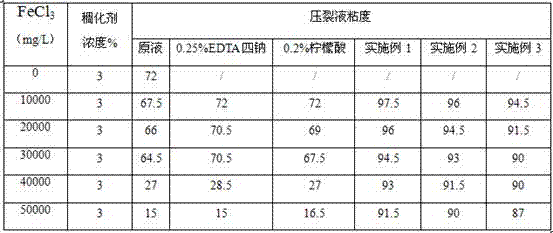

Biological regulator for fracturing, and preparation method and application thereof

InactiveCN107573919ALittle impact on performanceImprove temperature resistanceDrilling compositionFracturing fluidSodium citrate

The invention provides a biological regulator for fracturing, and a preparation method and application thereof. The biological regulator comprises the following substances in percentage by weight: 8-15% of sodium citrate dihydrate, 3-6% of iron ion stabilizer, 21-32% of p-toluenesulfonic acid, 3-7% of phosphoglyceride, 2-12% of ethanol and the balance of water. The biological regulator can effectively shield high-valence (bivalent and trivalent) ions in fluid preparation water or a flow-back fluid, can reduce the influence on the performance of a prepared fracturing fluid, and can improve thetemperature tolerance of the fracturing fluid; the sodium citrate dihydrate in the regulator can regulate the pH value; and the regulator is biodegradable, nontoxic and harmless, and ensures the greenenvironment-friendly production and sustainable development of oilfields.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

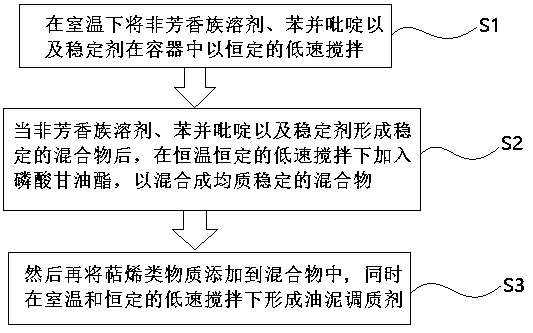

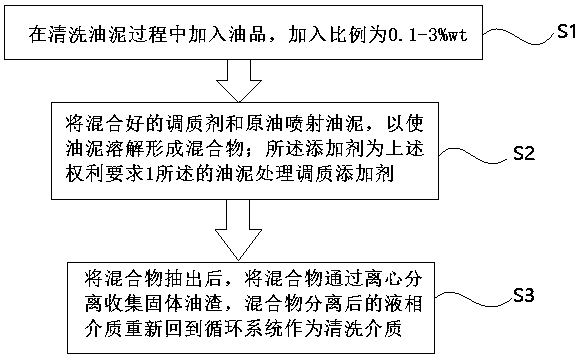

Oil sludge treatment conditioning additive, preparation method and use method thereof

InactiveCN111363579AEasy to separateEmission reductionLiquid hydrocarbon mixture productionSludge treatment with immiscible liquidsAromatic solventInorganic particle

The invention relates to an oil sludge treatment conditioning additive, a preparation method and a use method thereof, wherein the additive comprises the following components in percentage by weight:60-90 wt% of a non-aromatic solvent, 5-15 wt% of phosphoglyceride, 5-15 wt% of a terpene substance, 5-15 wt% of benzopyridine, and 0.5-1 wt% of a stabilizer. According to the scheme provided by the invention, the influence of asphaltene on inorganic particles can be reduced, a good separation effect of the inorganic particles in an oil product in a centrifugal process is realized, and the discharge of solid wastes is reduced; and the conditioning additive does not depend on an aromatic solvent, the traditional dilution method is changed, the separation effect can be improved by using a small amount of the conditioning additive, and the conditioning additive is environment-friendly.

Owner:北京蓝星清洗有限公司

Preparation method of phosphatidyl glycerol inhibitor

InactiveCN109776603AShort process stepsMeet the requirements of industrial scale-up productionPhosphatide foodstuff compositionsOn columnAlcohol

The invention relates to a preparation method of a phosphatidyl glycerol inhibitor, belonging to the technical field of separation and purification of natural medicines. The method comprises the following steps: firstly, soaking macroporous cation exchange resin in an acid solution, draining the acid solution, and rinsing with water; then, soaking in an alkali solution, and rinsing with water; then, soaking in the acid solution, rinsing with deionized water, and then using lower alcohol for replacing; adding glycerol phosphate into the lower alcohol, adding alkali for carrying out a reaction,and then performing suction filtration; washing with the low alcohol, adjusting pH to be weakly alkaline, concentrating under reduced pressure and cooling, then transferring into a separating funnel,standing, and separating out a lower layer lower alcohol phase; packing the glycerol phosphate and phenolic resin in a column, carrying out on-column absorption on alcoholysis mixed liquid, washing the resin with the lower alcohol for removing impurities, and eluting the resin with pure water; carrying out decolorization by using a decolorizing agent, and concentrating under reduced pressure to obtain the finished product. The preparation method has the advantages that the technological steps are simple and short, and the requirements of industrial production are met; the resources are saved,and the cost is lowered; the total yield of the finished product reaches 65.47-86.08%, the external standard content reaches 99% or above, and the optical purity reaches 99%.

Owner:陕西卓力时代人力资源有限公司

Toilet cleaning agent

InactiveCN106398889ALow costNon-ionic surface-active compoundsDetergent compounding agentsGlycerolSodium dodecylbenzenesulfonate

The present invention discloses a toilet cleaning agent, which comprises the following raw materials by weight: 20-26% of sodium dodecylbenzenesulfonate, 12-20% of phosphoglyceride, 3-9% of phosphoamide, 1-4% of glycerol, 0.4-0.8% of sodium hydroxide, 0.1-0.5% of melamine, 0.04-0.08% of pigment, and the balance of water.

Owner:李尧

Novel glycerol phosphatidylcholine preparation method

InactiveCN109694385AShort process stepsMeet the requirements of industrial scale-up productionOrganic chemistry methodsPhosphorus organic compoundsAlcoholFiltration

The invention discloses a novel glycerol phosphatidylcholine preparation method, and belongs to the technical field of separation and purification of natural medicines. The preparation method comprises: soaking a macroporous cation exchange resin by using an acid solution, completely removing the acid liquid, rinsing with water, soaking with an alkali liquid, rinsing with water, soaking with an acid liquid, rinsing with deionized water, and replacing with lower alcohol; adding glycerol phosphate to the lower alcohol, adding an alkali, carrying out a reaction, carrying out suction filtration, washing with lower alcohol, adjusting the pH value to a weakly alkaline state, carrying out pressure reducing concentrating, cooling, transferring into a separatory funnel, standing, and separating toobtain a lower layer lower alcohol phase; loading glycerol phosphate and a phenol formaldehyde resin onto a column, loading the alcoholysis mixing liquid onto the column, adsorbing, washing the resinwith lower alcohol to remove impurities, and eluting the resin with pure water; and decolorizing with a decolorizing agent, and carrying out pressure reducing concentrating to obtain the finished product. According to the present invention, the process steps are short, the requirements of industrial production are met, the resources are saved, the cost is reduced, the total yield of the finished products is 65.47-86.08%, the external standard content is over 99%, and the optical purity is 99%.

Owner:张欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com