Preparation process of white cement

A preparation process, white cement technology, applied in the field of white cement preparation process, can solve the problems of reducing clinker output, reducing product appearance, fast solidification, etc., and achieves the effect of reducing quality fluctuation, reducing labor consumption, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

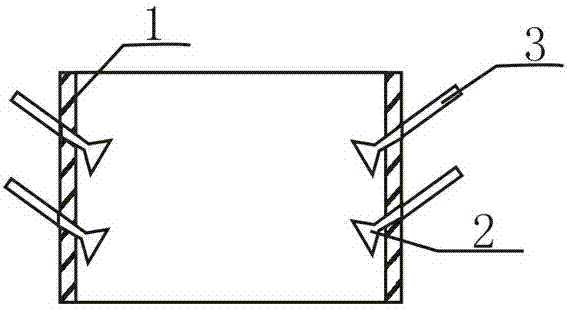

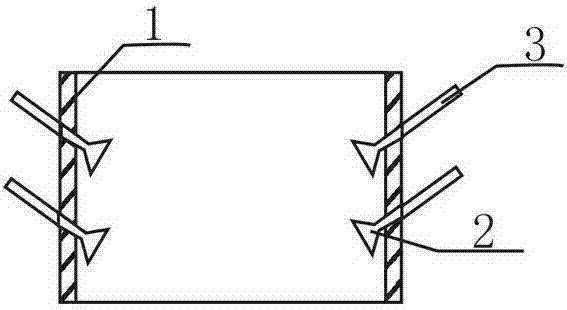

Image

Examples

preparation example Construction

[0023] A kind of preparation technology of white cement, its preparation technology is:

[0024] Step 1. Take 70%-75% of limestone, 20%-25% of siliceous stone and 5% of pyrophyllite by weight percentage, put the limestone, siliceous stone and pyrophyllite into the jaw crusher respectively, and crush them to 2-4cm particles , the calcium content of the limestone is 50%-70%, the silicon content of the chert is 9%-10%, and the chlorine content of the pyrophyllite is 50%-70%;

[0025] Step 2. Put the crushed particles in step 1 into a vertical raw meal mill, grind to 250-300 mesh, take them out and send them to storage tanks, homogenize for 68-78 hours, and take them out;

[0026] Step 3. Put the homogenized raw materials in step 2 into the raw material bin for mixing, take out the mixed raw materials and send them to the storage tank again, homogenize for 72-80 hours, then take them out and send them to the hollow rotary kiln , firing at a temperature of 1500-1800°C for 12-48 ho...

Embodiment 1

[0035] Step 1, get limestone 70%, siliceous stone 25% and pyrophyllite 5% by weight percentage, limestone, siliceous stone and pyrophyllite are put into jaw crusher respectively, be broken into the particle of 2cm, the calcium content of described limestone is 50%, the silicon content of chert is 9%, and the chlorine content of pyrophyllite is 50%;

[0036] Step 2. Put the crushed particles in step 1 into the vertical raw meal mill respectively, and grind them to 250 meshes. After testing, the calcium content in the crushed limestone particles is 50%, and the silicon content in the siliceous stone is 50%. is 9%, and the chlorine content in the pyrophyllite is 50%, which is then sent to the storage tank respectively, homogenized for 68 hours, and taken out;

[0037] Step 3. Put the raw materials homogenized in step 2 into the raw material bin for mixing, take out the mixed raw materials and send them to the storage tank again, and homogenize them for 72 hours. After testing, th...

Embodiment 2

[0042] Step 1, get limestone 73%, siliceous stone 22% and pyrophyllite 5% by weight percentage, limestone, siliceous stone and pyrophyllite are put into jaw crusher respectively, be broken into the particle of 3cm, the calcium content of described limestone 60%, the silicon content of chert is 10%, and the chlorine content of pyrophyllite is 60%;

[0043] Step 2. Put the crushed particles in step 1 into the vertical raw meal mill respectively, and grind them to 280 meshes. After testing, the calcium content in the crushed limestone particles is 60%, and the silicon content in the siliceous stone is 60%. is 10%, and the chlorine content in the pyrophyllite is 60%, which is then sent to the storage tank respectively, homogenized for 72 hours, and taken out;

[0044] Step 3. Put the raw materials homogenized in step 2 into the raw material bin for mixing, take out the mixed raw materials and send them to the storage tank again, and homogenize them for 76 hours. After testing, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com