Preparation method of biomass fermentation modified anti-ultraviolet real silk fabric finishing agent

A biomass fermentation and silk fabric technology, which is applied in fiber treatment, animal fiber, light-resistant fiber, etc., can solve the problems of poor affinity, easy agglomeration, and small number of surface active functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

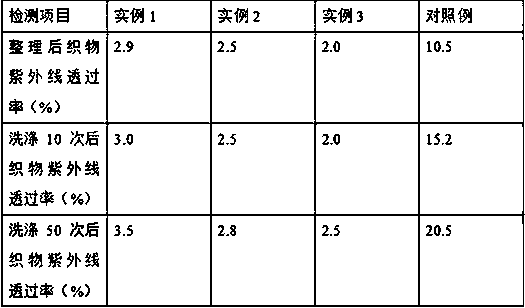

example 1

[0021] According to the mass ratio of 1:3, mix tetra-n-butyl titanate and absolute ethanol, pour it into an ultrasonic oscillator, and process it with ultrasonic oscillation at a frequency of 25kHz for 3min to obtain a titanium source solution. After mixing at 1:3, adjust the pH to 2 with glacial acetic acid to obtain a mixed solution; put the mixed solution into a three-necked flask equipped with a stirrer and a dropping funnel, and then add an equal volume of the mixed solution to the dropping funnel. For the source solution, start the stirrer to stir at a speed of 400r / min, and drop the titanium source solution into the mixed solution drop by drop while stirring, and continue stirring for 40 minutes after the addition of the titanium source solution is completed to obtain a gel solution, which is ready for use; Weigh tea leaves, ginkgo, forsythia and soybeans in a mass ratio of 5:3:2:1 and put them into a tissue grinder to grind for 20 minutes to obtain a grind. Mix the grin...

example 2

[0023]According to the mass ratio of 1:3, mix tetra-n-butyl titanate and absolute ethanol, pour it into an ultrasonic oscillator, and process it with ultrasonic oscillation at a frequency of 28kHz for 4min to obtain a titanium source solution. After mixing 1:3, adjust the pH to 3 with glacial acetic acid to obtain a mixed solution; put the mixed solution into a three-necked flask with a stirrer and a dropping funnel, and then add an equal volume of the mixed solution to the dropping funnel. For the source solution, start the stirrer to stir at a speed of 450r / min, and drop the titanium source solution into the mixed solution drop by drop while stirring, and continue stirring for 45 minutes after the addition of the titanium source solution is completed, to obtain a gel solution, which is ready for use; Weigh tea leaves, ginkgo, forsythia and soybeans in a mass ratio of 5:3:2:1 and put them into a tissue grinder to grind for 25 minutes to obtain a grind, mix the grind and wine i...

example 3

[0025] According to the mass ratio of 1:3, mix tetra-n-butyl titanate and absolute ethanol, pour it into an ultrasonic oscillator, and process it with ultrasonic oscillation at a frequency of 30kHz for 5min to obtain a titanium source solution. After mixing 1:3, adjust the pH to 3 with glacial acetic acid to obtain a mixed solution; put the mixed solution into a three-necked flask with a stirrer and a dropping funnel, and then add an equal volume of the mixed solution to the dropping funnel. For the source solution, start the stirrer to stir at a speed of 500r / min, and drop the titanium source solution into the mixed solution drop by drop while stirring, and continue to stir for 50 minutes after the addition of the titanium source solution is completed, to obtain a gel solution for later use; Weigh tea leaves, ginkgo, forsythia and soybeans in a mass ratio of 5:3:2:1 and put them into a tissue grinder to grind for 30 minutes to obtain a grind. Mix the grind with wine in a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com