Nano-wear-resistant polyurethane heel lift composite material and preparation method

A technology of nanomaterials and composite materials, applied in the field of nanometer wear-resistant polyurethane skin composite materials and preparation, can solve the problems of reduced mechanical properties of materials, large specific surface area, easy to agglomerate, etc., to improve dispersion, improve hydrolysis resistance, reduce The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

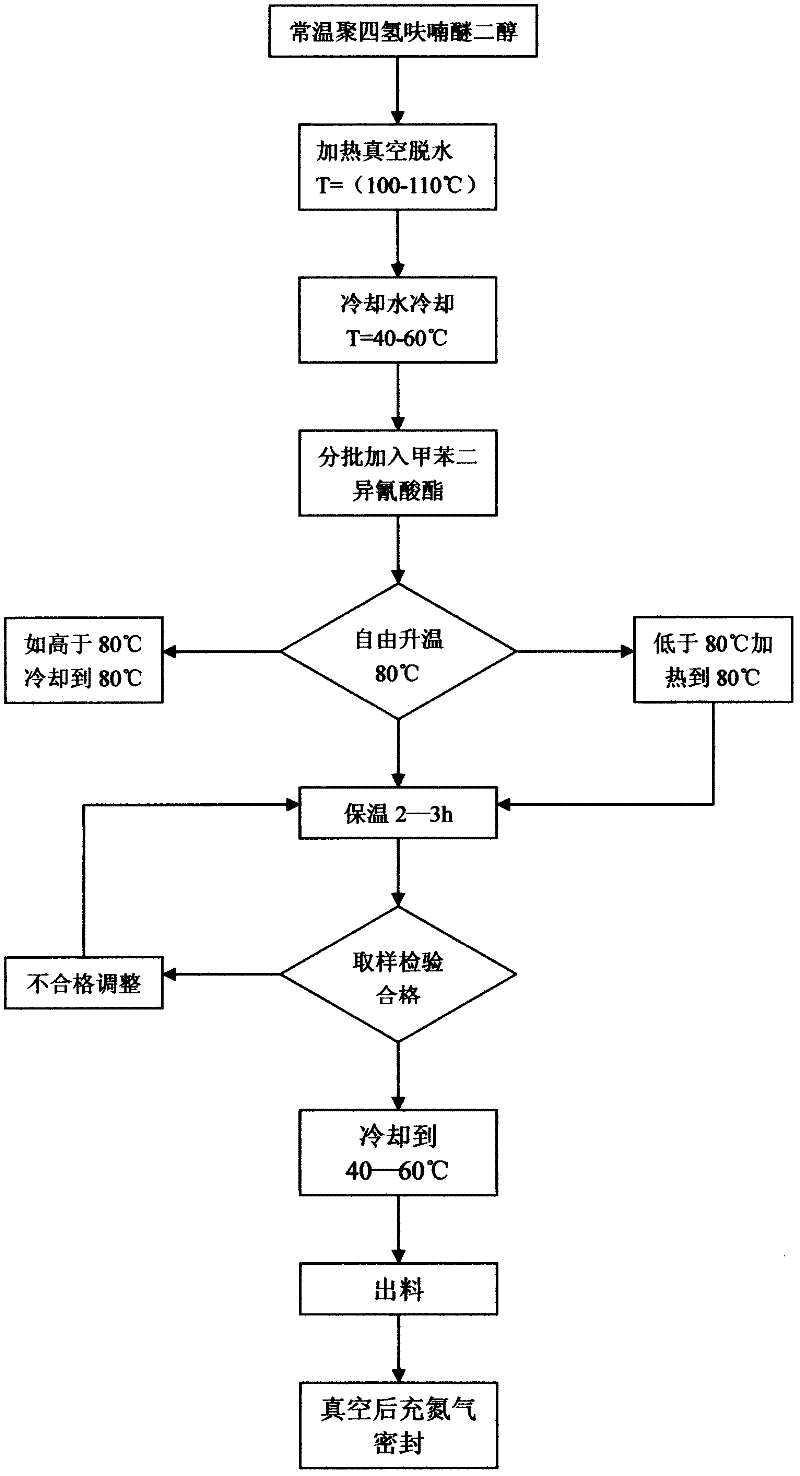

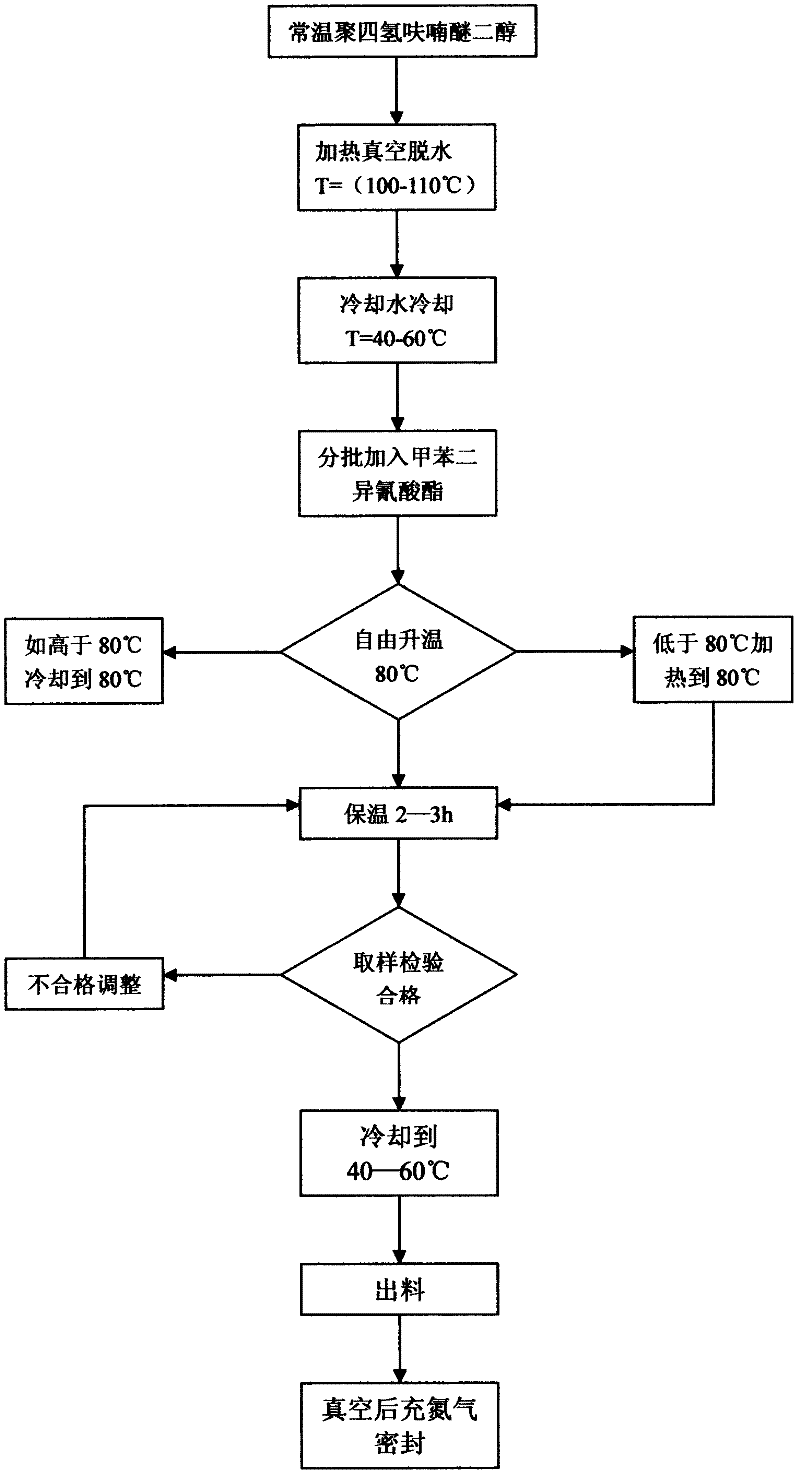

Method used

Image

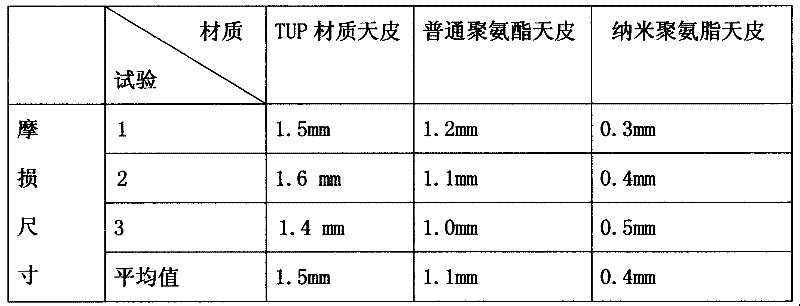

Examples

Embodiment 1

[0095] Example 1: a) Weigh 10kg of the polyurethane skin raw material B component material, add 20g of nano-silicon dioxide and 180g of nano-calcium carbonate composite material, then add silane coupling agent KH-5504g, and heat to 65°C , stirring the mixed material, the reaction time is 2h, and cooling to normal temperature to obtain the B-component material modified by nanomaterials.

[0096] b) Weighing 1kg of nano-alumina and 5kg of ethyl acetate, adding 20g of silane coupling agent KH-550, heating to 65°C, stirring the mixture, reaction time 2h, distilling off the organic solvent under reduced pressure, the modified Drying and grinding the denatured nano-materials to obtain organically modified nano-alumina. Then weigh 10kg of component B of the polyurethane skin raw material, add 200g of modified nano-alumina, heat to 65°C, and stir the mixture for 2 hours to obtain component B modified by nanomaterials.

[0097] c) Measure 100kg of A material layer on the semi-prepolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com