Oil sludge treatment conditioning additive, preparation method and use method thereof

An additive and sludge technology, applied in sludge treatment, immiscible solvent sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution, low sludge treatment efficiency, etc. effect, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

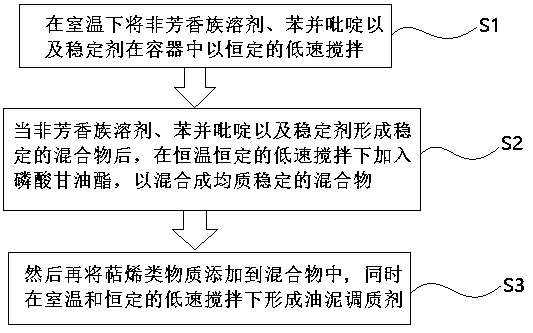

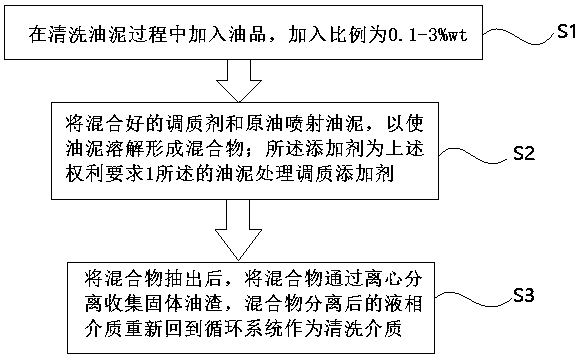

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

[0036] figure 1 Shown is a kind of oil sludge treatment additive, including the following components and proportioning:

[0037] Non-aromatic solvent 60-90%wt;

[0038] Phosphoglycerides 5-15%wt;

[0039] Terpenes 5-15%wt;

[0040] Benzopyridine 5-15%wt; and,

[0041] Stabilizer 0.5-1%wt.

[0042] Preferably, in combination with the above solution, in this embodiment, the non-aromatic solvent includes at least one of biodiesel, saturated fatty acid methyl ester and unsaturated fatty acid methyl ester.

[0043] Preferably, in combination with the above scheme, in this embodiment, the non-aromatic solvent is a mixture of biodiesel, saturated fatty acid methyl ester and unsaturated fatty acid methyl ester.

[0044] Preferably, in combination with the above solution, in this embodiment, the terpene substance is limonene.

[0045] Preferably, in combination with the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com