A kind of corrosion-resistant spectacle frame and its processing technology

A glasses frame, corrosion-resistant technology, used in glasses/goggles, anti-corrosion coatings, instruments, etc., can solve problems such as rust and poor corrosion resistance, improve stability, improve coating adhesion, and improve corrosion resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

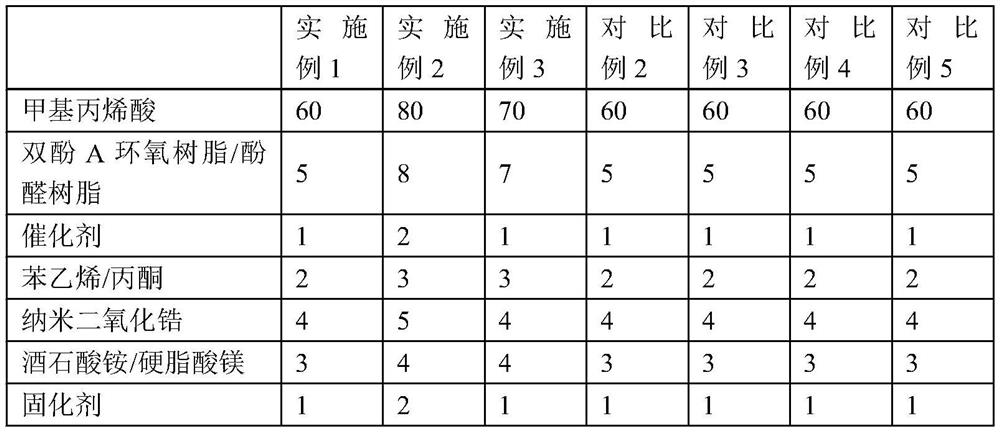

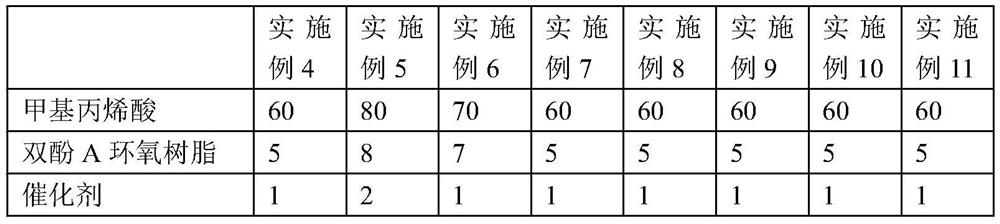

Embodiment 1

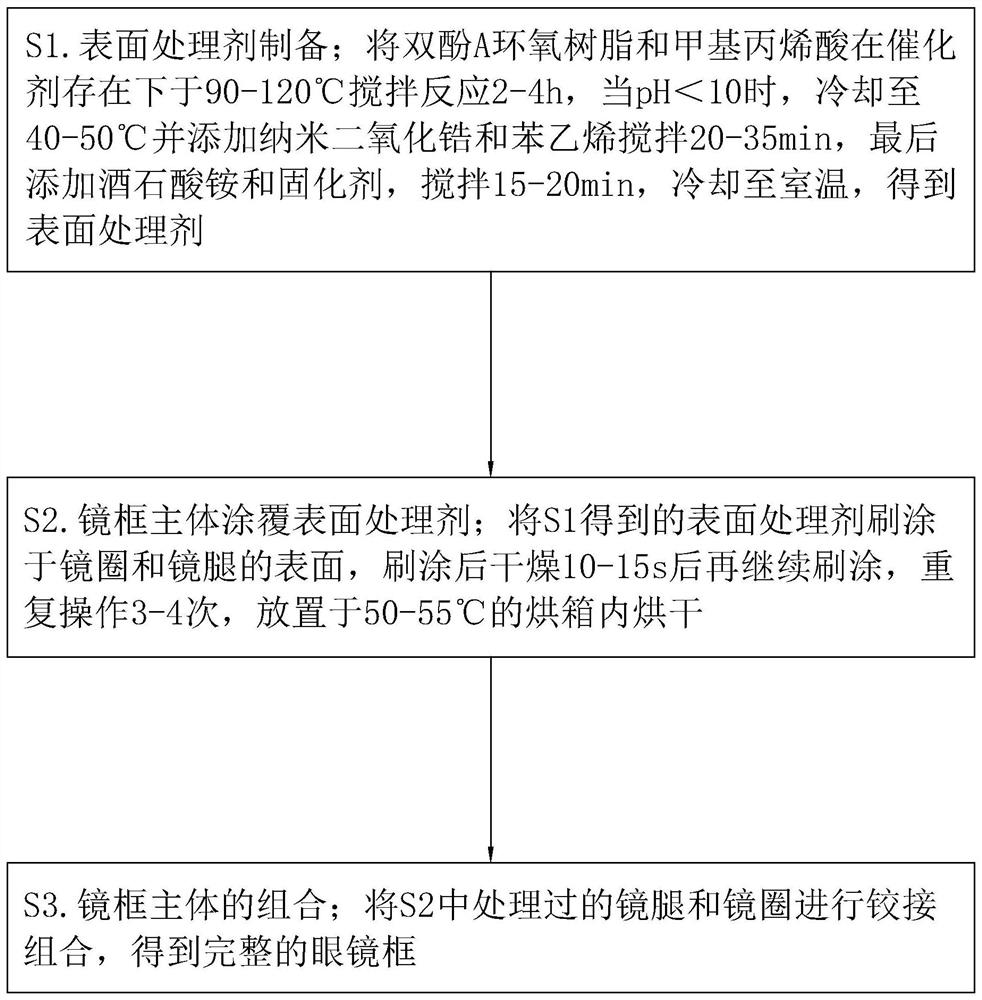

[0041] This application discloses a corrosion-resistant spectacle frame and its processing technology, referring to figure 1 , the processing technology includes the following steps:

[0042] S1. Preparation of surface treatment agent: Bisphenol A epoxy resin and methacrylic acid were stirred and reacted at 90°C for 2h in the presence of a catalyst. When the pH<10, cooled to 40°C and added nano-sized zirconium dioxide and styrene and stirred for 20min , and finally add ammonium tartrate and curing agent, stir for 15 minutes, and cool to room temperature to obtain a surface treatment agent;

[0043] S2. Coat the surface treatment agent on the main body of the frame; brush the surface treatment agent obtained in S1 on the surface of the mirror ring and temple, and then continue to brush after drying for 10 seconds. Repeat the operation 3 times and place it in an oven at 50°C Internal drying;

[0044] S3. Combination of the main body of the spectacle frame; hinge and combine th...

Embodiment 2

[0047] This application discloses a corrosion-resistant spectacle frame and its processing technology, referring to figure 1 , the processing technology includes the following steps:

[0048] S1. Preparation of surface treatment agent: Bisphenol A epoxy resin and methacrylic acid were stirred and reacted at 120°C for 4h in the presence of a catalyst. When pH<10, cooled to 50°C and added nano-zirconia and styrene and stirred for 35min , and finally add ammonium tartrate and curing agent, stir for 20 minutes, and cool to room temperature to obtain a surface treatment agent;

[0049] S2. Coat the surface treatment agent on the main body of the mirror frame; brush the surface treatment agent obtained in S1 on the surface of the mirror ring and temples, dry for 15 seconds after brushing and then continue brushing, repeat the operation 4 times, and place in an oven at 55 °C Internal drying;

[0050] S3. Combination of the main body of the spectacle frame; hinge and combine the tem...

Embodiment 3

[0053] This application discloses a corrosion-resistant spectacle frame and its processing technology, referring to figure 1 , the processing technology includes the following steps:

[0054] S1. Preparation of surface treatment agent: Bisphenol A epoxy resin and methacrylic acid were stirred and reacted at 100°C for 3h in the presence of a catalyst. When the pH<10, cooled to 45°C and added nano-zirconia and styrene and stirred for 30min , and finally add ammonium tartrate and curing agent, stir for 18 minutes, and cool to room temperature to obtain a surface treatment agent;

[0055] S2. Coat the surface treatment agent on the main body of the mirror frame; brush the surface treatment agent obtained in S1 on the surface of the mirror ring and temples, dry for 13 seconds after brushing, and then continue brushing, repeat the operation 4 times, and place in an oven at 52°C Internal drying;

[0056]S3. Combination of the main body of the spectacle frame; hinge and combine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com