Antistatic filtering material as well as preparation method and application thereof

A filter material and antistatic technology, applied in the field of antistatic filter material and its preparation, can solve problems such as failure to reach explosion-proof dust removal control conditions, static electricity cannot be quickly conducted, and static coalescence cannot be eliminated, and achieve excellent antistatic performance. performance, increase the filtration effect, improve the effect of adhesion firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

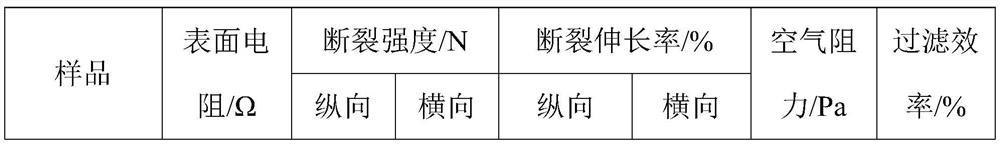

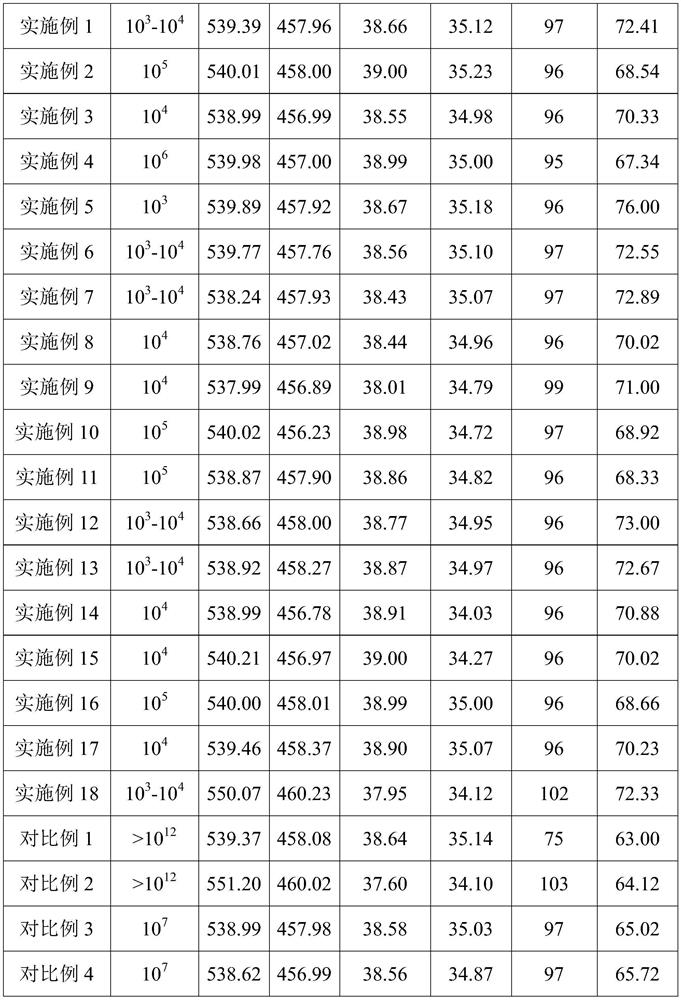

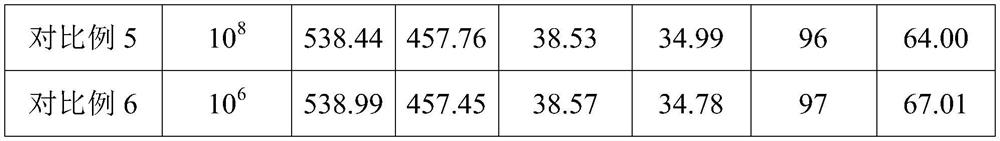

Examples

Embodiment 1

[0049] An antistatic filter cloth, the preparation method is as follows:

[0050] (1) Graphene, dispersant and deionized water are dispersed at 80°C for 3h at a stirring rate of 1000r / min, then filtered through a 200-mesh filter, and the filtrate is obtained to obtain a graphene dispersion;

[0051] Wherein, the size of graphene is 0.2 μm, and dispersant is sodium polystyrene sulfonate, and the mass ratio of graphene and dispersant is 1:0.5, and the concentration of graphene in dispersion liquid is 1wt%;

[0052] (2) The graphene dispersion is placed in the liquid tank of the padding machine, the filter base cloth is dipped and rolled, the liquid-carrying rate is controlled to 100%, the vehicle speed is 30m / min, and then shaped at 150°C to obtain an antistatic filter cloth ;

[0053] Wherein, the filter base fabric is polyester woven fabric, purchased from Renzhong Textile.

Embodiment 2-5

[0055] The difference from Example 1 is that the liquid entrainment rate is controlled to 40% (Example 2), 80% (Example 3), 10% (Example 4), and 150% (Example 5).

Embodiment 6-9

[0057] The difference from Example 1 is that in this example, the size of graphene is 0.1 μm (Example 6), 10 μm (Example 7), 50 nm (Example 8), and 20 μm (Example 9).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com