Low-friction coefficient high-resistance aluminized film and preparation method thereof

A low friction coefficient, high barrier technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of heat seal strength (weak barrier properties, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

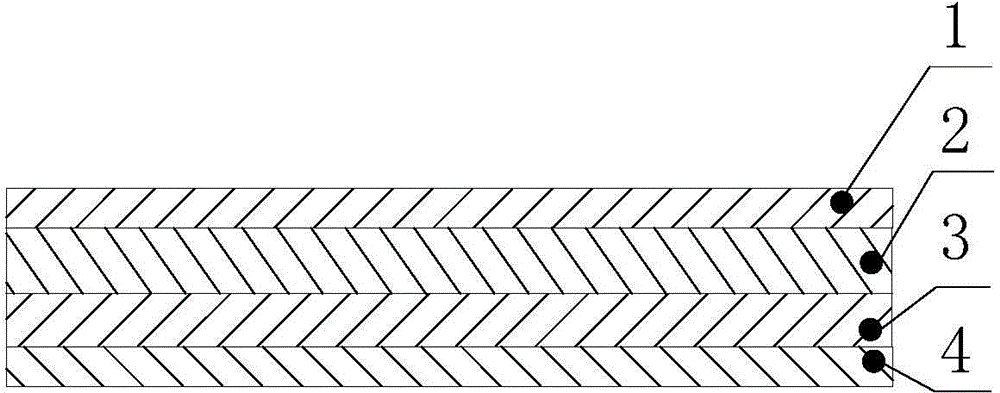

[0021] Such as figure 1 As shown, a low-friction coefficient high-barrier aluminum-coated film is formed by four-layer co-extrusion of a heat-sealing layer 1, a first core layer 2, a second core layer 3, and an aluminum-coated layer 4; The mass percentages of the heat-sealing layer 1, the first core layer 2, the second core layer 3, and the aluminum plating layer 4 are respectively: 21%, 30%, 30%, and 19%;

[0022] The material of the heat-sealing layer is formed by mixing ternary random copolymer polypropylene (PP) resin [ternary random copolymer resin 750M] and a modifier, and the amount of the modifier added is ternary random copolymer 10-15% of the mass of propylene (PP) resin;

[0023] The material of the first core layer adopts polypropylene resin (containing few low-molecular precipitates), and because the precipitates are few, the maintenance of the corona value of the base film and the adhesion of the follow-up aluminum layer have played a better effect;

[0024] Th...

Embodiment 2

[0038] Such as figure 1 As shown, it is basically the same as Example 1, except that: the material of the aluminum layer adopts ethylene-vinyl acetate (EVA) copolymer resin.

[0039] The advantages of similar products in the market are as follows: the invention has good flatness, high gloss, high heat-sealing strength and low coefficient of friction. Uniform aluminum plating, high adhesion, excellent barrier after aluminum plating, high brightness. The heat seal strength of similar products in the market is 8N / 108 degrees, and the product of the present invention is 12N / 104 degrees. The coefficient of friction of similar products in the market is 0.6-0.8, and that of the product of the present invention is 0.3-0.4.

Embodiment 3

[0041] Such as figure 1 As shown, it is basically the same as Example 1, except that the modifier is Exxon FL3980.

[0042] The advantages of similar products in the market are as follows: the invention has good flatness, high gloss, high heat-sealing strength and low coefficient of friction. Uniform aluminum plating, high adhesion, excellent barrier after aluminum plating, high brightness. The heat seal strength of similar products in the market is 8N / 108 degrees, and the product of the present invention is 12N / 104 degrees. The coefficient of friction of similar products in the market is 0.6-0.8, and that of the product of the present invention is 0.3-0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com