Antistatic graphene material modified fabric and preparation method thereof

A graphene, anti-static technology, applied in the direction of plant fibers, animal fibers, textiles and papermaking, can solve problems such as affecting high efficiency, increasing product production costs, affecting the wearing comfort of fabrics, etc., to achieve excellent antistatic properties, high The effect of adhesion firmness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

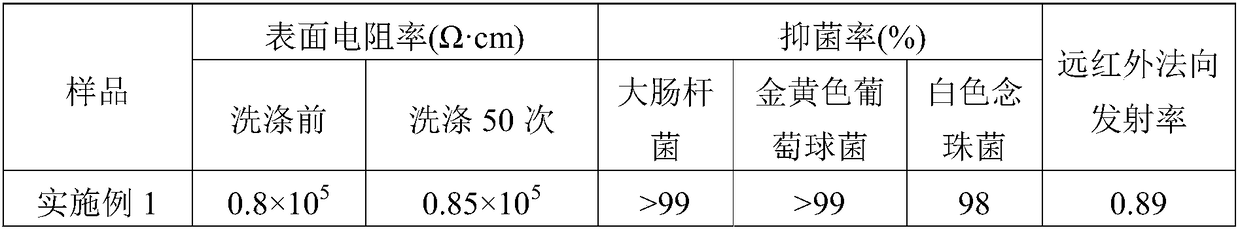

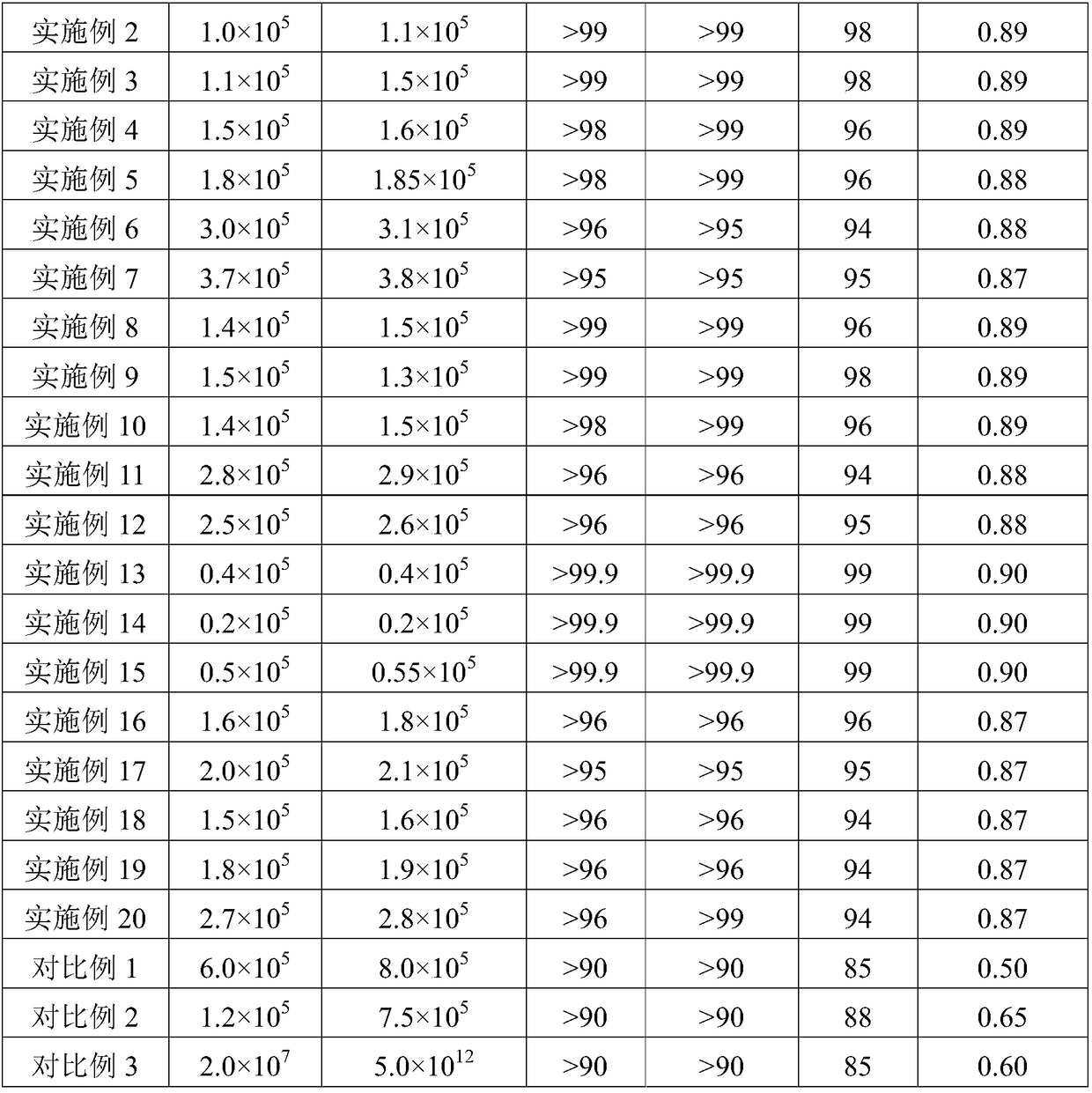

Examples

Embodiment 1

[0069] An antistatic graphene material modified fabric, the fiber is loaded with graphene material and smoothing agent, and the surface resistivity is 1.0×10 6 Below Ω·cm, after washing 50 times, the surface resistivity is still 1.0×10 6 Ω·cm or less.

[0070] Its preparation method comprises the following steps:

[0071] (1') the fabric base cloth is pretreated at 60°C for 20min in a caustic soda solution of 1wt% by concentration, and then washed;

[0072] (1) the graphene material solution that concentration is 2.5wt% is placed in the immersion tank of padding machine, and solution temperature is 30 ℃, and fabric is carried out padding 2 times, and roll temperature is 85 ℃, and dipping speed is 60m / min, control The excess ratio of the fabric was 15%, and then dried at 85° C. to obtain a fabric loaded with graphene material.

[0073] (2) After washing the fabric with water, pad the smoothing agent to obtain a graphene material modified fabric.

[0074] Wherein, fabric bas...

Embodiment 2-3

[0076] The only difference from Example 1 is that in step (1), the scrapping rate is 10% (Example 2) and 20% (Example 3).

Embodiment 4-7

[0078] The only difference with Example 1 is that in step (1), the graphene concentration in the graphene material solution is 1wt% (Example 4), 5wt% (Example 5), 0.1wt% (Example 6) , 6wt% (embodiment 7).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com