Polysulfonamide inflaming-retarding comfortable elastic knitted plus material and preparation method thereof

A technology of knitted fabrics and polysulfone fibers, which is applied in the field of knitted fabrics production, can solve the problems of not being washable, not firmly attached, and stiff fabrics, etc., and achieves the effects of strong environmental protection, superior color fastness, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 The preparation of a sulfonamide flame-retardant comfortable elastic knitted fabric comprises the following steps:

[0028] (1) Preparation of functional flame-retardant yarn: polyamide fiber with a number of 100tex is used as the first yarn, and the core-spun yarn of polyamide fiber coated with sulfonamide fiber is the first yarn. 50% of the total weight of the first yarn; with 20tex acrylic fiber and polytetrafluoroethylene fiber and twist, and then use two-way coating on the spinning machine and Tencel fiber to wrap and spin to get the second yarn ; the fineness of the second yarn is finer than that of the first yarn, the first yarn is a denier number of 300D, and the second yarn has a yarn fineness of about 54 / 2; with Cationic modified polyester low elastic yarn is the third yarn;

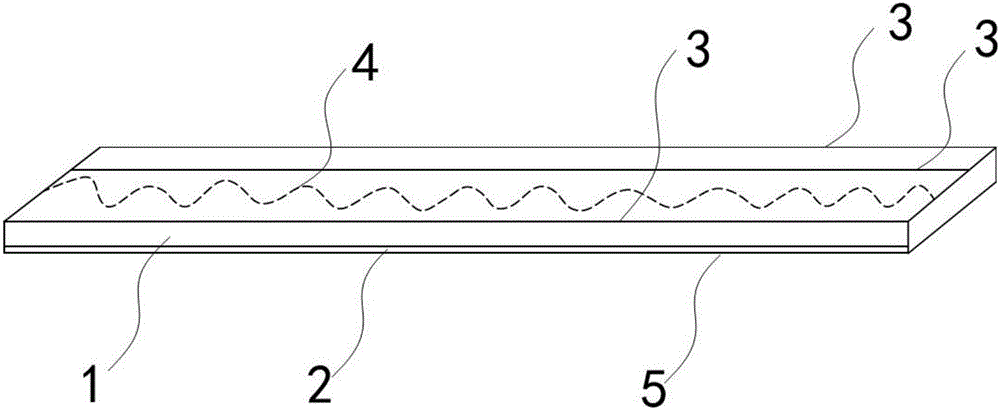

[0029] (2) Weaving: the first yarn, the second yarn and the third yarn after processing are woven into a base fabric by a knitting process, such as figure 1 As shown, the bas...

Embodiment 2

[0032] Example 2 The preparation of the flame-retardant and comfortable elastic knitted fabric of sulfonamide comprises the following steps:

[0033] (1) Preparation of functional flame-retardant yarn: polyamide fiber with a number of 150tex is used as the first yarn, and the core-spun yarn of polyamide fiber coated with sulfonamide fiber is the first yarn. 60% of the total weight of the first yarn; with 30tex acrylic fiber and polytetrafluoroethylene fiber and twist, and then use two-way coating on the spinning machine and viscose fiber to wrap and spin to get the second yarn ; the fineness of the second yarn is finer than that of the first yarn, the first yarn is a denier of 300D, and the second yarn has a yarn fineness of about 18 / 2.

[0034] (2) Weaving: the first yarn, the second yarn and the third yarn after processing are woven into a base fabric by a knitting process, such as figure 1 As shown, the base fabric includes a backing layer 2 and a braided layer 1, the back...

Embodiment 3

[0037] Example 3 The preparation of the flame-retardant and comfortable elastic knitted fabric of sulfonamide comprises the following steps:

[0038] (1) Preparation of functional flame-retardant yarn: polyamide fiber with a number of 120tex is used as the first yarn, and the core-spun yarn of polyamide fiber coated with sulfonamide fiber is the first yarn. 60% of the total weight of the first yarn; with 30tex acrylic fiber and polytetrafluoroethylene fiber and twist, and then use two-way coating on the spinning machine and lyocell fiber to wrap and spin to get the second yarn thread; the second yarn has a finer count than the first yarn, the first yarn has a denier of 300D, and the second yarn has a yarn count of about 32 / 2.

[0039] (2) Weaving: the first yarn, the second yarn and the third yarn after processing are woven into a base fabric by a knitting process, such as figure 1 As shown, the base fabric includes a backing layer 2 and a braided layer 1, the backing layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com