A kind of composite filter material for biological soil deodorization and its application

A composite filter material and bio-soil technology, applied in the direction of microorganisms, microorganism-based methods, biochemical equipment and methods, etc., can solve the problem of outage of biological soil deodorization system, poor secondary input effect of the system, and low microbial adsorption, etc. Problems, to achieve the effect of rapid secondary operation, high adhesion firmness, and high microbial abundance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Citrate pylorgi ZT-S5 was cultured by culture fluid, and the concentration of CFU values of 1.1 × 109 were obtained by 1.1 × 109 concentration CFU value of 1.1 × 109;

[0021] Pour the Citrogen pylori ZT-S5 bacterial solution into a self-made reactor of 1 cubic meter;

[0022] Pour 400L diameter of 3-5 mm wood base carbonized wood;

[0023] Open the bottom of the reactor, ventilation for 2 hours, stop the intake air standing for 2 hours, the ventilation is 2 hours, stop the intake of allowing for 2 hours, pull out the pull-free screen box, naturally drained water, the wood-based granules Carbon carrier solidification microbial filler about 400L;

[0024] Pour the 400L wood-based granulated carbon carrier into 1 cubic meter diameter 1-3mm, about 30% of the porosity, and the specific surface area of 8 m2 / g, the mixture is stirred, One biological soil deodorization is composite filter material.

Embodiment 2

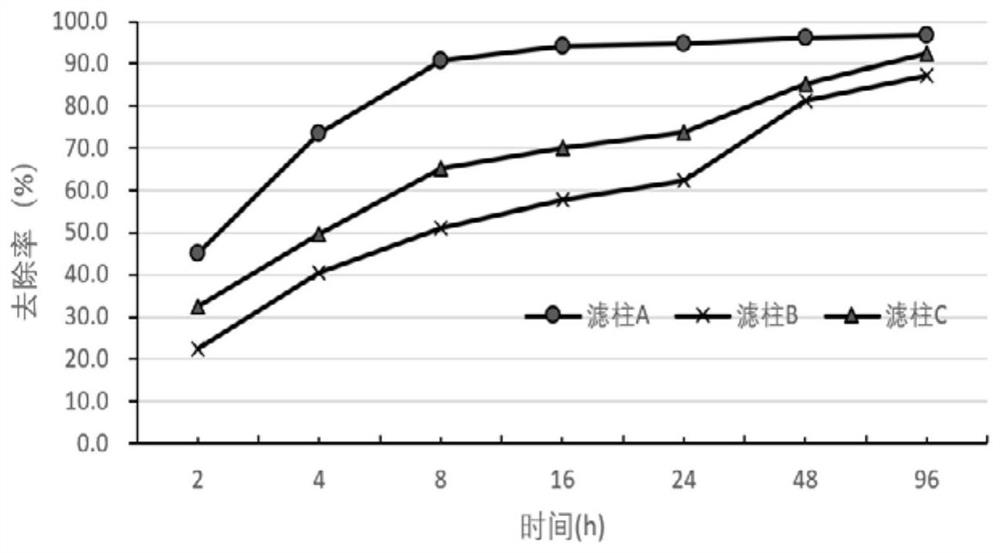

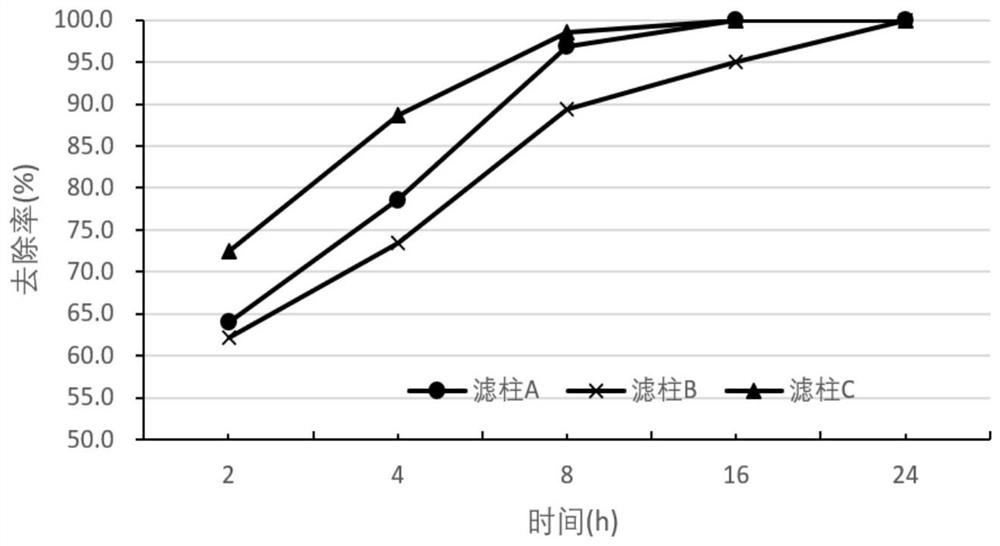

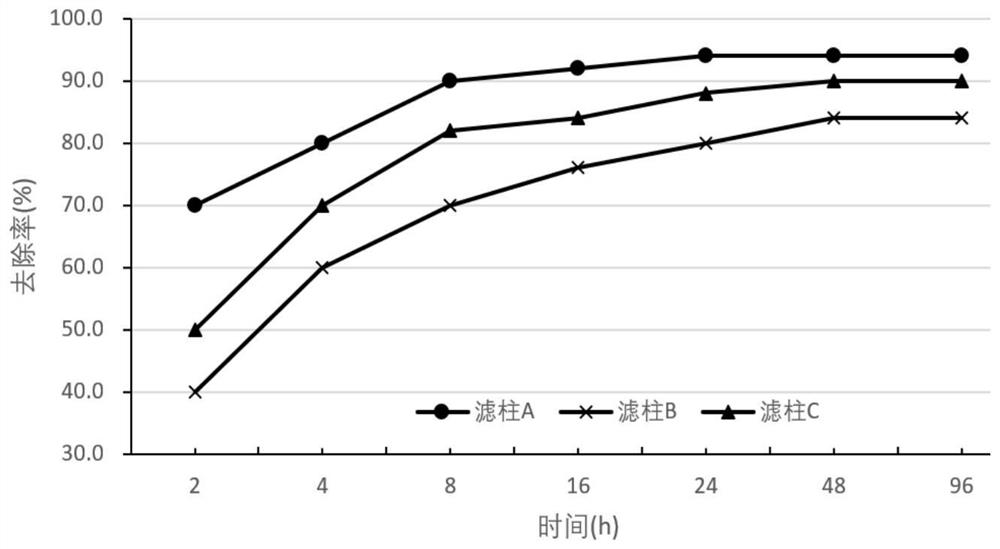

[0026] The three diameter of 20 cm, a height of 100 cm is produced, and a biological soil deodorizing composite filter material (filter column A), volcanic filter (filter column B), a volcanic filter material (filter column B), and volcanic filtration filter (filter column B). Bamboo charcoal filter material (filter column C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com