Patents

Literature

30results about How to "Improve the adhesion firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance recycled concrete and preparation process thereof

ActiveCN110540389AImprove work performanceImprove compactnessBuilding material handlingWork performanceChipseal

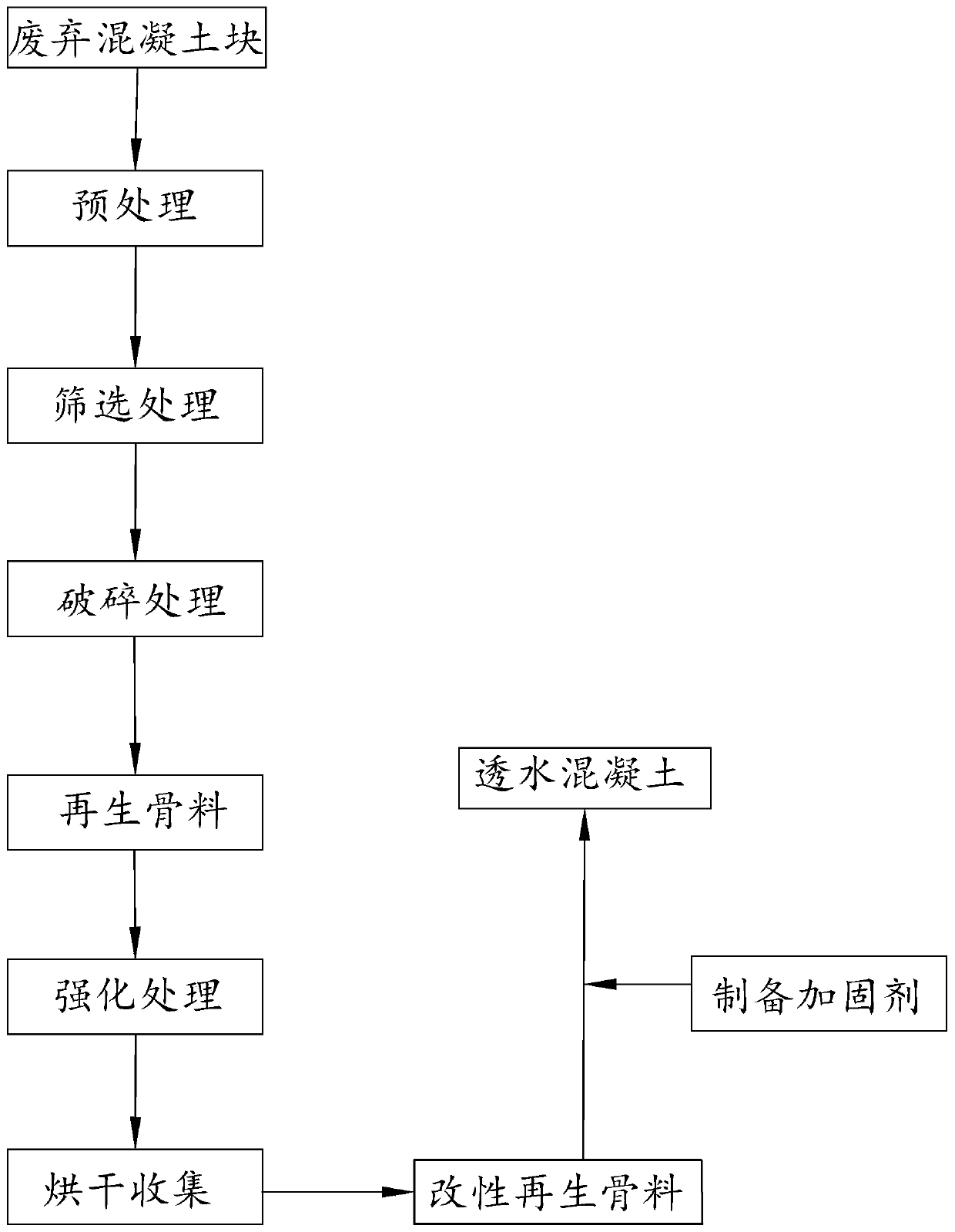

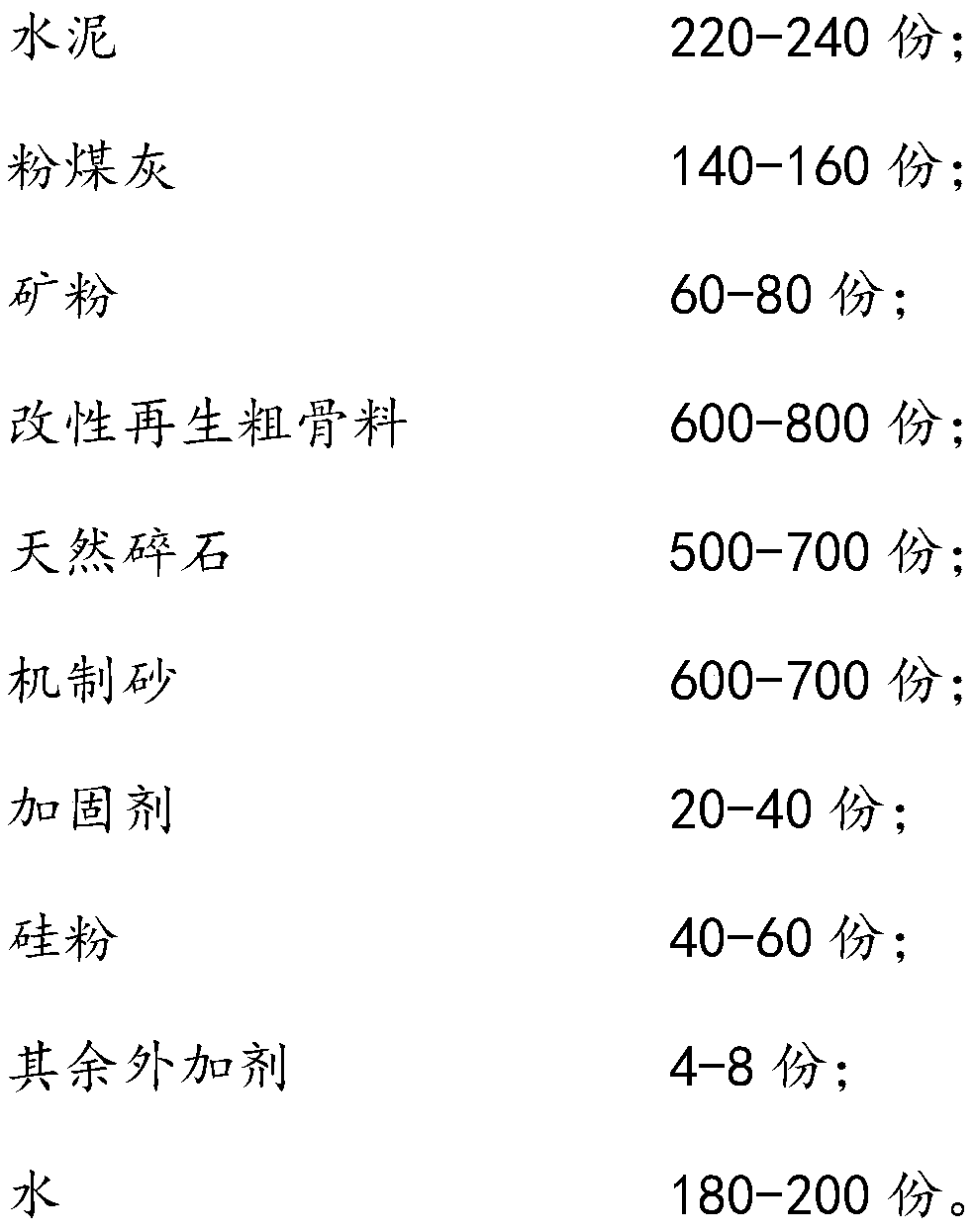

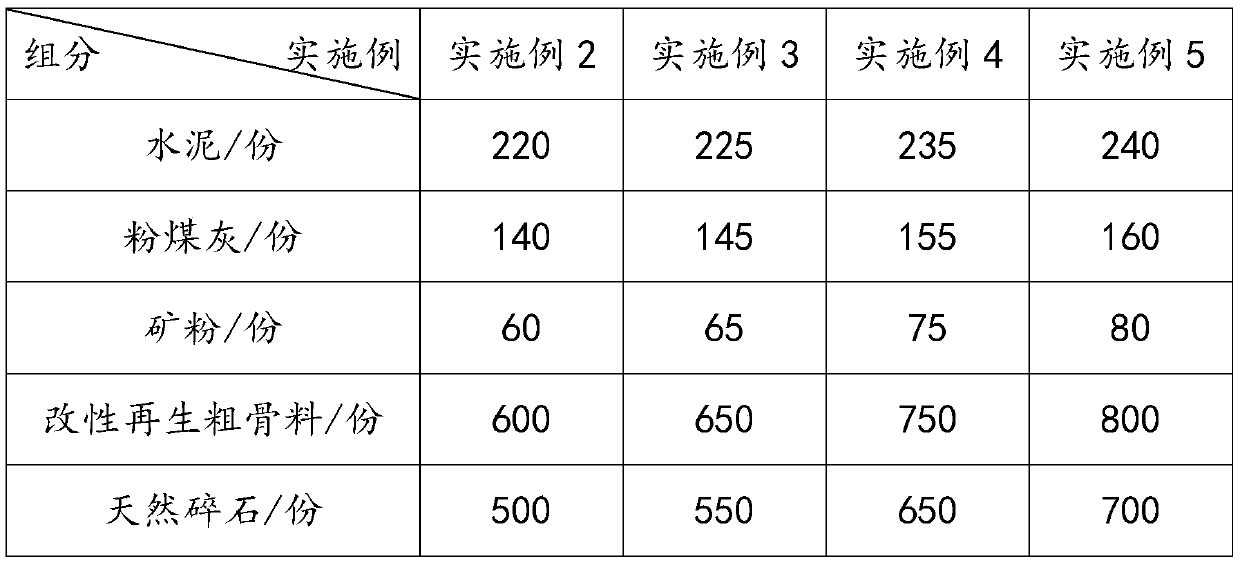

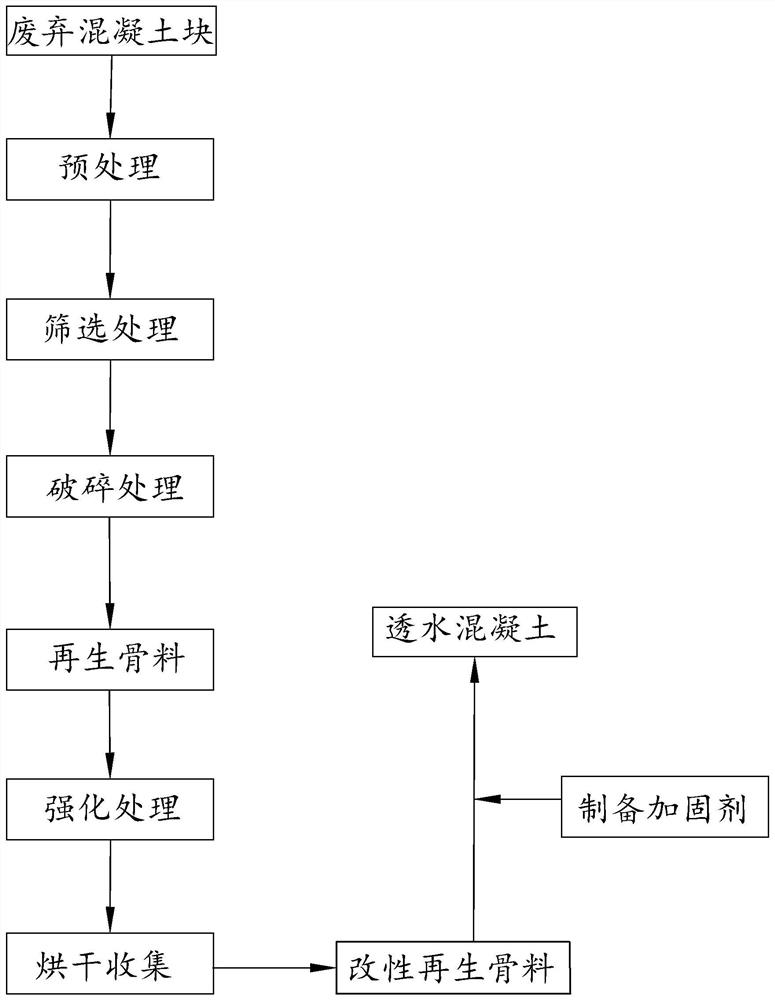

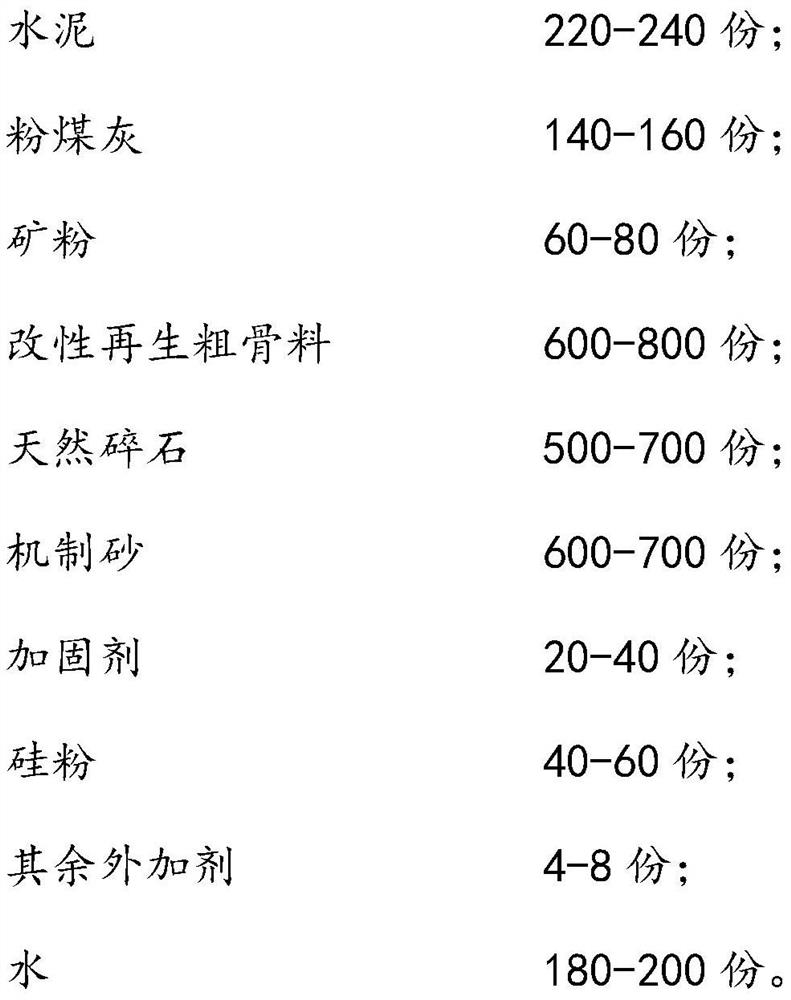

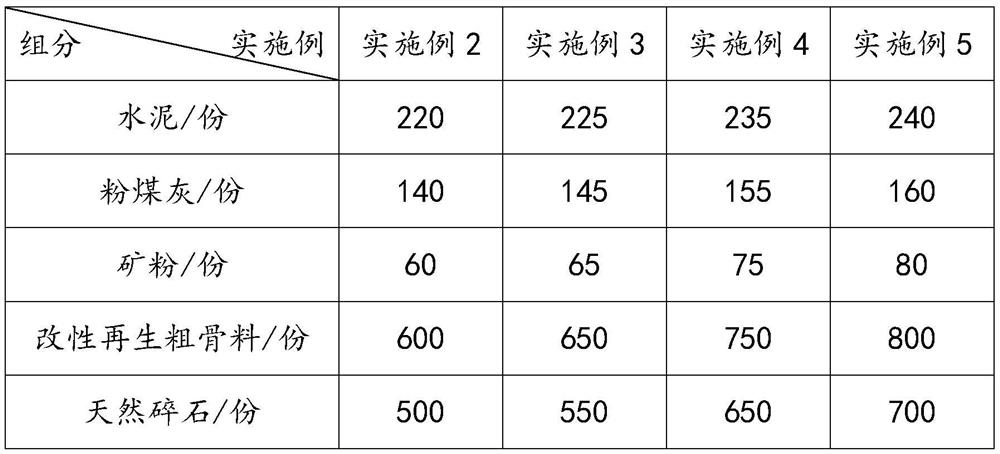

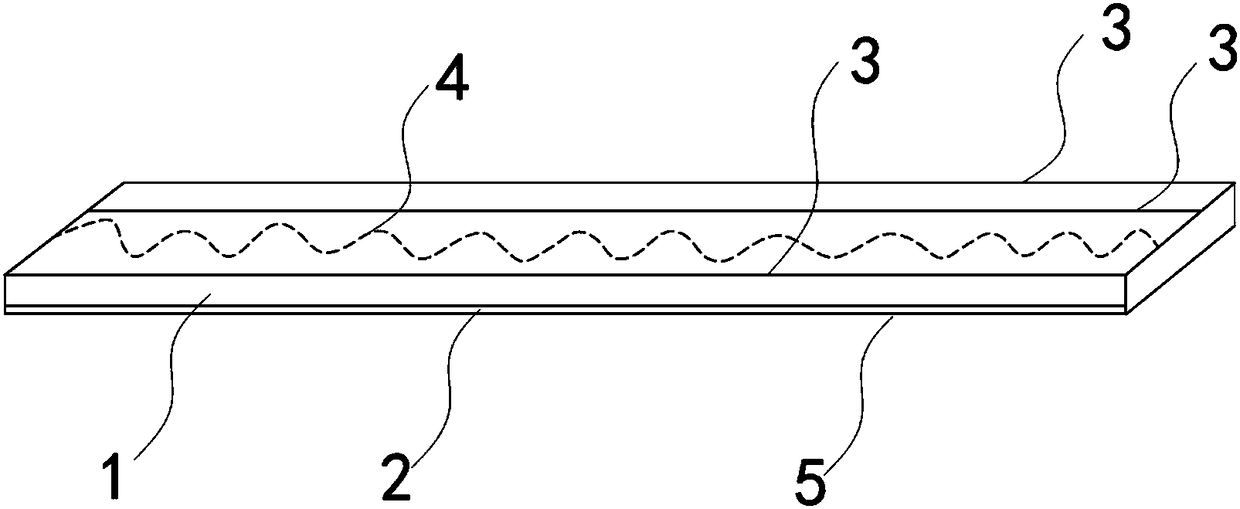

The invention discloses high-performance recycled concrete and a preparation process thereof, and relates to the technical field of concrete preparation. The concrete includes the following raw materials in parts by weight: 220-240 parts of cement; 140-160 parts of fly ash; 60-80 parts of mineral powder; 600-800 parts of modified recycled coarse aggregate; 500-700 parts of natural gravel; 600-700parts of machined sand; 20-40 parts of a reinforcing agent; 40-60 parts of silicon powder; 4-8 parts of other additives; and 180-200 parts of water. By adjusting the ratio of the various raw materialsof the concrete, adding the reinforcing agent and modifying the recycled aggregate, the working performance of the concrete can be effectively improved, and the compactness and overall strength of the concrete can be improved.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

Modified fiber product, preparation method and applications thereof

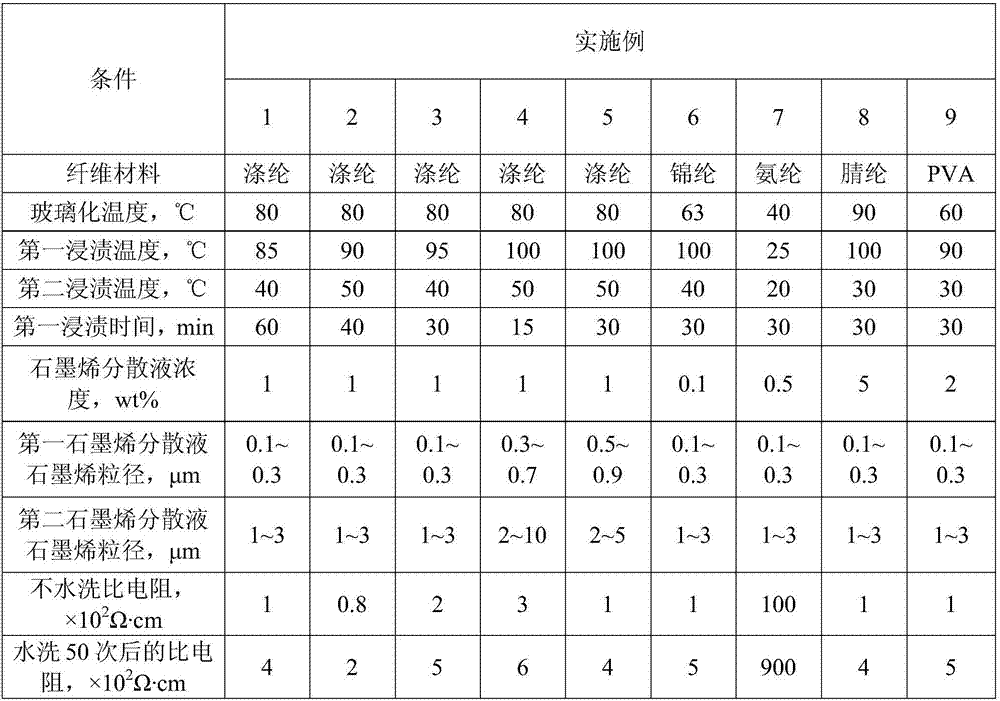

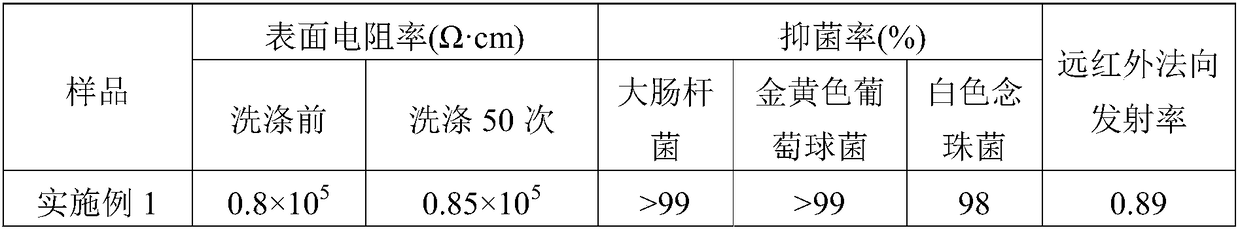

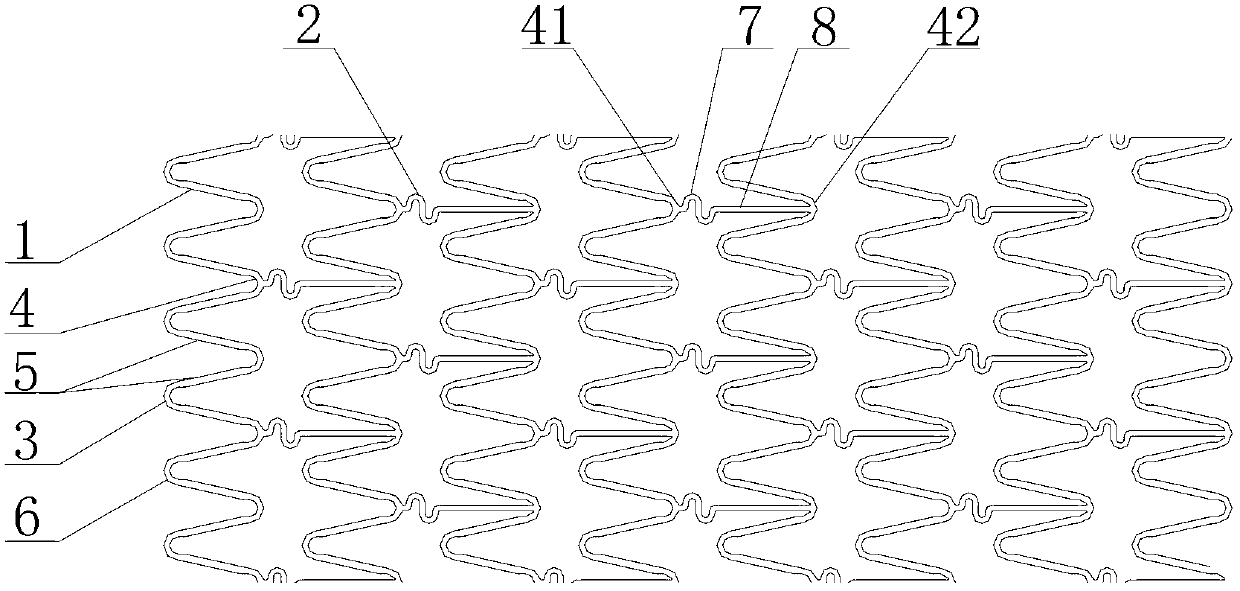

ActiveCN106930096AImprove the adhesion firmnessImprove distribution uniformityFibre typesBiomassFar infrared

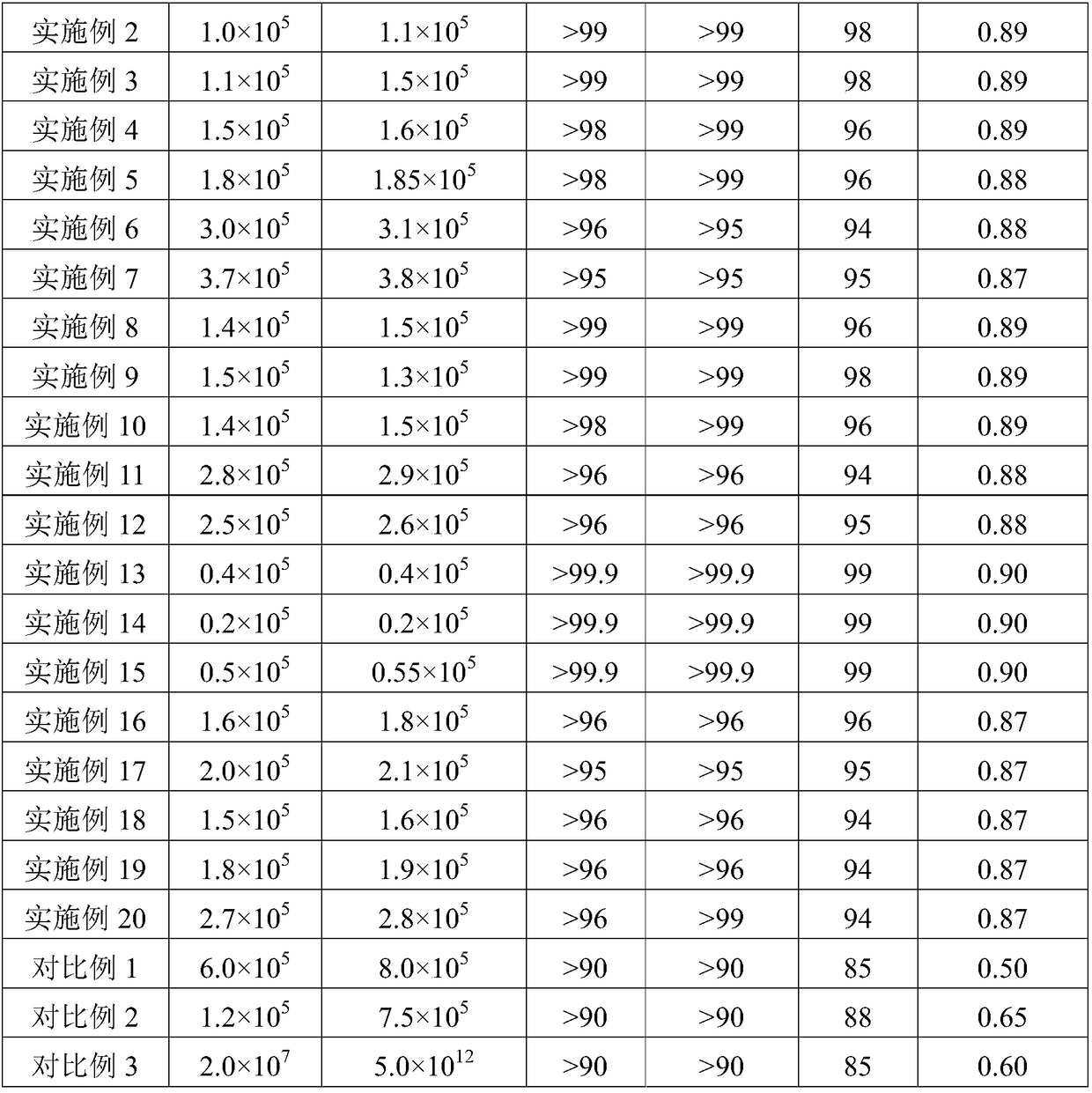

The invention relates to a modified fiber product, a preparation method and applications thereof. The modified fiber product contains modified fiber, wherein the modified fiber contains graphene substances, graphene substances with the particle size of being less than 1mum are mainly inside the modified fiber, and the graphene substances with the particle size of being 1-20mum are mainly outside the modified fiber. By reasonably matching the distribution of graphene substances inside and outside the fiber, the distribution evenness of the graphene substances can be realized, especially the distribution evenness in longitudinal direction can be realized; by distributing different particle sizes of graphene inside and outside, the density of graphene can be increased, and the conductivity of the fiber can be improved; by adding biomass graphene, the far infrared function of the fiber can be enhanced, so as to enhance the microcirculation of a human body after wearing; and graphene substances are compounded inside and outside the fiber, especially at the crystallization area inside, the firmness of the graphene substances can be greatly increased, and the washability of the fiber can be improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Antistatic graphene material modified fabric and preparation method thereof

InactiveCN108486863AAnti-staticAntistaticBiochemical fibre treatmentGrip property fibresFiberPolymer science

The invention provides an antistatic graphene material modified fabric and a preparation method thereof. A graphene material and a smoothing agent are loaded on fibers of the modified fabric. The graphene material modified fabric provided by the invention has antistatic performance; the surface resistivity is less than 1.0*10<6>omega.cm; the graphene material is directly loaded on the fibers of the fabric and has relatively high attachment firmness; even if the fabric is coated with the smoothing agent, the fabric still has an antistatic characteristic.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

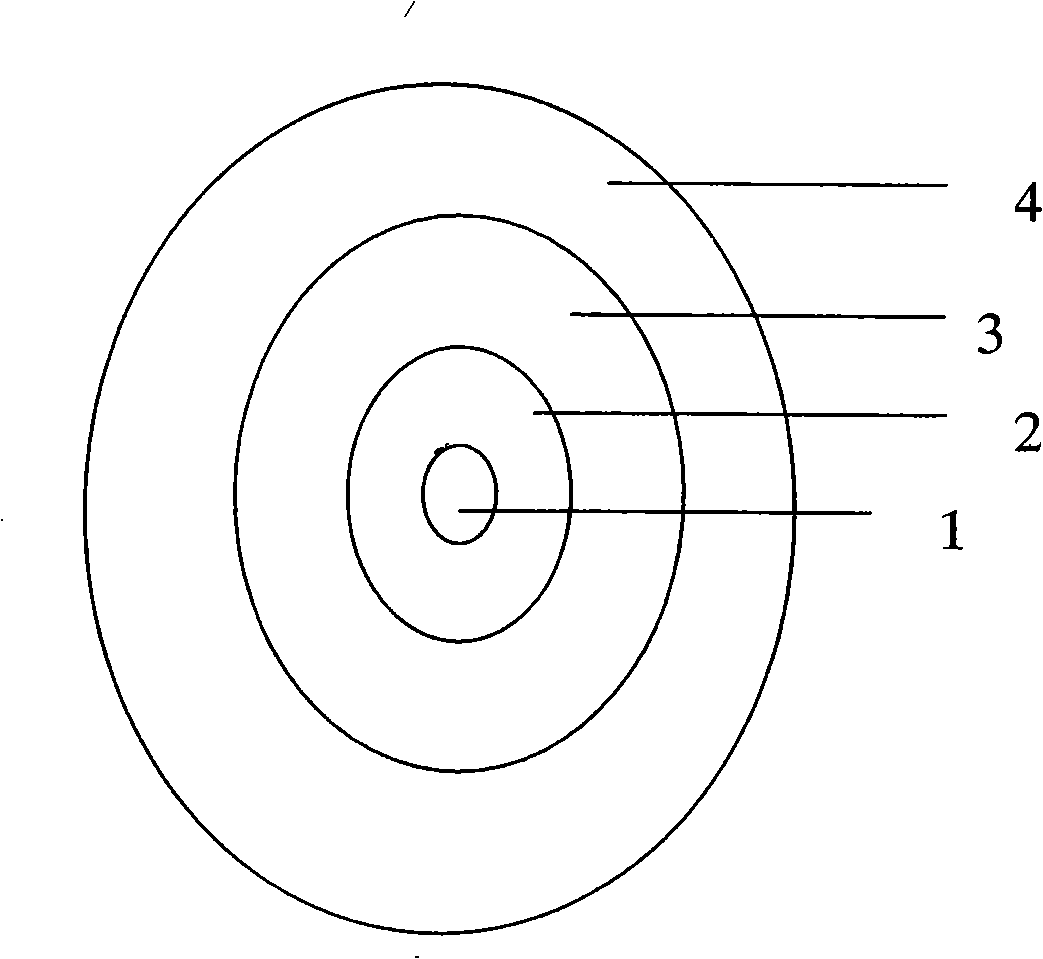

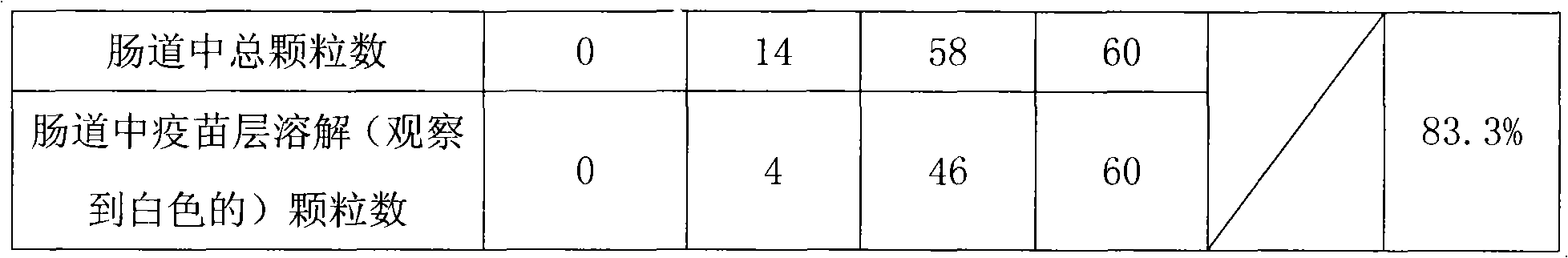

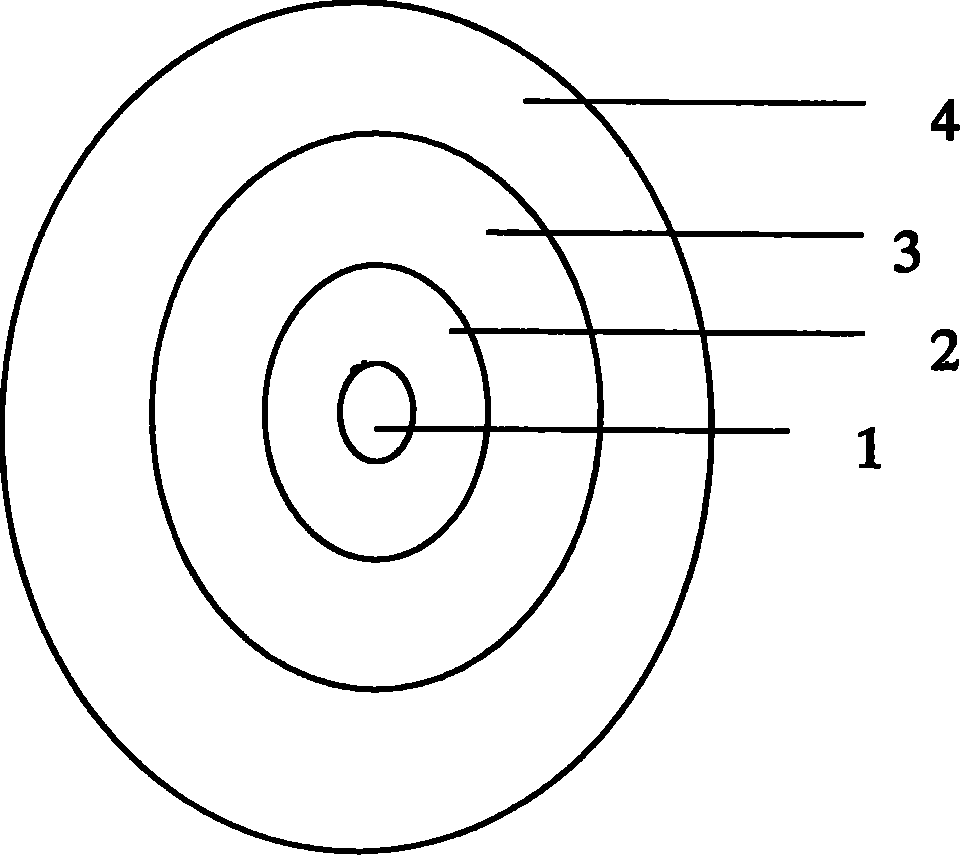

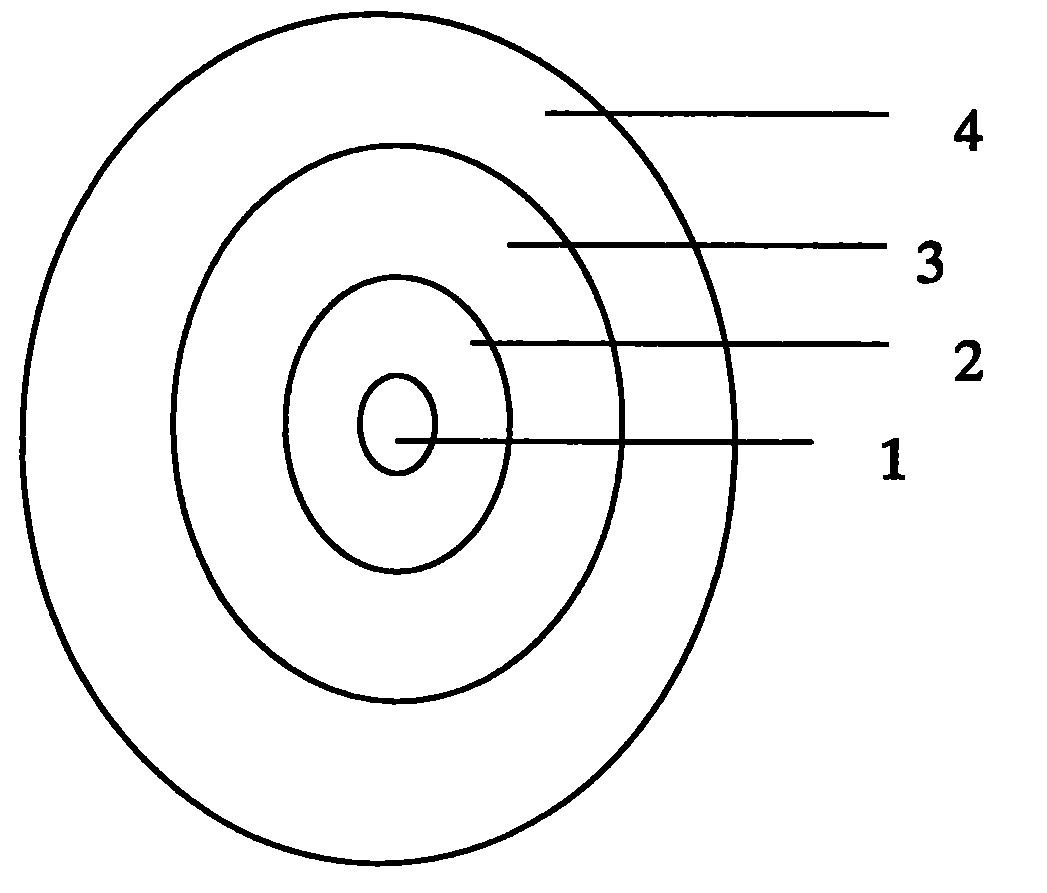

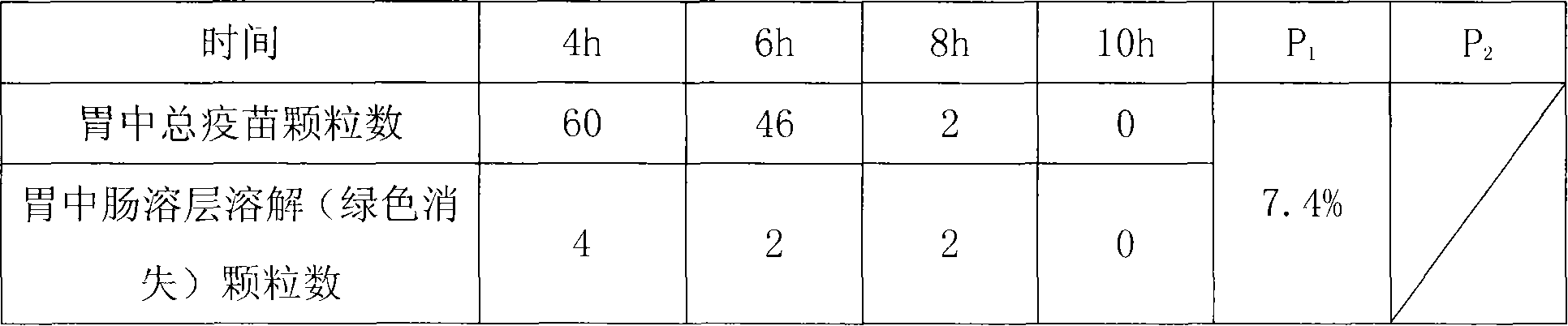

Enteric oral vaccine for fishing gear and preparation method thereof

InactiveCN101283985AImprove immune efficiencyImprove the adhesion firmnessPharmaceutical non-active ingredientsGranular deliveryPolyvinyl alcoholPolyethylene glycol

The invention relates to an enteric-coated oral vaccine for fishing, belonging to the field of oral vaccines for fishing. The enteric-coated oral vaccine for fishing comprises particles or pellets sprayed with a vaccine layer and sequentially coated with an isolating layer and an enteric-coated layer outside the vaccine layer. A dry powder composition A for spraying vaccine and coating the isolating layer comprises the following components (by weight parts) one or more film-forming agents selected from hydroxypropyl methylcellulose, polyvinyl alcohol and polyvinyl pyrrolidone 40-60 parts, one or more plasticizing agents selected from phosphoglyceride, triethyl citrate and polyethylene glycol 3-10 parts, one or more antisticking agents selected from silicon dioxide, magnesium stearate, talcum powder and titanium oxide 30-50 parts, and surfactant selected from lecithin and Tween-80 0-5 parts. The vaccine can be directionally released in intestinal tract.

Owner:天津市水产研究所 +1

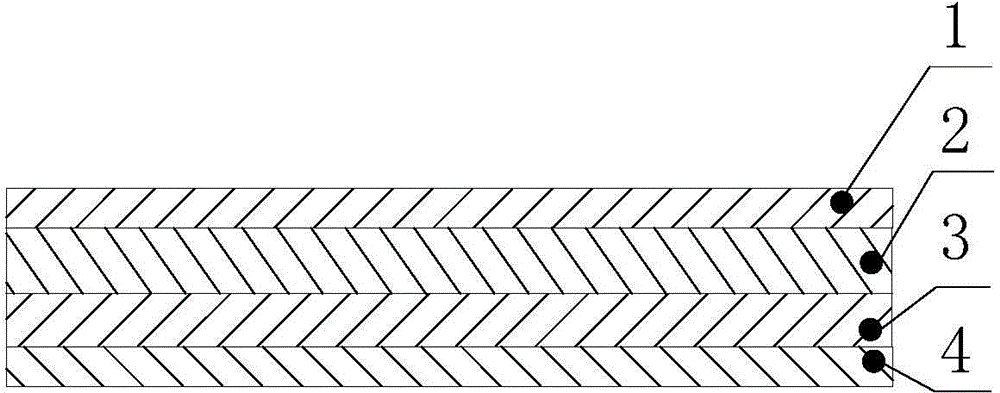

Low-friction coefficient high-resistance aluminized film and preparation method thereof

ActiveCN104786601AReduce coefficient of frictionHigh heat sealing strengthSynthetic resin layered productsHigh resistancePolymer science

The invention belongs to the technical field of aluminized films, and discloses a low-friction coefficient high-resistance aluminized film. The aluminized film is characterized by comprising a heat-seal layer, a first core layer, a second core layer and an aluminized layer which are arranged in sequence through four-layer co-extrusion casting the mass percentages of the heat-seal layer, the first core layer, the second core layer and the aluminized layer are 21%, 30%, 30% and 19% respectively; the heat-seal layer is made of ternary random copolymerization polypropylene (PP) resin and a modifying agent; the adding amount of the modifying agent is 10-15% of the mass of the ternary random copolymerization polypropylene (PP) resin; the first core layer is made of polypropylene resin; the second core layer is made of polypropylene resin; the aluminized layer is made of copolymer resin and a reinforcing agent; the adding amount of the reinforcing agent is 2-5% of the mass of the copolymer resin. The aluminized film prepared according to the method is relatively low in friction coefficient, and relatively high in heat-seal strength.

Owner:HUBEI DEWEI PACKAGING TECH

Method for carrying out treatment on surface of metal bracket by using nitrogen or inert gas

The invention discloses a method for carrying out treatment on the surface of a metal bracket by using nitrogen or inert gas. The method comprises the following steps: in the process of preparing a drug-eluting stent, carrying out treatment of cleaning and depyrogenation on the metal bracket, carrying out secondary filtration, purification and flow stabilization, and finally carrying out treatment on the surface of the stent by using the nitrogen or inert gas. The method carries out treatment of inert gas on the surface of the metal stent under the premise of adopting a completely-degradable coating, thus improving the adhesion firmness of the drug coating and the surface of the stent and simultaneously also effectively guaranteeing the uniformity of the drug coating. The drug stent has smooth surface and good adhesion firmness, thus improving the safety and effectiveness of clinical use of the drug stent.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Polysulfonamide inflaming-retarding comfortable elastic knitted plus material and preparation method thereof

ActiveCN106835476AStrong environmental protectionStrong wash resistanceWeft knittingDyeing processYarnAcrylonitrile

The invention discloses a preparation method of a polysulfonamide inflaming-retarding comfortable elastic knitted plus material. The preparation method comprises the following steps of (1) preparation of functional inflaming-retarding yarn: adopting covering yarn of which a polyamide fiber is a yarn core externally wrapped by polysulfonamide fiber as first yarn; carrying out cabling on a vinyl chloride-acrylonitrile copolymer fiber and a polytetrafluoroethylene fiber to obtain second yarn; using cationic modified polyester low stretch yarn as third yarn; (2) weaving: weaving the treated first yarn, second yarn and third yarn by adopting a knitting process into base cloth; (3) dyeing: carrying out dyeing on the base cloth by adopting cationic dye and active dye; (4) post treatment: subjecting the dyed base cloth to dehydration, oven-drying and setting treatment, so as to obtain the polysulfonamide inflaming-retarding comfortable elastic knitted plus material. The polysulfonamide inflaming-retarding comfortable elastic knitted plus material prepared by the preparation method is obvious in the superposition functions of fire resistance, comfortableness and elasticity, good in air permeability, comfortable to wear, excellent in color fastness performance, high in environmental friendliness and further simple in preparation process, and has a favorable market prospect.

Owner:NINGBO DAQIAN TEXTILE

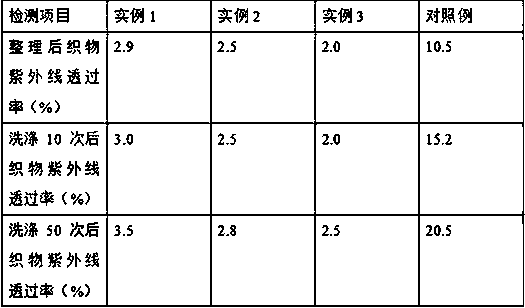

Preparation method of biomass fermentation modified anti-ultraviolet real silk fabric finishing agent

InactiveCN108130712AReduce surface polarityReduce clumpingLight resistant fibresAnimal fibresFermentationAmino acid

The invention relates to a preparation method of a biomass fermentation modified anti-ultraviolet real silk fabric finishing agent, and belongs to the technical field of preparation of a fabric finishing agent. The preparation method comprises the following steps: preparing gel liquid of monocrystal anatase type type TiO2 nanoparticles by taking tetra-n-butyl titanate as a titanium source precursor and by adopting a sol-hydrothermal synthesis process, selecting biomass materials rich in polyphenol compounds and amino acid, pulverizing and mixing the biomass materials, putting the mixture intoa greenhouse, naturally mildewing under the environment of high temperature and high humidity, sealing and fermenting the mildewed substance and water to obtain fermented filtrate, performing fermentation modification on titanium dioxide gel liquid by utilizing the fermented filtrate and finally preparing the real silk fabric finishing agent. The biomass fermentation modified anti-ultraviolet realsilk fabric finishing agent prepared by the method has extremely excellent anti-ultraviolet effect; the attachment firmness between the finishing agent and the fabric is high; after being washed formany times, the finishing agent still cannot fall off and still has extremely excellent anti-ultraviolet effect; further, the finishing agent has high anti-ultraviolet durability and has wide application prospect.

Owner:雷笑天

Check valve casting and machining process thereof

ActiveCN112430404AImprove wear resistanceSpray evenlyLiquid surface applicatorsCoatingsPolymer sciencePtru catalyst

The invention relates to the field of castings, and discloses a check valve casting and a machining process thereof. The surface of the check valve casting is treated by a surface treating agent, andthe surface treating agent comprises the following raw materials in parts by weight: 30-40 parts of styrene-maleic anhydride copolymer; 8-10 parts of Cr3Si; 4-6 parts of 1,6-hexanediol diacrylate; 6-8parts of 4-(benzylthio)phenol; 1-2 parts of a catalyst; and 40-50 parts of isooctyl alcohol polyoxy ether ester. The processing technology comprises the following steps: S1, preparing the surface treating agent; S2, conducting thermal spraying; and S3, carrying out post-processing treatment. Compared with the prior art, the invention has the following advantages and effects: Cr3Si is adopted to improve the wear resistance of the surface treating agent, the styrene-maleic anhydride copolymer and Cr3Si are blended to improve the dispersity, and the 1,6-hexanediol diacrylate and 4-(benzylthio)phenol products are further mixed to prepare a copolymerization mixture with large molecular weight and a compact structure; the wear resistance of the check valve casting is improved; and according tothe machining process, the modes of preheating, thermal spraying and hole sealing treatment are adopted, and the performance of the check valve casting is better.

Owner:WENZHOU HAIGE VALVE CO LTD

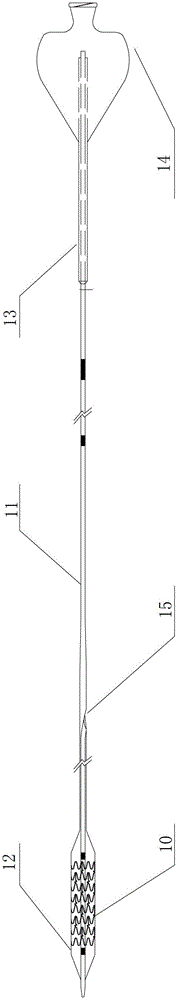

Cobalt-chromium alloy arterial stent system with full biodegrade medical coating

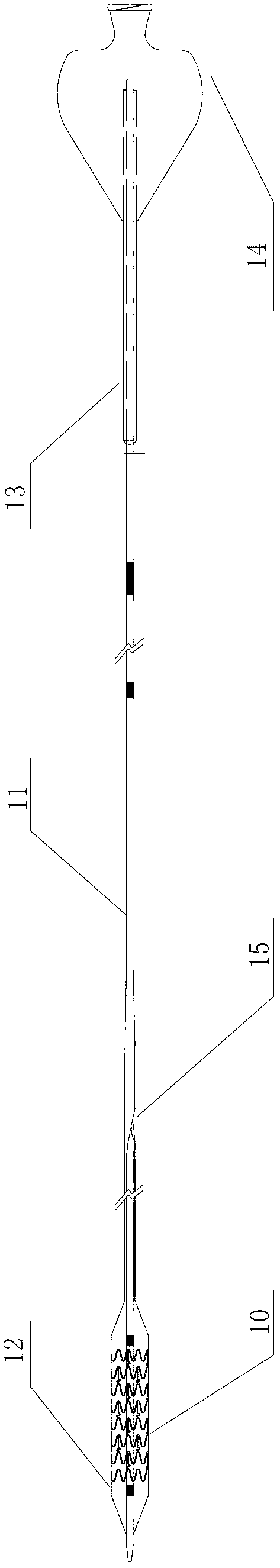

ActiveCN103212117AImprove mechanical propertiesGood biocompatibilityStentsSurgeryCoronary arteriesTransport system

The invention provides a cobalt-chromium alloy arterial stent system with a full biodegrade medical coating. The system comprises a transport system and a cobalt-chromium alloy arterial stent which has a full biodegrade medical coating and is sleeved on the transport system. The transport system comprises a push rod, a sacculus and a jacket respectively fixedly connected to both ends of the push rod, and a handle with a Luer joint. A cone-shaped hardened guide wire is arranged at the sacculus end of the push rod. The cobalt-chromium alloy arterial stent with the full biodegrade medical coating is sleeved on the sacculus. The system can avoid damage of the coating to the maximum extent, improve the retaining force between the bracket and the transport system greatly, prevent the probability that the bracket is out of load in the transport process, and reduce the clinical use risk, so that the problems of coronary artery stenosis and restenosis are effectively solved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

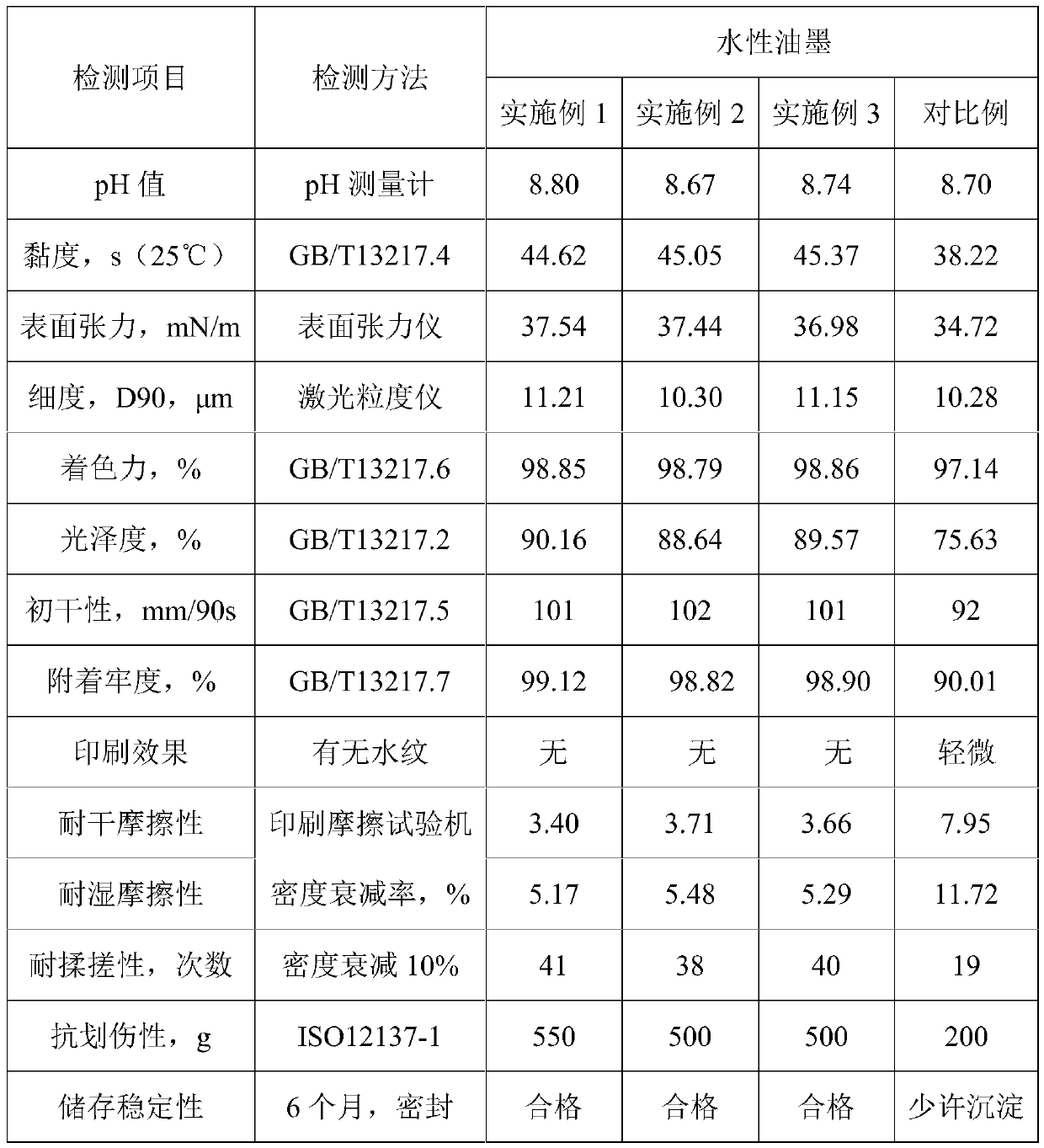

Method for preparing flexography water-based ink for plastic film

InactiveCN109943144AImprove basic performanceStorage stability qualifiedInksWater basedPolymer science

The invention relates to a method for preparing flexography water-based ink for a plastic film. The method comprises the following steps: (1) preparing a water-based acrylate emulsion by emulsion polymerization; (2) adding dicyclopentadiene acrylic acid ester resin, hydroxyethyl cellulose, emulsifier and isopropanol into water to prepare a water-based dicyclopentadiene acrylic acid ester emulsion;and (3) preparing color paste from the water-based dicyclopentadiene acrylic acid ester emulsion with pigment, dispersant, a defoaming agent and part of water, and adding the color paste, water-basedacrylate emulsion, a base material wetting agent, a flatting agent and gaseous silicon dioxide into the remained water, and mixing. The water-based ink is excellent in basic performance, can meet theusing requirement of flexography, has strong printing adhesion and high adhering firmness on a plastic film, especially a polyolefin film, has high ink film strength and no water mark phenomenon, hasexcellent dry / wet friction resistance, rubbing resistance and scratch resistance, has high printing quality, and is suitable for package printing by using a plastic film as a printing stock.

Owner:郑州知淘信息科技有限责任公司

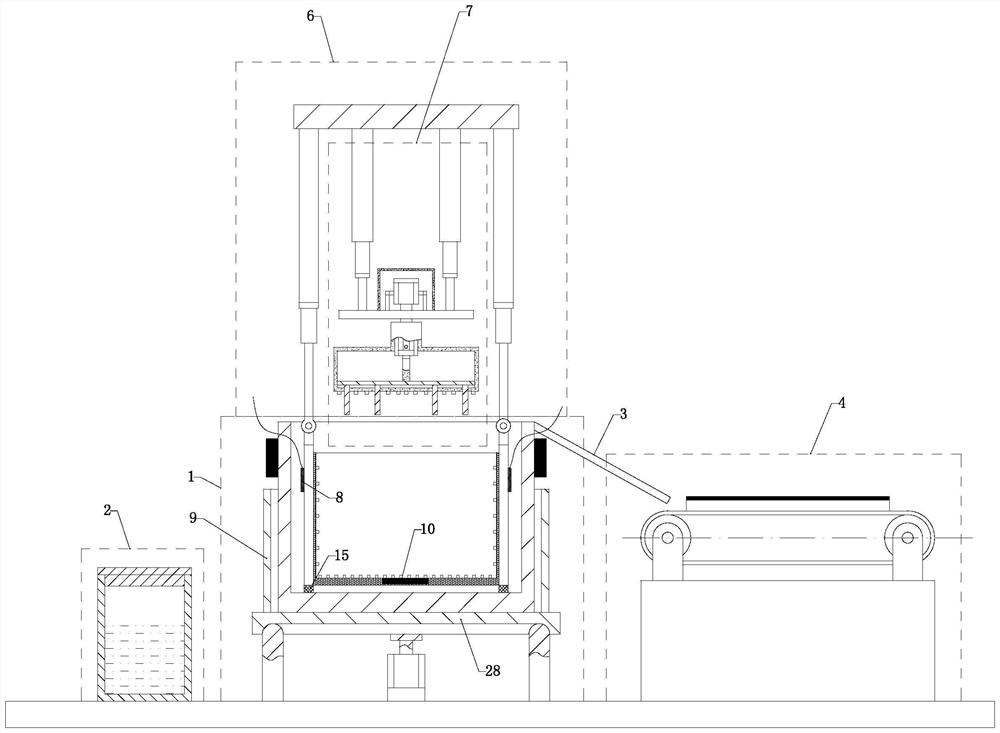

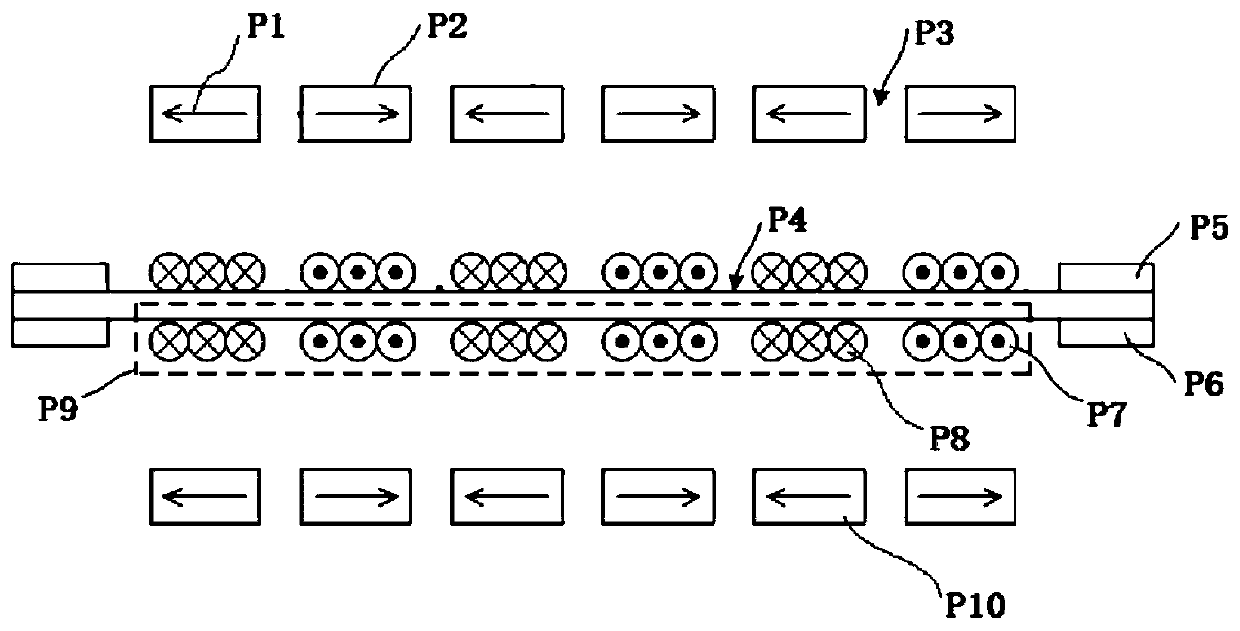

Aramid fiber dyeing process and system

ActiveCN112575470AImprove dyeing effectHigh color fastnessLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalAramidDyeing

The invention relates to the technical field of aramid fiber dyeing, in particular to an aramid fiber dyeing process and system. The aramid fiber dyeing process comprises the steps of S1, loading aramid fiber materials to be dyed into an aramid fiber dyeing system sequentially, and performing material preparation; S2, putting the prepared aramid fibers into the aramid fiber dyeing system; S3, controlling an electric field in the aramid fiber dyeing system to be in a changing state for dyeing; S4, realizing dyeing through cooperation of a moving magnetic field and ionization; S5, in the dyeingprocess, enabling the aramid fibers to be continuously kneaded and extruded in the aramid fiber dyeing system; S6, before dyeing is finished, enabling the dyed aramid fibers to be subjected to preliminary color fastness sampling detection regularly to judge the current dyeing condition; S7, after the dyeing condition meets the requirement, enabling the dyed aramid fibers to be subjected to deep color fixing treatment; and S8, drying the aramid fibers subjected to color fixation, and collecting the dried aramid fibers for later use. The aramid fiber dyed by the process is good in dyeing effect,high in color fastness and relatively high in dyeing uniformity.

Owner:SHANDONG GAOMIAN INTELLIGENT FIBER DYEING TECH CO LTD

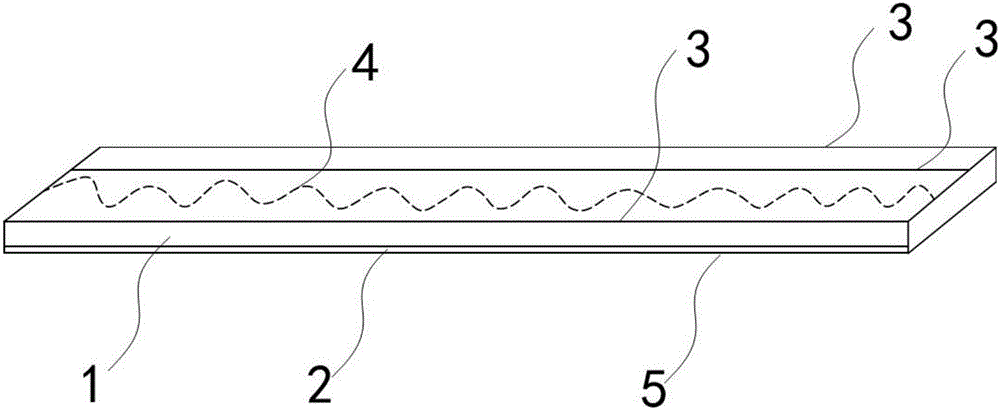

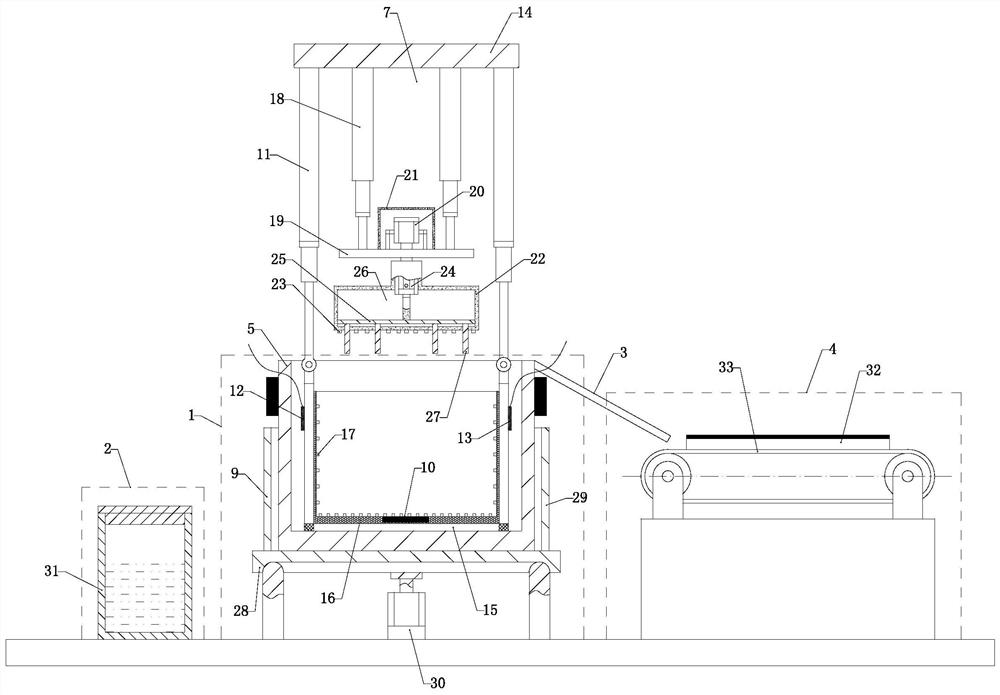

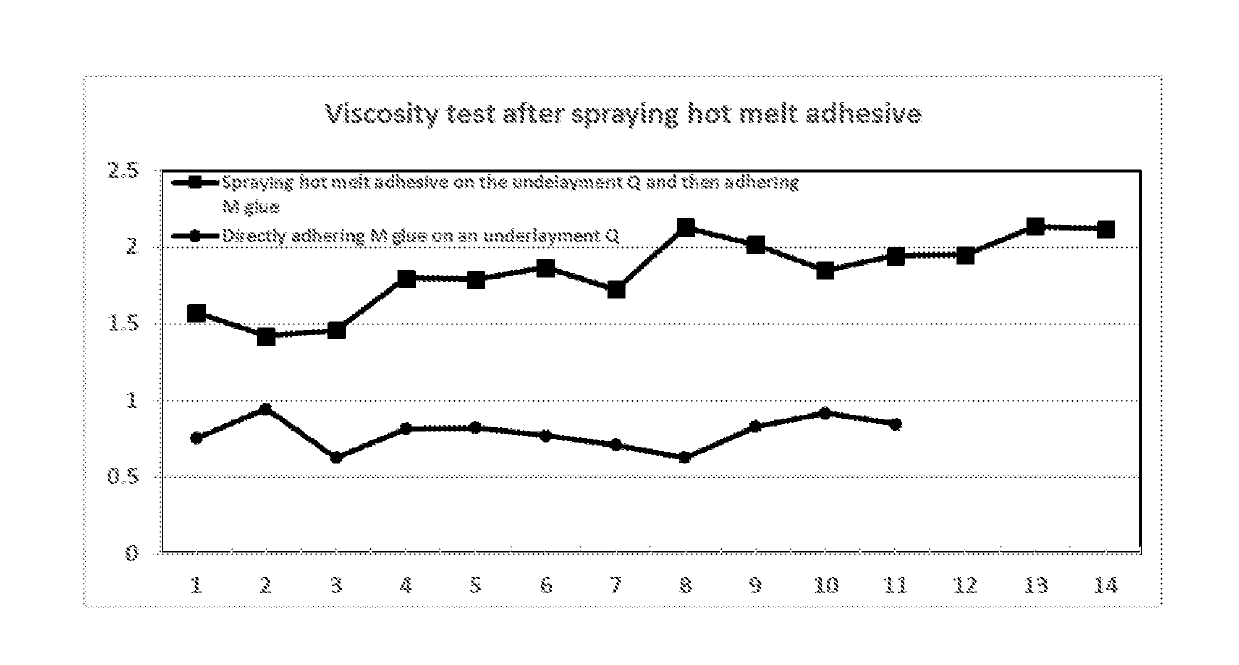

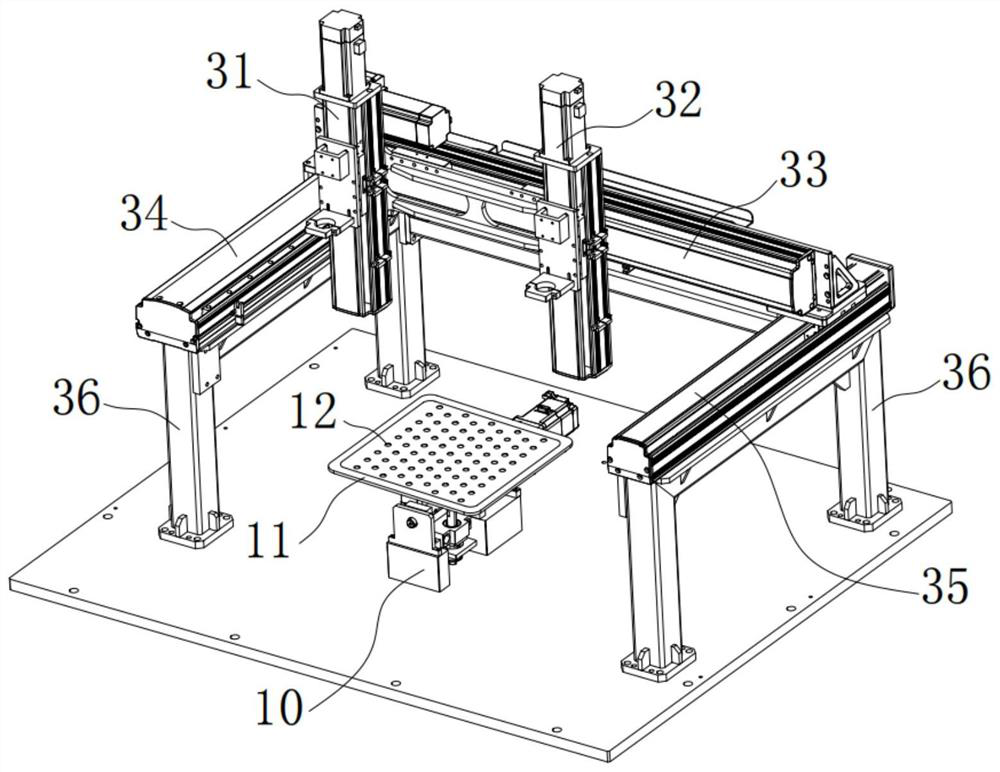

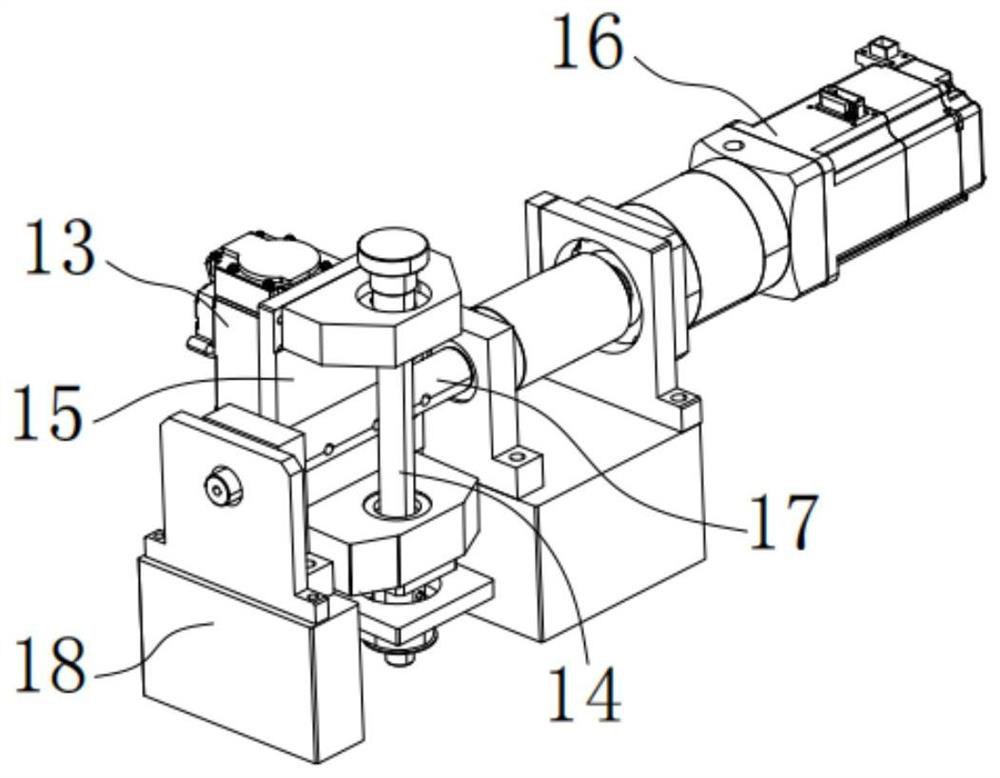

Process for spraying back-adhesive on CMP pad

InactiveUS20190105848A1Avoid pollutionImprove the adhesion firmnessAdhesive processesLiquid surface applicatorsHot meltEngineering

A process for spraying back-adhesive of a CMP pad, includes steps of: horizontally placing an underlayment on middle portions of an upper conveying roller and a lower conveying roller of a hot melt machine for feeding; providing an upper layer glue-coated paper closely attached with an upper surface of the underlayment on the upper conveying roller, providing a lower layer glue-coated paper closely attached with a lower surface of the underlayment on the lower conveying roller; spraying hot melt adhesive on an upper surface of the lower layer glue-coated paper via an ejector nozzle of the hot melt machine; wherein the upper layer glue-coated paper, the underlayment and the lower layer glue-coated paper are transmitted and adhered with each other on the upper conveying roller and the lower conveying roller.

Owner:CHENGDU TIMES LIVE SCI & TECH

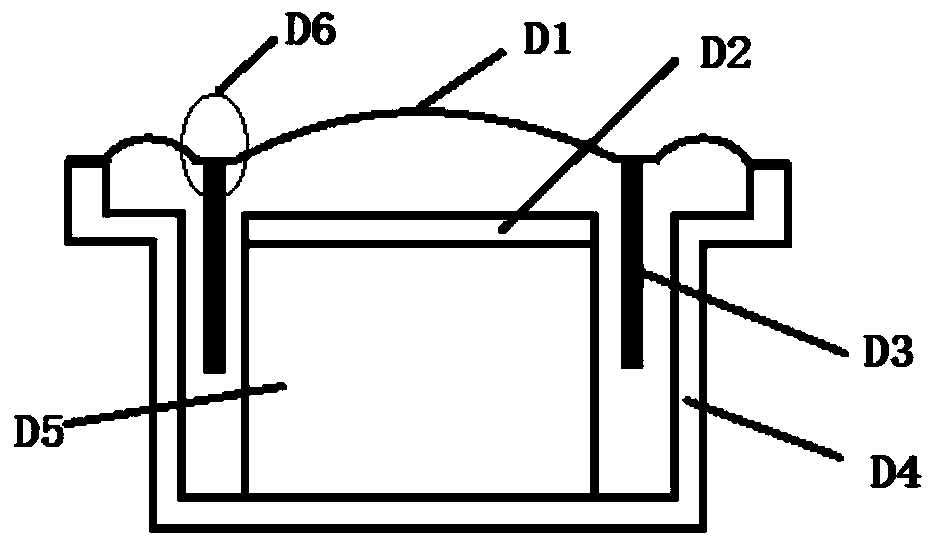

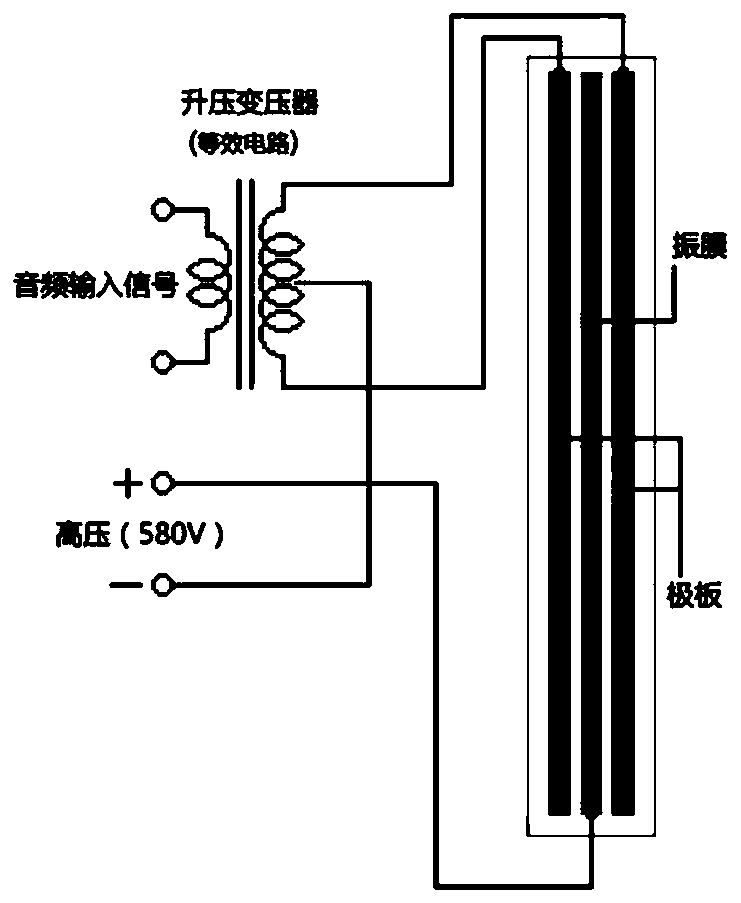

Planar coil diaphragm loudspeaker and application thereof

The invention discloses a planar coil diaphragm loudspeaker, which comprises an outer shell, wherein a membrane assembly, a magnet assembly and a supporting assembly are packaged in the outer shell; the membrane assembly at least comprises a coil, the two ends of the coil are each provided with an end point, one end point is located in the coil, and the other end point is located outside the coil;the number of the supporting assemblies is at least one; the supporting assemblies are used for supporting the membrane assembly; the surfaces, making contact with the membrane assembly, of the supporting assemblies are provided with bonding pads connected with end points located outside the coil; and the supporting assemblies are further provided with bonding pads for audio current input and bonding pads for audio current output. Compared with the prior art, the planar coil diaphragm loudspeaker has the advantages that the problem of how to effectively connect the internal end point of the closed coil with the outside is solved, the integrity of the membrane is not damaged, the area of the membrane is utilized to the maximum extent, damage to the film caused by spot welding or conductiveadhesive bonding after perforation is avoided, and damage to the integrity of the film is further avoided.

Owner:颜君玲

A kind of hydrocarbon oxidation catalyst and preparation method thereof

ActiveCN104525231BShorten the induction periodHigh yieldOrganic chemistryPhysical/chemical process catalystsBenzeneWorking environment

The invention discloses a hydrocarbon oxidation catalyst and a preparation method thereof, in particular to a catalyst for preparing maleic anhydride by using benzene as a raw material through gas-solid phase catalytic oxidation reaction. The catalyst is prepared by using a salt or oxide containing V, Mo, Ti, P, Na, Ni as a precursor to prepare a solution or suspension, drying, activating, homogeneously emulsifying, and spraying. The invention solves the problems of long induction period of existing catalysts, easy fall-off of active substances, low utilization rate of catalyst raw materials, poor working environment for workers and serious environmental pollution.

Owner:DALIAN DRAGON WIN CATALYTIC

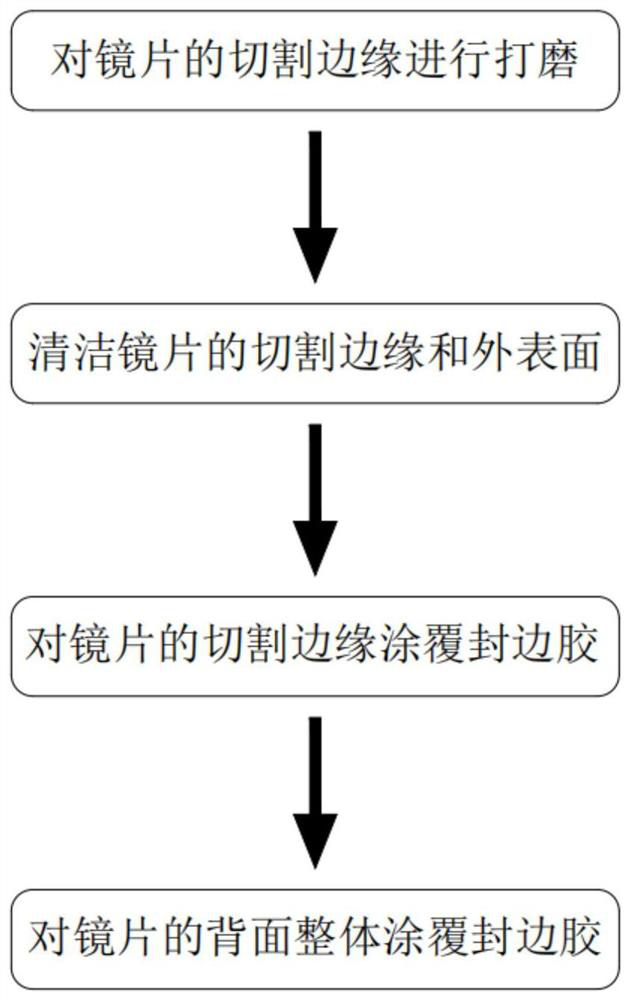

Anti-oxidation treatment method and device for mirror

PendingCN113426649AImprove protectionIncrease the attachment surfacePretreated surfacesCoatingsAdhesiveAnti oxidant

The invention discloses an anti-oxidation treatment method for a mirror, and belongs to the technical field of mirror treatment. The anti-oxidation treatment method for the mirror comprises the following steps of polishing the cut edge of a mirror; cleaning the cut edge and the outer surface of the mirror; coating the cut edge of the mirror with an edge sealing adhesive which covers the glass layer of the cut edge of the mirror, wherein the edge sealing adhesive is a viscous colloidal fluid, and the viscous colloidal fluid contains an antioxidant; and coating the whole back surface of the mirror with the edge sealing adhesive, wherein the cut edge edge sealing adhesive layer of the mirror and the back face edge sealing adhesive layer of the mirror are connected into a whole. The cut edge and the back surface of the mirror are integrally coated with the edge sealing adhesive, and the edge sealing adhesive covers the glass layer of the cut edge of the mirror, so that the attachment surface of the edge sealing adhesive is expanded, and the attachment firmness of the edge sealing adhesive layer of the cut edge of the mirror is improved; and compared with the mode of manually coating the edge sealing adhesive in the prior art, the anti-oxidation treatment method for the mirror has the advantages that the stability of the coating quality is better, the coating efficiency is higher, and the protection effect on the mirror is better.

Owner:佛山市银鑫玻璃镜业有限公司

Hydrocarbon oxidation catalyst and method for preparing same

InactiveCN109746009AShorten the induction periodHigh yieldOrganic chemistryPhysical/chemical process catalystsBenzeneCatalytic oxidation

The invention discloses a hydrocarbon oxidation catalyst and a method for preparing the same, and particularly relates to catalysts for preparing maleic anhydride from benzene by means of gas-solid phase catalytic oxidation reaction. The benzene is used as a raw material for the maleic anhydride. The method includes preparing solution or suspension from salt or oxide with V, Mo, Ti, P, Na and Ni;carrying out drying, activation, homogenization and emulsification and spraying to prepare the hydrocarbon oxidation catalyst. The salt or the oxide is used as a precursor. The hydrocarbon oxidation catalyst and the method have the advantage that the problems of long induction periods of existing catalysts, vulnerability to falling of active matters, low utilization rates of raw materials for thecatalysts, poor work environments for workers and severe environmental pollution can be solved by the aid of the hydrocarbon oxidation catalyst and the method.

Owner:张泳

Check valve casting and its processing technology

ActiveCN112430404BImprove wear resistanceSpray evenlyLiquid surface applicatorsCoatingsPtru catalystCheck valve

The application relates to the field of castings, and discloses a check valve casting and its processing technology. Check valve casting, the surface of the check valve casting is processed by a surface treatment agent, and the surface treatment agent includes the following raw materials in parts by weight: 30-40 parts of styrene-maleic anhydride copolymer; 8-10 parts of Cr 3 Si; 4‑6 parts of 1,6‑hexanediol diacrylate; 6‑8 parts of 4‑(benzylthiol)phenol; 1‑2 parts of catalyst; 40‑50 parts of isooctyl polyoxyether ester; The processing technology is: S1. Surface treatment agent preparation; S2. Thermal spraying; S3. Post-processing; This application has the following advantages and effects: using Cr 3 Si enhances the wear resistance of surface treatments, styrene‑maleic anhydride copolymer and Cr 3 Si blending to improve dispersion, and further mixing the products of 1,6-hexanediol diacrylate and 4-(benzylthiol) phenol to obtain a copolymer mixture with a larger molecular weight and a dense structure to improve the non-return The wear resistance of valve castings; the processing technology adopts the method of preheating, thermal spraying and sealing treatment, and the performance of check valve castings is better.

Owner:WENZHOU HAIGE VALVE CO LTD

Ultraviolet (UV) screen plastic film printing ink and method for preparing same

The present invention relates to the field of ink technology, in particular to a UV screen printing plastic ink and a preparation method thereof. The UV screen printing plastic ink of the present invention consists of the following raw materials in parts by weight: 18-28 parts of polyurethane acrylate, 16-25 parts of polyester Acrylate, 6~15 parts of solid acrylic resin, 2~8 parts of TPGDA, 7~15 parts of TMPTA, 4~12 parts of HDDA, 14~22 parts of pigment powder, 1~3 parts of dispersant, 0.2~1.2 parts of silicone disinfectant Foaming agent, 1~4 parts of silicone leveling agent, 1~3 parts of photoinitiator, 0.2~1.5 parts of adhesion promoter. The present invention uses solid acrylic resin as one of the base materials, which has better flexibility and adhesion, greatly improves the printing adaptability of plastic inks, and the base materials urethane acrylate and polyester acrylate have excellent adhesion, The adhesion firmness of the present invention is further enhanced, the printing adaptability is better, and the printing effect is good.

Owner:东莞市佳烨化工科技有限公司

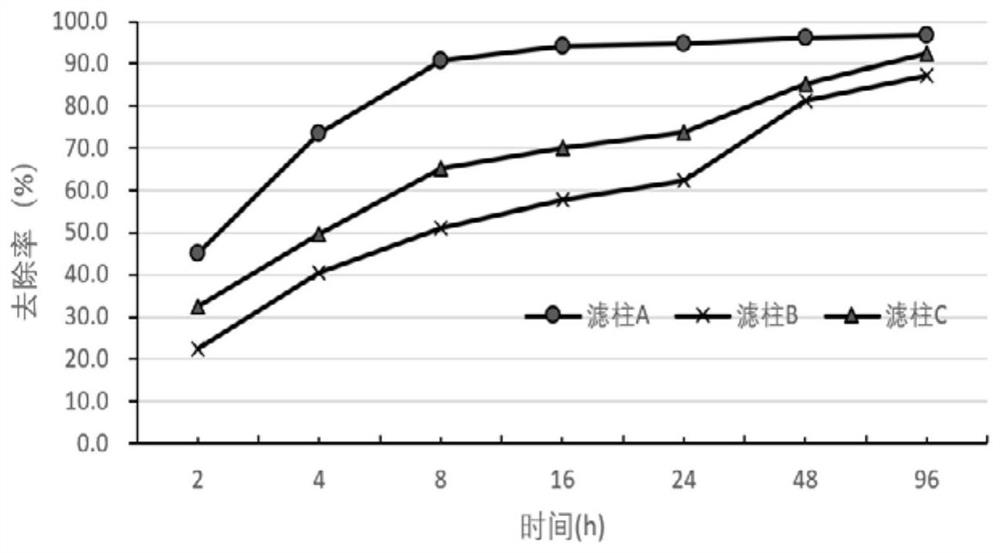

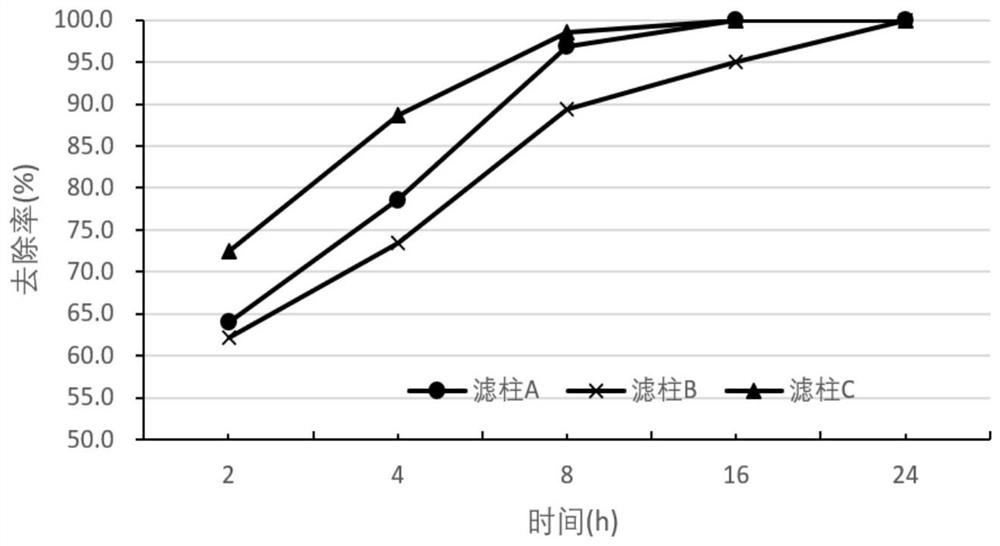

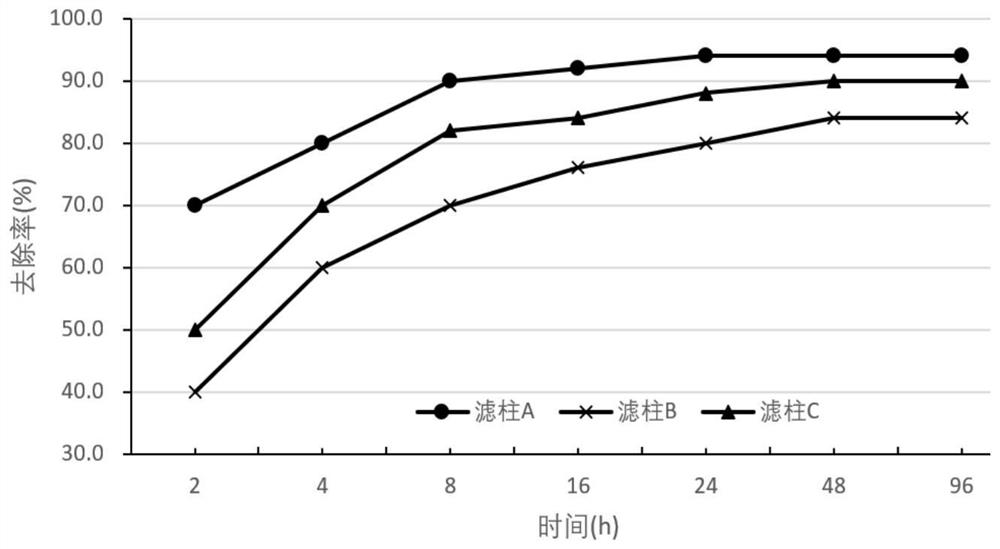

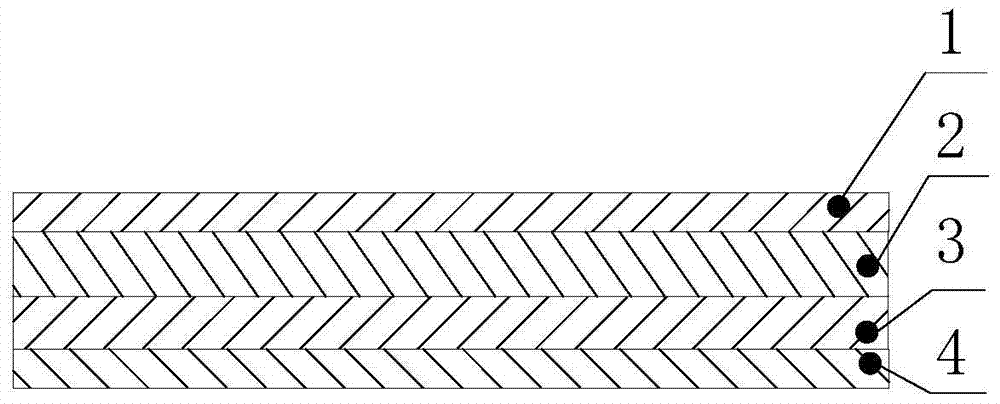

A kind of composite filter material for biological soil deodorization and its application

ActiveCN113082998BImprove the adhesion firmnessSimple methodGas treatmentDispersed particle separationMicroorganismCarbonization

The invention provides a composite filter material for biological soil deodorization and application thereof. The composite filter material is mainly composed of semi-weathered sandy soil filter material and wood-based granular carbon carrier solidified microbial filler. The semi-weathered sandy soil filter material has a diameter of 1-3mm, a porosity of 20%-40%, and a specific surface area of 6-10m2 / g. Wood-based granular carbon carrier solidified microbial filler carrier is carbonized broken wood particles, the particle diameter is 3-5mm, the carbonization condition is 600°C-700°C anoxic condition, and the carbonization time is 3-5h. The microorganism used in the wood-based granular carbon carrier solidified microbial filler is a kind of Facultative Citrobacter ZT‑S5 (Citrobacter sp.), and the strain preservation number is CGMCC No.15120. Maintain the abundance and activity of microorganisms, and quickly restart after a long period of shutdown, so that the biological soil deodorization system can quickly meet the waste gas treatment requirements. The invention is easy to obtain materials, and the wood-based granular carbon carrier solidifies the microbial filler to make a simple process, and the source of the Citrobacter used is collected from a sewage treatment plant, without secondary pollution and ecological risk.

Owner:江苏博恩环境工程成套设备有限公司

A kind of low friction coefficient high barrier aluminized film and preparation method thereof

ActiveCN104786601BImprove flatnessHigh glossSynthetic resin layered productsHigh resistancePolymer science

Owner:HUBEI DEWEI PACKAGING TECH

A kind of high-performance recycled concrete and its preparation process

InactiveCN110540389BImprove work performanceImprove compactnessBuilding material handlingCrushed stoneProcess engineering

The invention discloses a high-performance recycled concrete and a preparation process thereof, and relates to the technical field of concrete preparation, which comprises the following raw materials in parts by weight: 220-240 parts of cement; 140-160 parts of fly ash; 60-80 parts of mineral powder 600-800 parts of modified recycled coarse aggregate; 500-700 parts of natural gravel; 600-700 parts of machine-made sand; 20-40 parts of reinforcing agent; 40-60 parts of silicon powder; 180‑200 copies. By adjusting the ratio of various raw materials of concrete, adding reinforcing agent and modifying recycled aggregate, the working performance of concrete can be effectively improved, and the compactness and overall strength of concrete can be improved.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

Dope of acidic phosphate in use for jet printing symbols in high temperature

ActiveCN100591730CSatisfy the use effectImprove the adhesion firmnessCoatingsMagnesium phosphateAdhesive

This invention relates to acidic phosphate paint for high-temperature spraying onto steel green bodies and steel coils. The acidic phosphate paint comprises: adhesive, pigment and dispersant at a weight ratio of 100: (5-25): (0.5-10). The adhesive is a transparent liquid containing acidic aluminum phosphate and magnesium phosphate, and the solid content is 40-70 wt.%. In the raw materials of the adhesive, the mol ratio of PO43-, Al3+ and Mg2+ is (2.1-3.0) : 1 : (0.4-0.6). The paint has the solid content of 25-50 wt.%, and a pH value of 2-4. The paint has such advantages as stable properties and low corrosion, and can be directly sprayed onto steel green bodies and steel coils higher than 200 deg.C. The obtained patterns have high adhesiveness.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

A kind of sulfonamide flame-retardant comfortable elastic knitted fabric and preparation method thereof

ActiveCN106835476BStrong environmental protectionStrong wash resistanceWeft knittingDyeing processYarnAcrylonitrile

The invention discloses a preparation method of a polysulfonamide inflaming-retarding comfortable elastic knitted plus material. The preparation method comprises the following steps of (1) preparation of functional inflaming-retarding yarn: adopting covering yarn of which a polyamide fiber is a yarn core externally wrapped by polysulfonamide fiber as first yarn; carrying out cabling on a vinyl chloride-acrylonitrile copolymer fiber and a polytetrafluoroethylene fiber to obtain second yarn; using cationic modified polyester low stretch yarn as third yarn; (2) weaving: weaving the treated first yarn, second yarn and third yarn by adopting a knitting process into base cloth; (3) dyeing: carrying out dyeing on the base cloth by adopting cationic dye and active dye; (4) post treatment: subjecting the dyed base cloth to dehydration, oven-drying and setting treatment, so as to obtain the polysulfonamide inflaming-retarding comfortable elastic knitted plus material. The polysulfonamide inflaming-retarding comfortable elastic knitted plus material prepared by the preparation method is obvious in the superposition functions of fire resistance, comfortableness and elasticity, good in air permeability, comfortable to wear, excellent in color fastness performance, high in environmental friendliness and further simple in preparation process, and has a favorable market prospect.

Owner:NINGBO DAQIAN TEXTILE

Enteric oral vaccine for fishing gear and preparation method thereof

InactiveCN101283985BImprove immune efficiencyImprove the adhesion firmnessPharmaceutical non-active ingredientsGranular deliveryPolyvinyl alcoholPolyethylene glycol

The invention relates to an enteric-coated oral vaccine for fishing, belonging to the field of oral vaccines for fishing. The enteric-coated oral vaccine for fishing comprises particles or pellets sprayed with a vaccine layer and sequentially coated with an isolating layer and an enteric-coated layer outside the vaccine layer. A dry powder composition A for spraying vaccine and coating the isolating layer comprises the following components (by weight parts) one or more film-forming agents selected from hydroxypropyl methylcellulose, polyvinyl alcohol and polyvinyl pyrrolidone 40-60 parts, oneor more plasticizing agents selected from phosphoglyceride, triethyl citrate and polyethylene glycol 3-10 parts, one or more antisticking agents selected from silicon dioxide, magnesium stearate, talcum powder and titanium oxide 30-50 parts, and surfactant selected from lecithin and Tween-80 0-5 parts. The vaccine can be directionally released in intestinal tract.

Owner:天津市水产研究所 +1

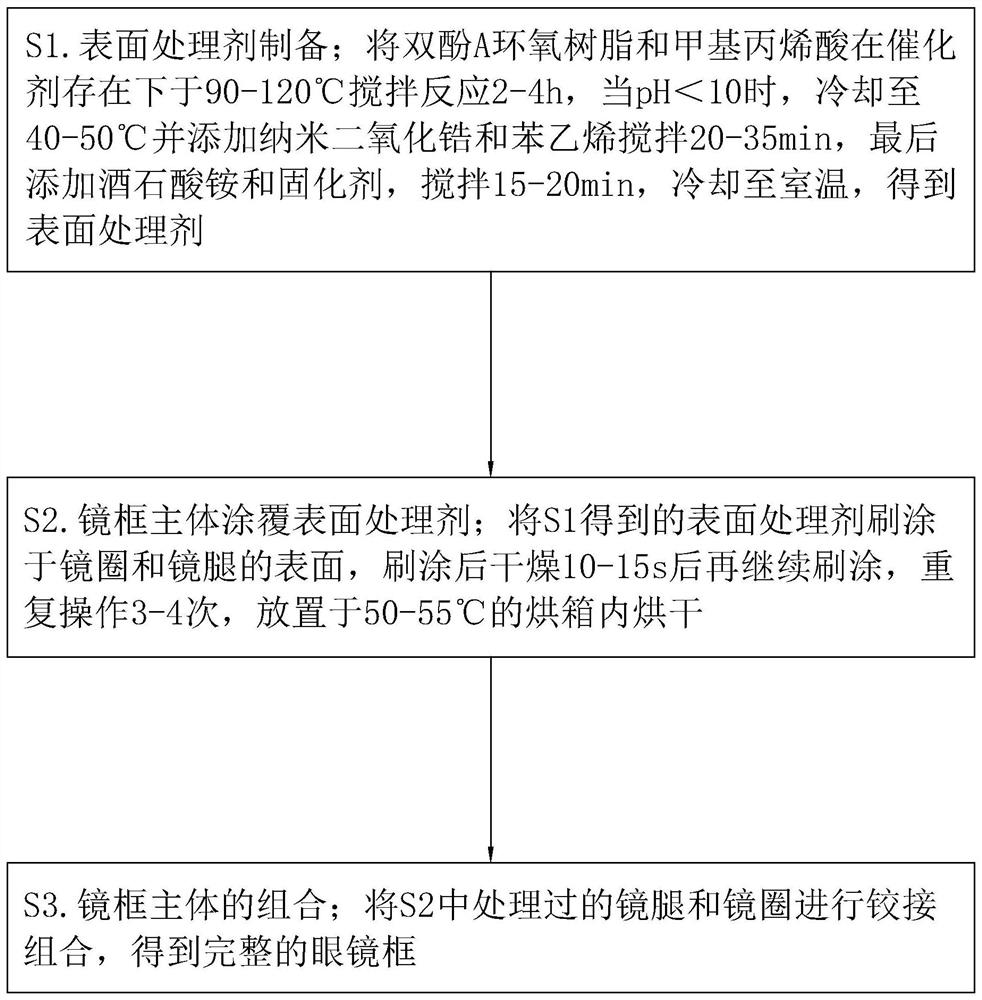

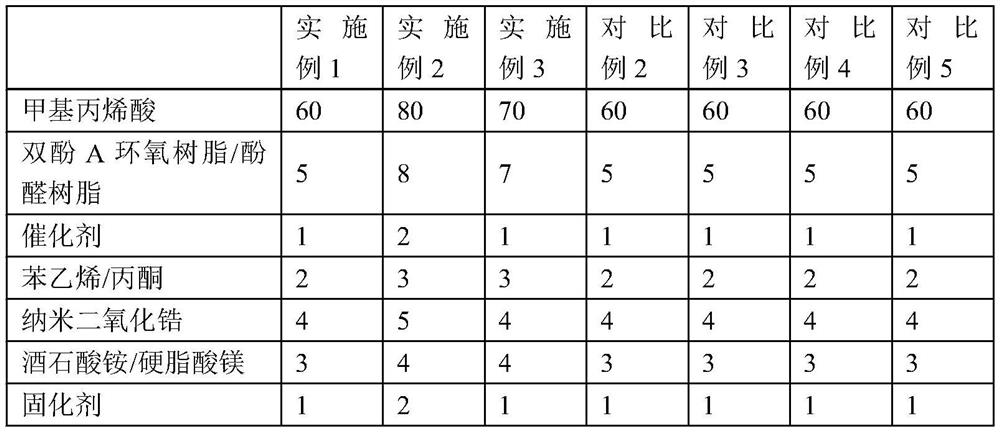

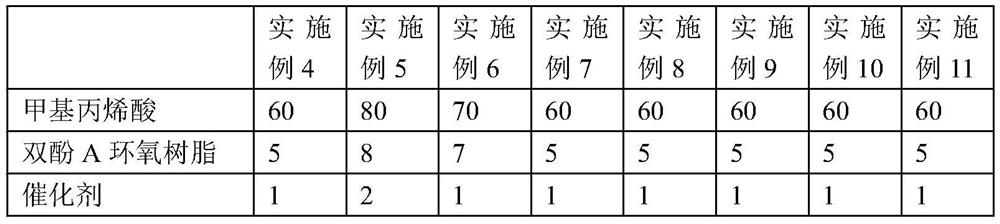

A kind of corrosion-resistant spectacle frame and its processing technology

ActiveCN112068328BImprove corrosion resistanceEvenly dispersedAnti-corrosive paintsNon-optical partsPtru catalystFirming agent

This application relates to the field of glasses accessories, and discloses a corrosion-resistant glasses frame and its processing technology. The glasses frame includes a frame body composed of a mirror ring and temple legs. The frame body is copper alloy, and the frame body is treated with a surface treatment agent. , the surface treatment agent includes the following raw materials in parts by weight: 60-80 parts of methacrylic acid; 5-8 parts of bisphenol A epoxy resin; 1-2 parts of catalyst; 2-3 parts of styrene; 4-5 parts of nanometer Zirconia; 3-4 parts ammonium tartrate; 1-2 parts curing agent. The application has the following advantages and effects: the catalyst catalyzes the reaction of methacrylic acid and bisphenol A epoxy resin to prepare epoxy vinyl ester resin, the ester bond contained is next to the terminal double bond, and the double bond is cured to form a three-dimensional network to protect the ester group , so that the ester bonds that are vulnerable to water or acid and alkali attacks are protected, thereby improving corrosion resistance.

Owner:温州市皓朗眼镜有限公司

Preparation method for preparing maleic anhydride catalyst through light alkane selective oxidation

InactiveCN109772392AShorten the induction periodHigh yieldOrganic chemistryPhysical/chemical process catalystsWorking environmentMaleic anhydride

The invention discloses a preparation method for preparing a maleic anhydride catalyst through light alkane selective oxidation. The catalyst is prepared by adopting salts or oxides containing V, Mo,Ti, P, Na and Ni as precursors to obtain a solution or suspension, drying, activating, homogenizing, emulsifying and spraying. The preparation method disclosed by the invention solves the problems oflong induction period, easiness in falling of active matters, low utilization rate of catalyst raw materials, poor working environment of workers and heavy environmental pollution of an existing catalyst.

Owner:李磊

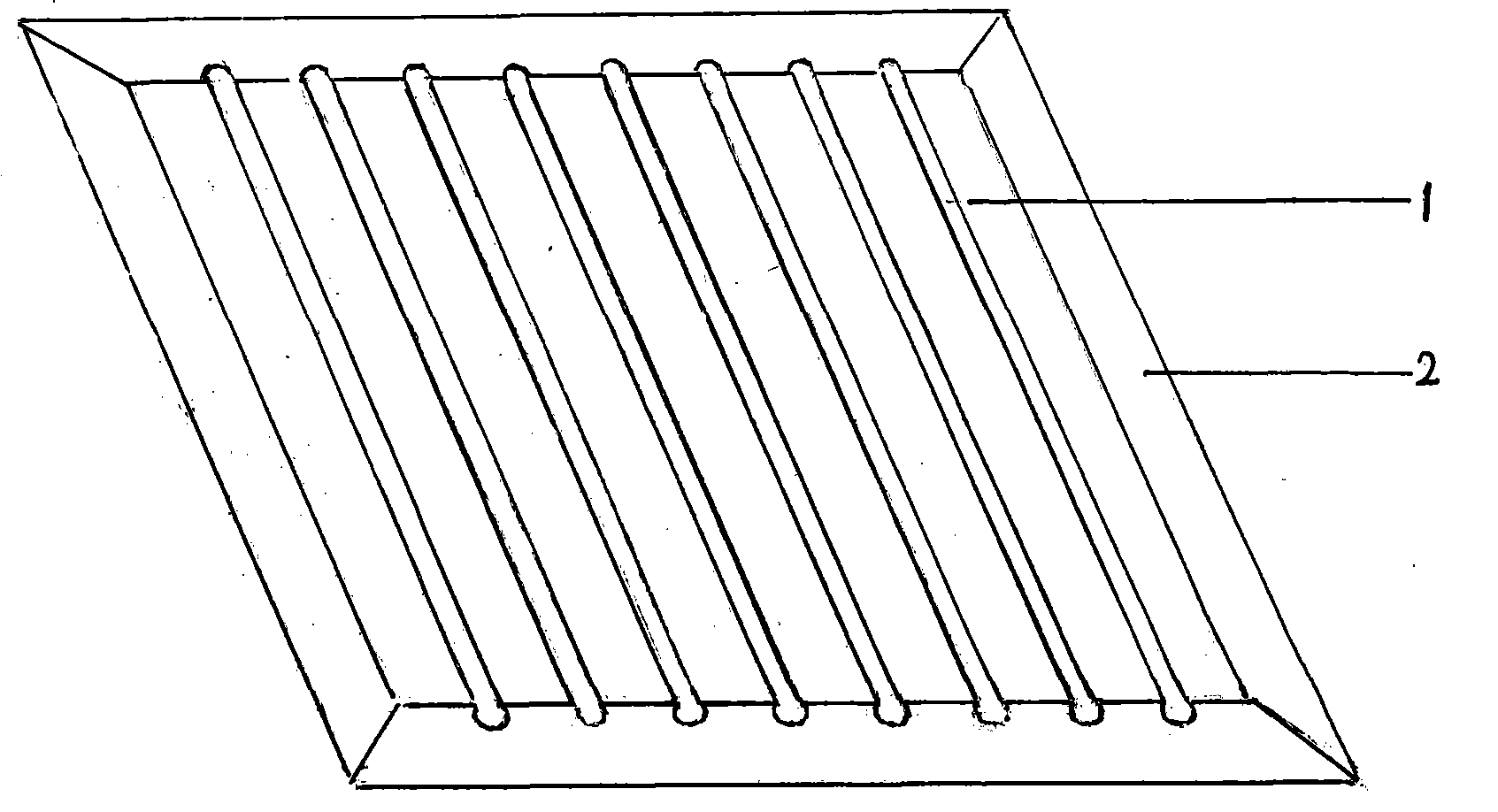

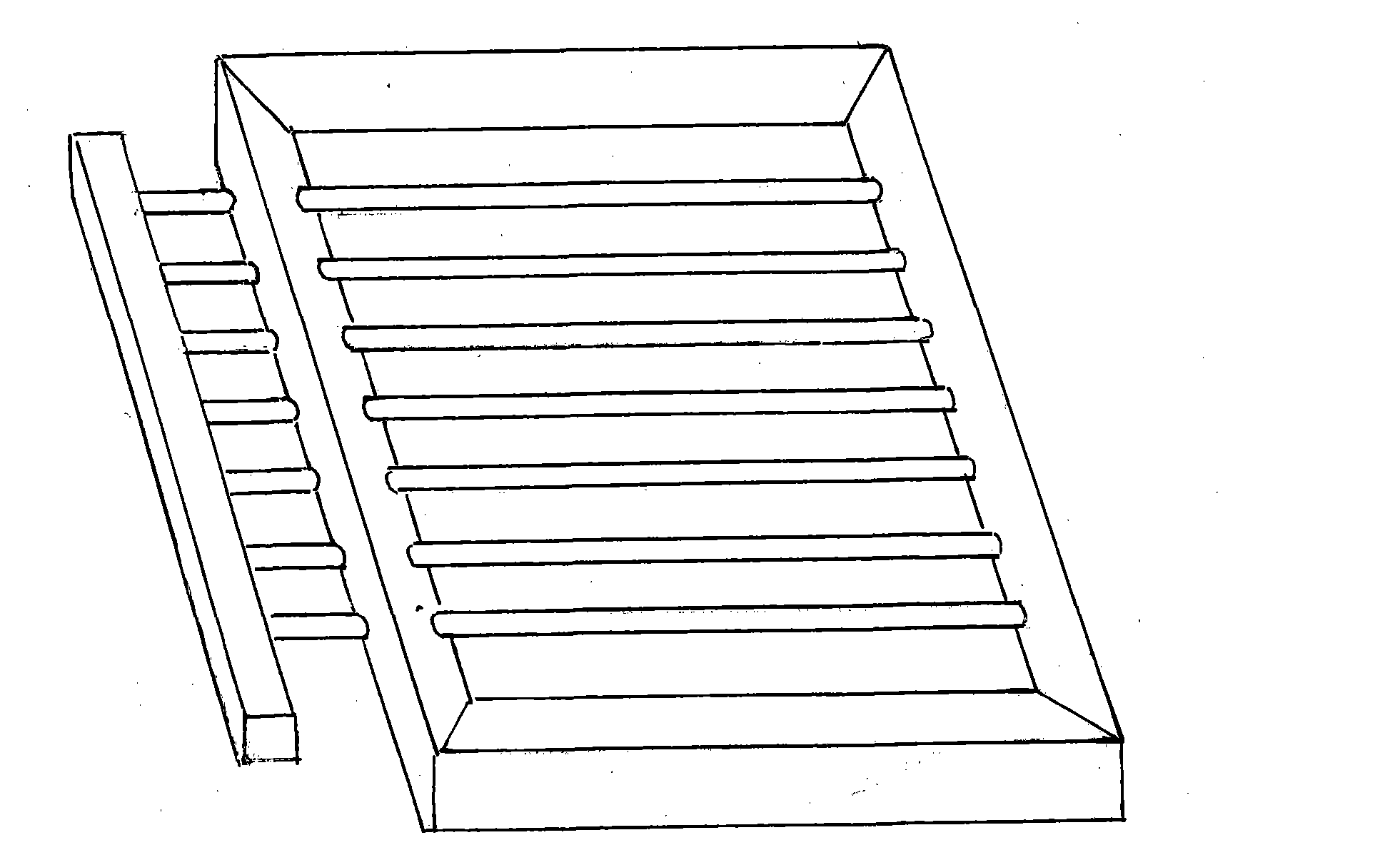

Multifunctional floor tile

InactiveCN104164955AImprove the adhesion firmnessEasy constructionCovering/liningsSingle unit pavingsBrickEngineering

The invention discloses a multifunctional floor tile which is attached to the ground, or a wall or a square column. According to the technical scheme, the functions of a floor tile are increased, and the using effect is improved. The tile is characterized in that no perpendicular angles are formed on the side faces of the periphery and are 40-degree angles inclined inwards, eight cylindrical grooves are formed in the back face and evenly arrayed, in the using process, the tile is convenient to construct, it is avoided that in the heat expansion process, top arching occurs, so that the tile is separated, and due to cement efflorescence, the tile is separated, attachment firmness of the tile is improved, and the multifunctional tile is ideal and easy to use and popularize in quantity.

Owner:刘祖学

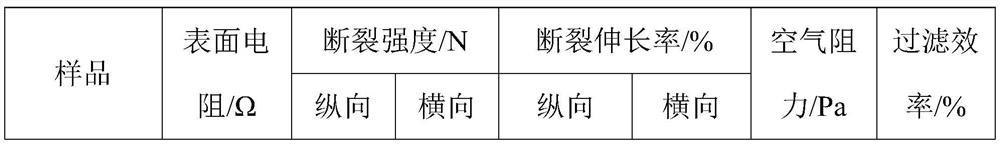

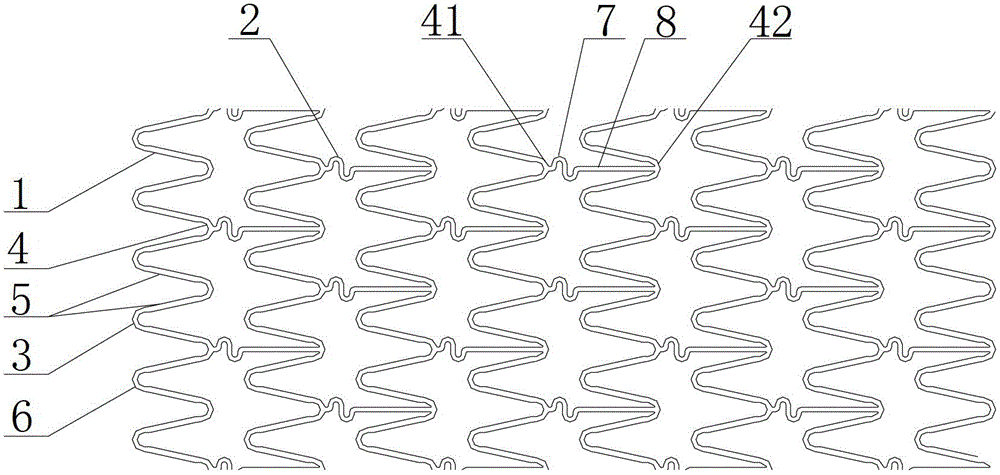

Antistatic filtering material as well as preparation method and application thereof

PendingCN113680138AGood antistatic effectImprove the adhesion firmnessMembrane filtersFiltration separationAntistatic MaterialsCoal dust

The invention provides an antistatic filtering material as well as a preparation method and application thereof. The antistatic filtering material is prepared from the following components: filtering base cloth, graphene and a dispersing agent. The antistatic material provided by the invention has the advantages of permanent antistatic property, extremely low blocking coefficient, excellent mechanical property and high temperature resistance, and can avoid the problem of explosion caused by static electricity and discharge of chemical dust, coal dust and the like when being applied to dust filtration.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Cobalt-chromium alloy arterial stent system with full biodegrade medical coating

ActiveCN103212117BImprove mechanical propertiesGood biocompatibilityStentsSurgeryCoronary arteriesTransport system

The invention provides a cobalt-chromium alloy arterial stent system with a full biodegrade medical coating. The system comprises a transport system and a cobalt-chromium alloy arterial stent which has a full biodegrade medical coating and is sleeved on the transport system. The transport system comprises a push rod, a sacculus and a jacket respectively fixedly connected to both ends of the push rod, and a handle with a Luer joint. A cone-shaped hardened guide wire is arranged at the sacculus end of the push rod. The cobalt-chromium alloy arterial stent with the full biodegrade medical coating is sleeved on the sacculus. The system can avoid damage of the coating to the maximum extent, improve the retaining force between the bracket and the transport system greatly, prevent the probability that the bracket is out of load in the transport process, and reduce the clinical use risk, so that the problems of coronary artery stenosis and restenosis are effectively solved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com