Solvent-free waterborne epoxy curing agent and preparation method thereof

A water-based epoxy and curing agent technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of low solid content and high energy consumption in the preparation of water-based epoxy curing agents, achieve high gloss, break through high solid and low viscosity Difficult, low-odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

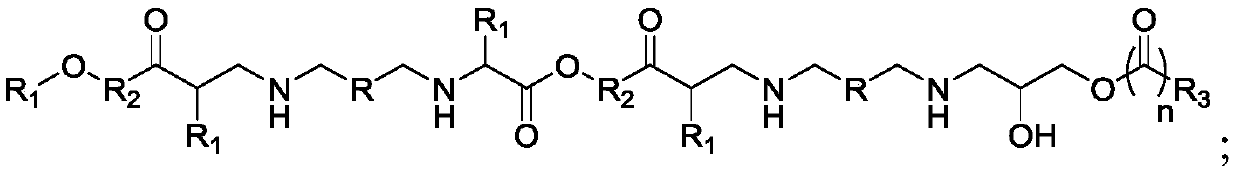

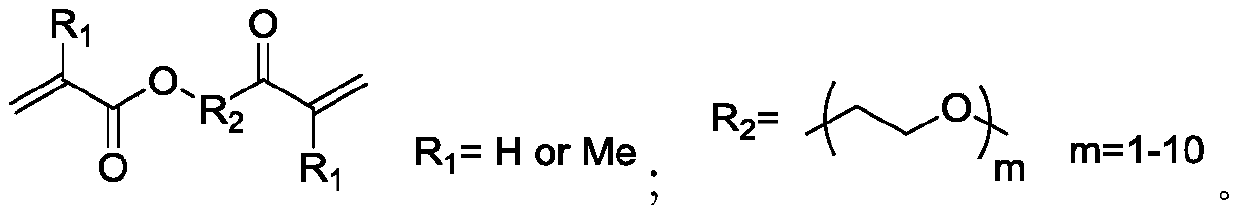

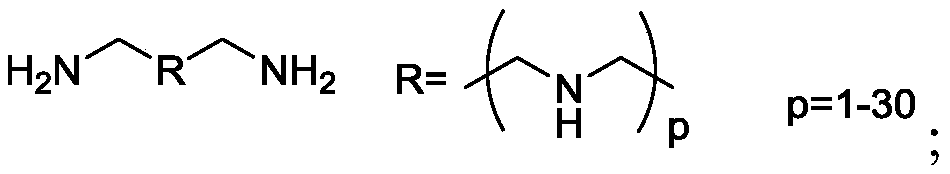

Method used

Image

Examples

Embodiment 1

[0045] 1. Under the protection of nitrogen, add 20.6g of diethylenetriamine into the four-neck flask, start stirring, slowly add 200g of MPEGA (1000) dropwise at room temperature, and continue the reaction at room temperature for 4-8 hours after the dropwise addition.

[0046] 2. Under the protection of nitrogen, add 20.6g of diethylenetriamine into the four-necked flask, start stirring, slowly add 26g of n-butyl glycidyl ether dropwise at room temperature, and continue the reaction at room temperature for 4-8 hours after the drop is completed.

[0047] 3. Pour the above materials into a 500ml flask, start stirring and stir evenly, and slowly add 39.6g of ethylene glycol dimethacrylate dropwise, and continue to react at room temperature for 4-8 hours after the dropping, and the reaction end point is determined by chromatography and amine value .

Embodiment 2

[0049] 1. Under the protection of nitrogen, add 47.3g of triethylenetetramine into the four-neck flask, start stirring, slowly add 90.9g of MPEGA (350) dropwise at room temperature, and continue the reaction at room temperature for 4-8 hours after the dropwise addition.

[0050] 2. Under the protection of nitrogen, add 47.3g of triethylenetetramine into the four-neck flask, start stirring, slowly add 48.6g of tertiary carbonic acid glycidyl ether dropwise at room temperature, and continue the reaction at room temperature for 4-8 hours after dropping.

[0051] 3. Pour the above materials into a 500ml flask, turn on the stirring and stir evenly, and slowly add 68.2g of tripropylene glycol diacrylate dropwise, and continue to react at room temperature for 4-8 hours after the dropping, and the reaction end point is determined by chromatography and amine value.

Embodiment 3

[0053] 1. Under the protection of nitrogen, add 34.1g of triethylenetetramine into the four-necked flask, start stirring, slowly add 164g of MPEGA (1000) dropwise at room temperature, and continue the reaction at room temperature for 4-8 hours after the dropwise addition.

[0054] 2. Under the protection of nitrogen, add 34.1g of triethylenetetramine into the four-necked flask, start stirring, and slowly add 35.8g of tertiary carbonic acid glycidyl ether dropwise at room temperature, and continue the reaction at room temperature for 4-8 hours after the dropping.

[0055] 3. Pour the above materials into a 500ml flask, turn on the stirring and stir evenly, and slowly add 32.5g of ethylene glycol dimethacrylate dropwise, and continue to react at room temperature for 4-8 hours after the dropping, and the reaction end point is determined by chromatography and amine value .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com