Grape air-drying device for grape wine processing

An air-drying device and wine technology, applied in the field of wine processing, can solve the problems of coloring, failure of grape fermentation, low quality of wine fermentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

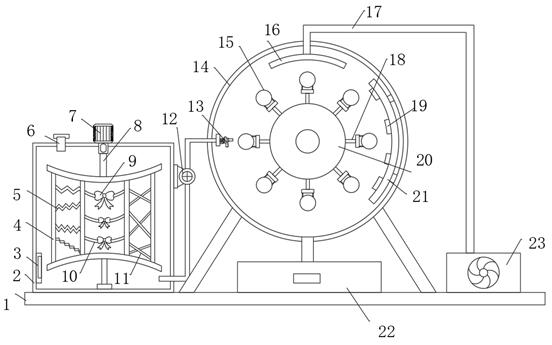

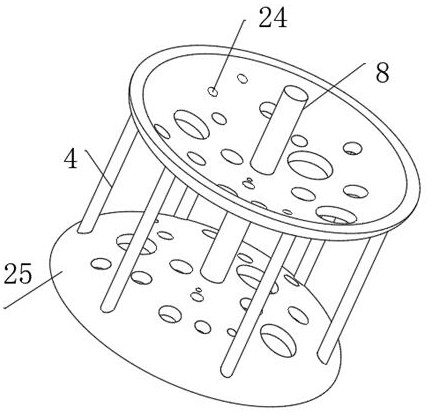

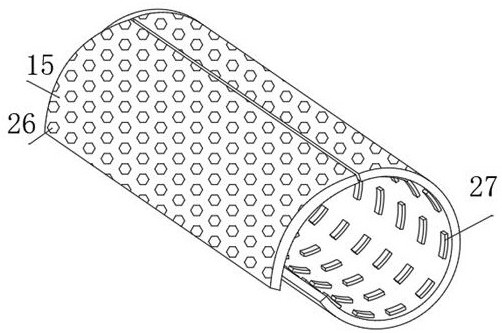

[0030] refer to Figure 1-4 , a grape air-drying device for wine processing, comprising a bottom plate 1, the top outer wall of the bottom plate 1 is fixed with a mixing box 2, an air-drying tank 14 and a hot air blower 23, and the top inner wall of the air-drying tank 14 is fixed with a hot air tray 16 by screws, The inner wall of one side of the hot air tray 16 and the output end of the hot air blower 23 are connected with the same first conduit 17 through a flange, and the inner wall of one side of the air-drying tank 14 is fixed with a liquid spraying plate by screws, and the outer wall of one side of the liquid spraying plate is fixed by screws. Atomizing nozzles 13 distributed equidistantly are fixed, a water pump 12 is fixed on one side of the mixing box 2 by screws, and the input end of the water pump 12 and the side inner wall of the mixing box 2 are connected with the same second conduit through a flange, The output end of the water pump 12 and the inner wall of one ...

Embodiment 2

[0038] refer to Figure 5 , a grape air-drying device for wine processing. Compared with Embodiment 1, this embodiment also includes a temperature sensor 29 fixed to the inner wall of one side of the mixing box 2 by screws, and a display screen 30 is fixed to the outer wall of one side of the mixing box 2 by screws. , and the signal input end of the display screen 30 is connected to the processor through a signal line, and the signal output end of the temperature sensor 29 is connected to the signal input end of the processor through a signal line.

[0039] Connect the device to the power supply, first place the grapes in the grape placement frame 15, turn on the second motor 28, the second motor 28 drives the second rotating rod to rotate, and then the rotating roller 20 and the grape placement frame 15 start to rotate, and turn on the hot air blower 23 Dry the grapes with the drying lamp, turn on the first motor 7, the first motor 7 drives the first rotating rod 8 to rotate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com