Aramid fiber dyeing process and system

A dyeing system and technology of aramid fiber, applied in the field of aramid fiber dyeing process and system, can solve the problems of affecting the aesthetics of the product, poor adhesion effect, de-dyeing, fading, etc., to achieve good dyeing effect, improve full contact, improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

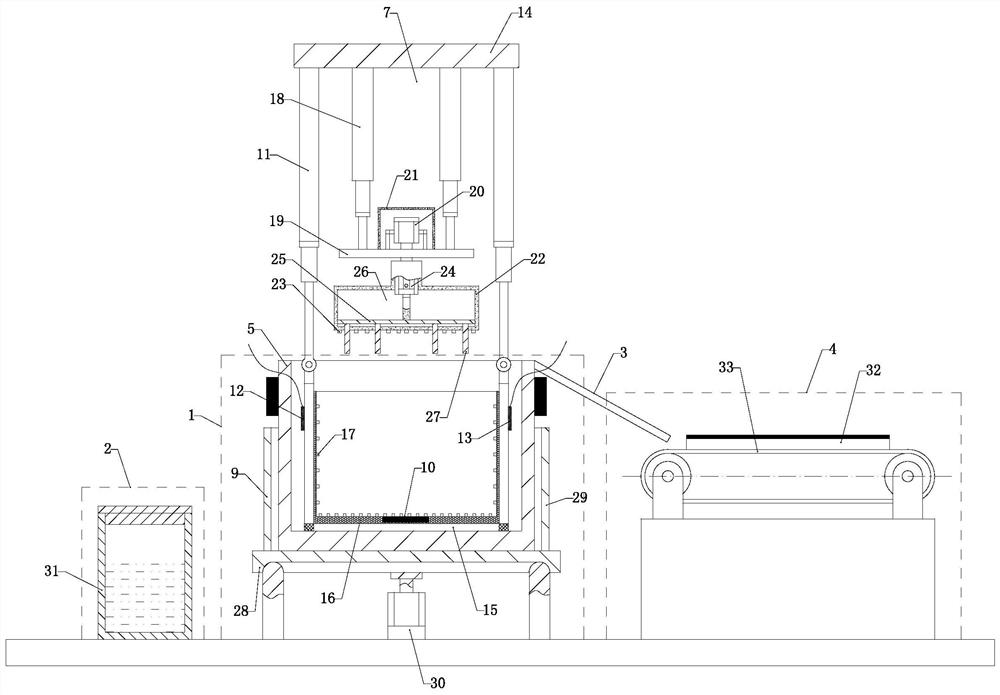

[0036] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

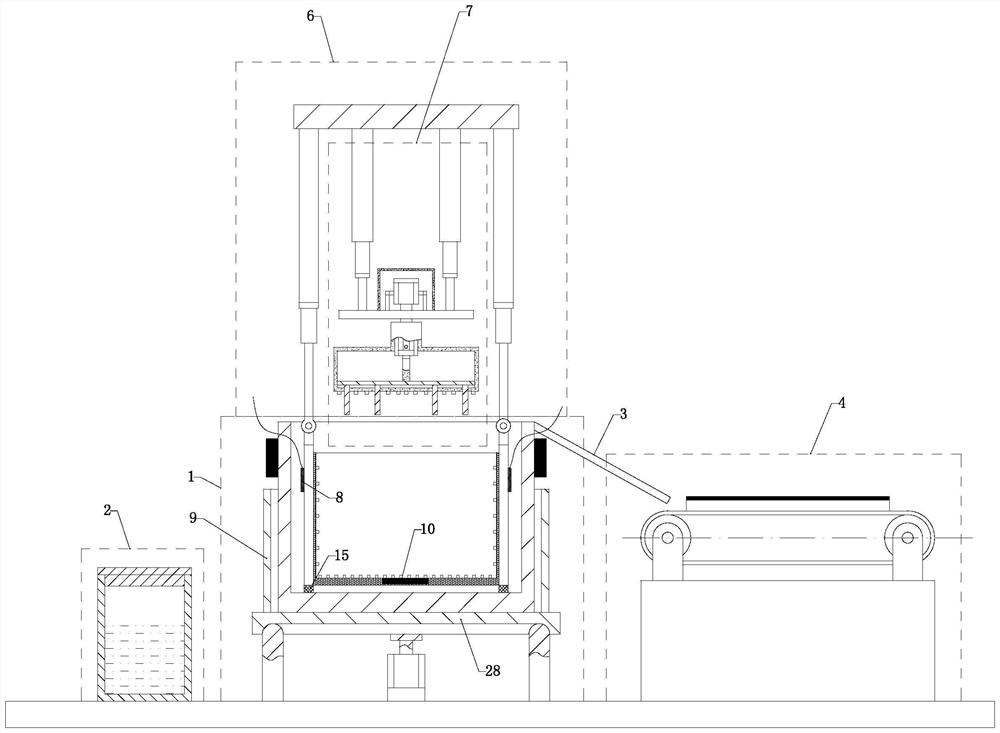

[0037] Such as Figure 1-2 Shown in, a kind of aramid fiber dyeing process comprises the following steps:

[0038] S1. Load the aramid fiber materials to be dyed into the empty space of the aramid fiber dyeing system in turn, and prepare the materials;

[0039] S2. Place the above-mentioned aramid fiber that has been prepared in the insulating inner cylinder in the dyeing bin 5 of the aramid dyeing system, open the cathode plate 12 and the anode plate 13, and control the main scrubbing motor 20 to move to an appropriate position, and then carry out Initially ionize and keep the main scrubbing motor 20 stirring; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com