Butadiene styrene rubber-based right-angled civil defense door sealing rubber strip and preparation method thereof

A technology for sealing rubber strips and styrene-butadiene rubber, applied in the rubber field, can solve problems such as poor mechanical properties and anti-aging properties, and achieve the effects of excellent mechanical properties, excellent anti-aging properties and reasonable process design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

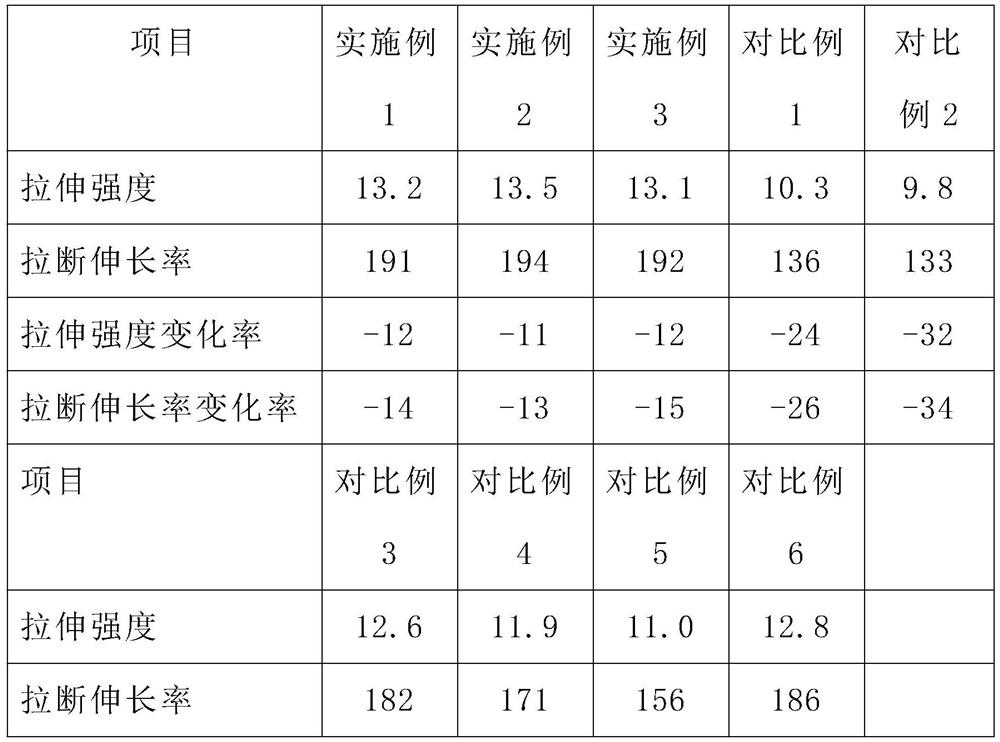

Examples

Embodiment 1

[0048] Step 1: Prepare materials;

[0049] Step 2: Preparation of anti-aging agent:

[0050] Take cerium oxide and stearic acid, dissolve in deionized water, mix and stir for 10 minutes, ultrasonically disperse for 5 minutes, heat up to 90°C, react for 2 hours, cool, filter, and dry to obtain modified cerium oxide;

[0051] Take titanium powder, add hydrogen peroxide, ultrasonically disperse for 5 minutes, stir for 1 hour in an ice-water bath, then continue stirring for 12 hours at 25°C, filter, adjust the pH to neutral, and obtain material A;

[0052] Take aluminum nitrate nonahydrate and magnesium nitrate hexahydrate, dissolve them in absolute ethanol, disperse them ultrasonically for 8 minutes, add sodium hydroxide and methanol mixed solution under nitrogen atmosphere, stir for 10 minutes, then place them in a high-pressure reactor, and react at 150°C for 18 hours. Washing and drying to obtain material B;

[0053] Take material B, dissolve it in deionized water, disperse ...

Embodiment 2

[0063] Step 1: Prepare materials;

[0064] Step 2: Preparation of anti-aging agent:

[0065] Take cerium oxide and stearic acid, dissolve in deionized water, mix and stir for 12 minutes, ultrasonically disperse for 6 minutes, heat up to 95°C, react for 2.5 hours, cool, filter, and dry to obtain modified cerium oxide;

[0066] Take titanium powder, add hydrogen peroxide, ultrasonically disperse for 7 minutes, stir in an ice-water bath for 1.2 hours, then continue stirring at 27°C for 12.5 hours, filter, adjust the pH to neutral, and obtain material A;

[0067] Take aluminum nitrate nonahydrate and magnesium nitrate hexahydrate, dissolve them in absolute ethanol, disperse them ultrasonically for 9 minutes, add sodium hydroxide and methanol mixed solution under nitrogen atmosphere, stir for 13 minutes, then place them in a high-pressure reactor, and react at 155°C for 19 hours. Washing and drying to obtain material B;

[0068] Take material B, dissolve it in deionized water, di...

Embodiment 3

[0078] Step 1: Prepare materials;

[0079] Step 2: Preparation of anti-aging agent:

[0080] Take cerium oxide and stearic acid, dissolve in deionized water, mix and stir for 15 minutes, ultrasonically disperse for 8 minutes, heat up to 100°C, react for 3 hours, cool, filter, and dry to obtain modified cerium oxide;

[0081] Take titanium powder, add it into hydrogen peroxide, ultrasonically disperse for 8 minutes, stir in an ice-water bath for 1.5 hours, then continue stirring at 28°C for 13 hours, filter, adjust the pH to neutral, and obtain material A;

[0082] Take aluminum nitrate nonahydrate and magnesium nitrate hexahydrate, dissolve them in absolute ethanol, disperse them ultrasonically for 10 minutes, add sodium hydroxide and methanol mixed solution under nitrogen atmosphere, stir for 15 minutes, then place them in a high-pressure reactor, and react at 160°C for 20 hours. Washing and drying to obtain material B;

[0083] Take material B, dissolve it in deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com