Buffer sheet used in vacuum chuck that adsorbs object to be processed

A technology of vacuum suction cups and buffer sheets, applied in the field of buffer sheets, can solve the problems of expensive ventilation performance of polyethylene film, insufficient anti-static properties, etc., and achieve excellent anti-static effect and cost reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Various example embodiments will be described more fully hereinafter with reference to the accompanying drawings, in which some example embodiments are shown.

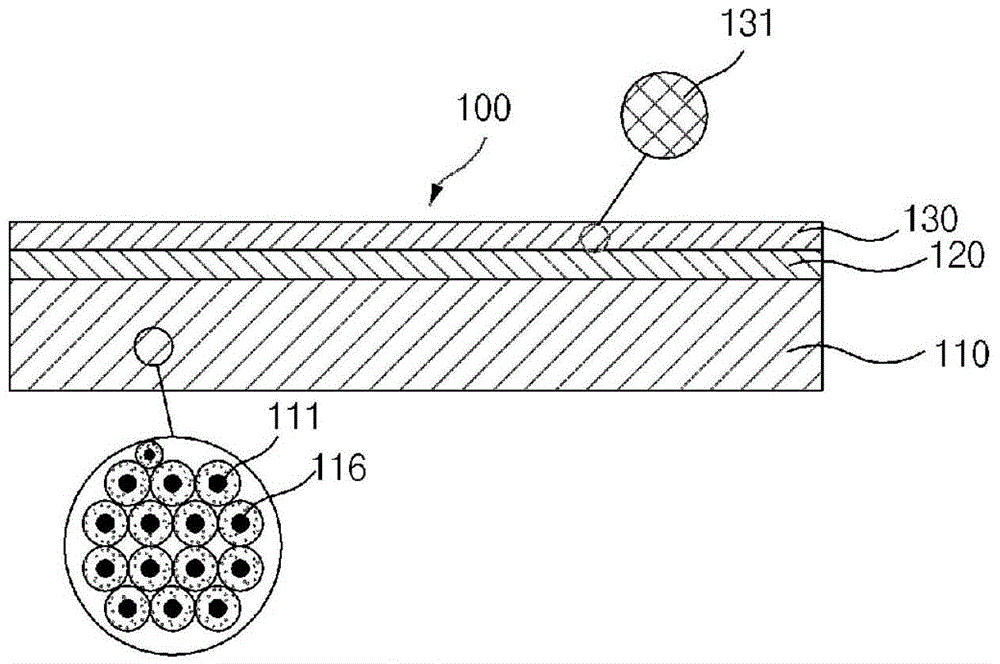

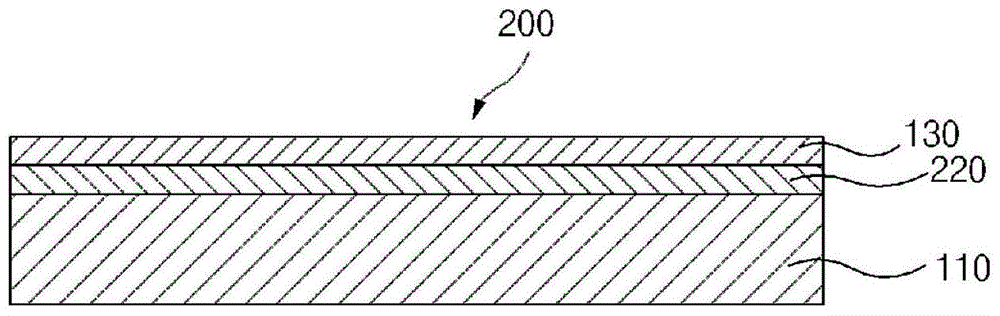

[0027] figure 1 is a cross-sectional view of a buffer sheet 100 of a vacuum chuck for supporting a workpiece according to an exemplary embodiment of the present inventive concept. as in figure 2 As shown in , the buffer sheet 100 includes a non-woven sheet 110 and an ESD coating 130 .

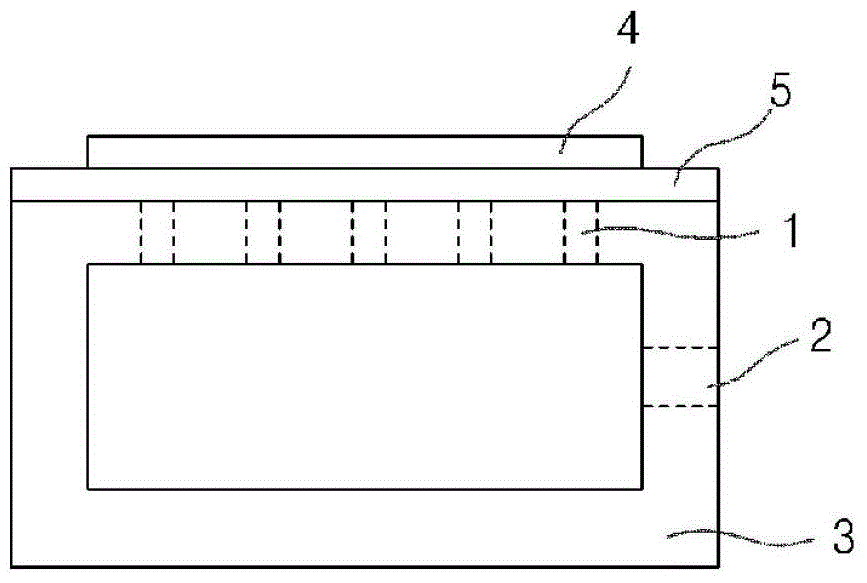

[0028] The buffer sheet 100 is bonded to the upper surface of the vacuum chuck 3 that fixes the work by supporting. The workpiece is set on the buffer sheet 100 . Vacuum chucks exhibit support and fixation in precise cutting operations or precise coating operations for glass substrates or semiconductor wafers used in liquid crystal displays, and in bonding operations for polarizing plates and retardation plates, or those plates with glass substrates Artifact functionality.

[0029] The nonwoven fabric sheet 110 is a mat-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com