Method for preparing flexography water-based ink for plastic film

A water-based ink and flexographic printing technology, which is applied in ink, applications, household appliances, etc., can solve the problems of water-based inks such as low adhesion, small solubility parameters, and insufficient adhesion fastness, and achieve strong affinity, good compatibility, Effect of increasing adhesion and adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

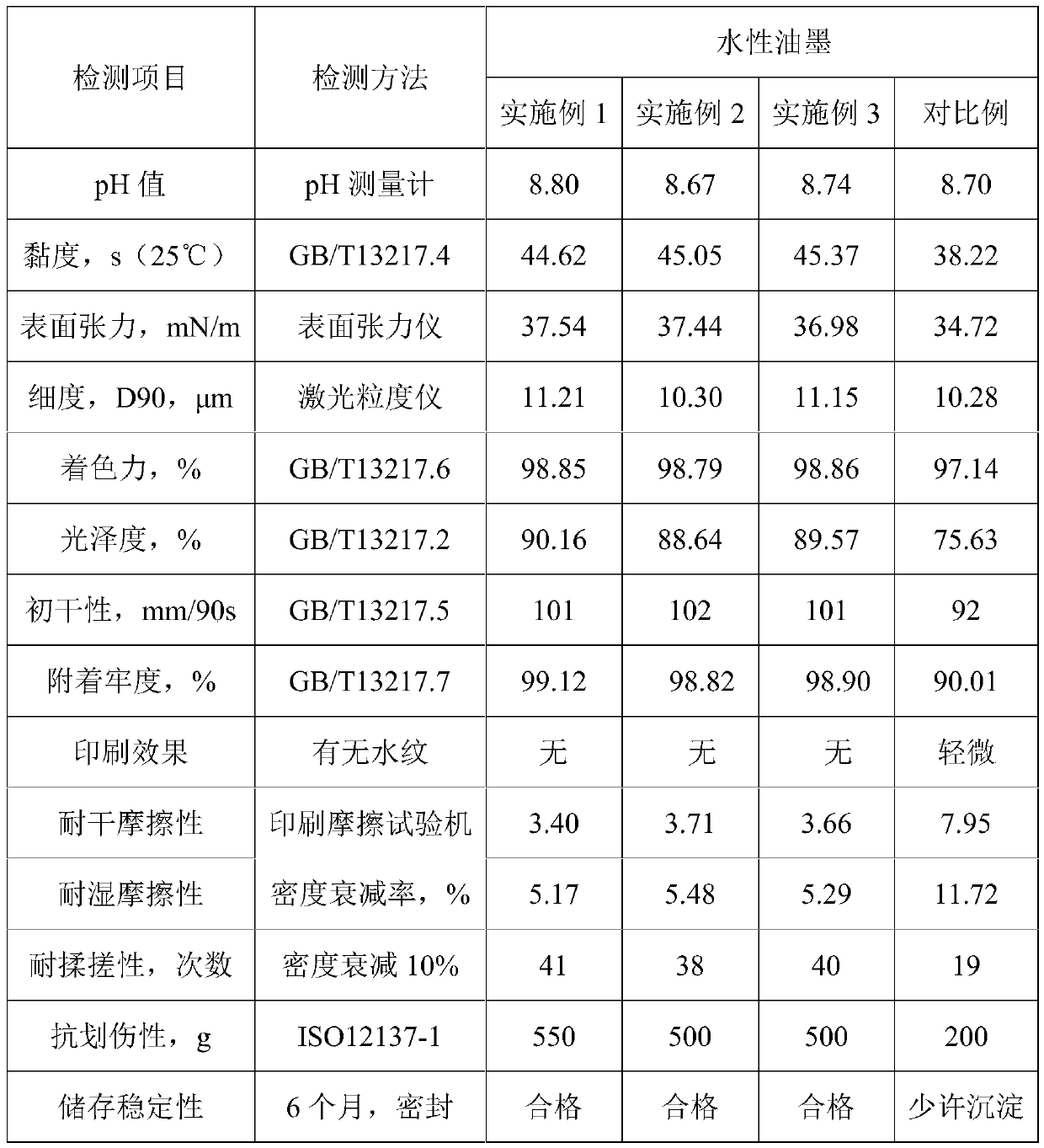

Examples

Embodiment 1

[0033] The flexographic printing water-based ink for plastic film of the present embodiment is made up of the component of following mass percent: water-based acrylate emulsion 45%, water-based dicyclopentadiene acrylate emulsion 12%, pigment 17%, defoamer 0.5%, 0.9% dispersant, 0.7% substrate wetting agent, 0.8% leveling agent, 0.8% fumed silicon dioxide, the balance is water and pH stabilizer triethanolamine, and the pH value of the water-based ink is 8.5-9.0.

[0034] The preparation method of the flexographic printing water-based ink for the plastic film of the present embodiment may further comprise the steps:

[0035] 1) Preparation of water-based acrylate emulsion:

[0036] Take the monomer raw materials methyl methacrylate, butyl acrylate, acrylic acid, and hydroxypropyl acrylate and mix them uniformly according to the ratio of 25:13:1.5:0.5 by mass to obtain a monomer mixture;

[0037] Add 1 / 10 monomer mixture, first emulsifier and buffer sodium bicarbonate into wate...

Embodiment 2

[0045] The flexographic printing water-based ink for plastic films of the present embodiment is composed of the following components in mass percentage: 48% of water-based acrylate emulsion, 10% of water-based dicyclopentadiene acrylate emulsion, 17% of pigment, 0.6% of defoamer, Dispersant 1.0%, substrate wetting agent 0.6%, leveling agent 0.6%, fumed silicon dioxide 0.9%, the balance is water and pH stabilizer triethanolamine, and the pH value of the water-based ink is 8.5-9.0.

[0046] The preparation method of the flexographic printing water-based ink for the plastic film of the present embodiment may further comprise the steps:

[0047] 1) Preparation of water-based acrylate emulsion:

[0048] Take monomer raw materials methyl methacrylate, butyl acrylate, acrylic acid, and hydroxypropyl acrylate and mix them uniformly according to the ratio of 25:13.5:1.7:0.8 in mass ratio to obtain a monomer mixture;

[0049] Add 1 / 10 monomer mixture, first emulsifier and buffer sodium...

Embodiment 3

[0057] The flexographic printing water-based ink for plastic film of the present embodiment is made up of the component of following mass percent: water-based acrylate emulsion 46%, water-based dicyclopentadiene acrylate emulsion 11%, pigment 17%, defoamer 0.7%, 0.8% dispersant, 0.8% substrate wetting agent, 0.5% leveling agent, 1.0% fumed silicon dioxide, the balance is water and pH stabilizer triethanolamine, and the pH value of the water-based ink is 8.5-9.0.

[0058] The preparation method of the flexographic printing water-based ink for the plastic film of the present embodiment may further comprise the steps:

[0059] 1) Preparation of water-based acrylate emulsion:

[0060] Take the monomer raw materials methyl methacrylate, butyl acrylate, acrylic acid, and hydroxypropyl acrylate and mix them uniformly according to the ratio of 25:14:2.0:1.0 by mass to obtain a monomer mixture;

[0061] Add 1 / 10 monomer mixture, first emulsifier and buffer sodium bicarbonate into wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| freshness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com