Light-colored anti-static silicone rubber and preparation method thereof

An antistatic and silicone rubber technology, applied in the field of light-colored modified antistatic silicone rubber and its preparation, can solve the problems of excessively dark color and poor mechanical properties, and achieve light color, excellent antistatic properties, and good reinforcement. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

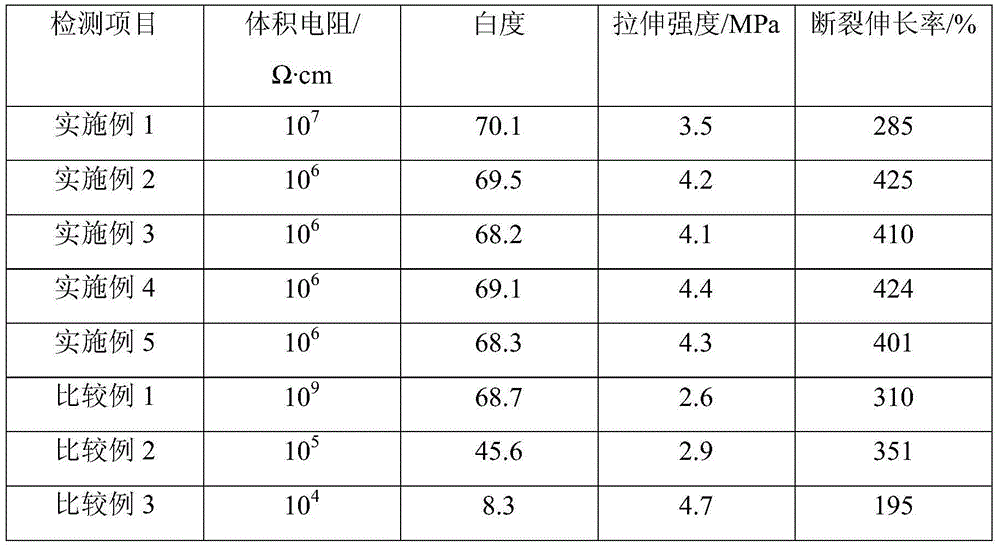

Examples

Embodiment 1

[0023] (1) Add 80.0 g of 2000-mesh flaky silicon micropowder into 60.0 g of water, and ultrasonically disperse it for 10 minutes while stirring to obtain a uniform slurry. After heating up to 60 ° C, add 10 ml of tin-antimony solution dropwise to the slurry while stirring ( SnCl 4 ·5H 2 O and SbCl 3 The mass ratio is 5:1, SnCl 4 ·5H 2 The concentration of O is 0.2g / ml), and then slowly add 1mol / L ammonia solution dropwise until the system pH = 1, after the dropwise addition, keep warm (60°C) for 20min; continue to add to the above slurry 30ml of the above-mentioned tin-antimony solution and 1mol / L ammonia solution, keep the pH of the system at 2, keep warm (60°C) and react for 10min, after the reaction is completed, filter the product with suction, wash, dry, and pulverize; then calcinate at 500°C for 3h , that is, the ATO / silica powder conductive composite material;

[0024] (2) Preparation steps of antistatic rubber: Add 100 g of raw methyl silicone rubber to the intern...

Embodiment 2

[0026] (1) Add 80.0 g of 10,000-mesh flaky silicon micropowder into 100.0 g of water, and ultrasonically disperse it for 15 minutes while stirring to obtain a uniform slurry. After heating up to 70 ° C, add 40 ml of tin-antimony solution dropwise to the slurry while stirring ( SnCl 4 ·5H 2 O and SbCl 3 The mass ratio is 8:1, SnCl 4 ·5H 2 The concentration of O is 0.4g / ml), and then slowly add 2mol / L NaOH solution dropwise until the system pH=1.5, after the dropwise addition is completed, keep warm (70°C) and react for 25min; continue to add the above-mentioned 120ml of tin antimony solution and 2mol / L NaOH solution, keep the system pH=3, keep warm (70°C) and react for 20min, after the reaction is completed, filter the product with suction, wash, dry and pulverize; then calcinate at 600°C for 2h, That is, the ATO / silica powder conductive composite material is obtained;

[0027] (2) Antistatic rubber preparation steps: Add 100 g of methyl vinyl silicone rubber raw rubber to...

Embodiment 3

[0029] (1) Add 80.0 g of 11000-mesh flaky silicon micropowder into 120.0 g of water, and ultrasonically disperse it for 20 minutes while stirring to obtain a uniform slurry. After heating up to 70 ° C, add 47 ml of tin-antimony solution dropwise to the slurry while stirring ( SnCl 4 ·5H 2 O and SbCl 3 The mass ratio of SnCl is 12.5:1, SnCl 4 ·5H 2 The concentration of O is 0.45g / ml), then slowly add 3.5mol / L NaOH solution dropwise until the system pH=2, keep warm (70°C) and react for 40min after the dropwise addition; continue to drip rapidly into the above slurry Add 140ml of the above-mentioned tin-antimony solution and 3.5mol / L NaOH solution, keep the pH of the system at 3.5, keep warm (70°C) and react for 25min, after the reaction is completed, filter the product with suction, wash, dry and pulverize; Calcined for 2 hours, the ATO / silicon powder conductive composite material is obtained;

[0030](2) Preparation steps of antistatic rubber: Add 100 g of raw methyl vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com