Red pigment paste with ultrahigh dispersity

A red pigment, dispersive technology, applied in the direction of pigment slurry, etc., can solve the problems of non-lubricating gel pen writing, ink surface blooming, easy to block the tip of the pen, etc., achieve strong coloring power, low usage, and promote compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

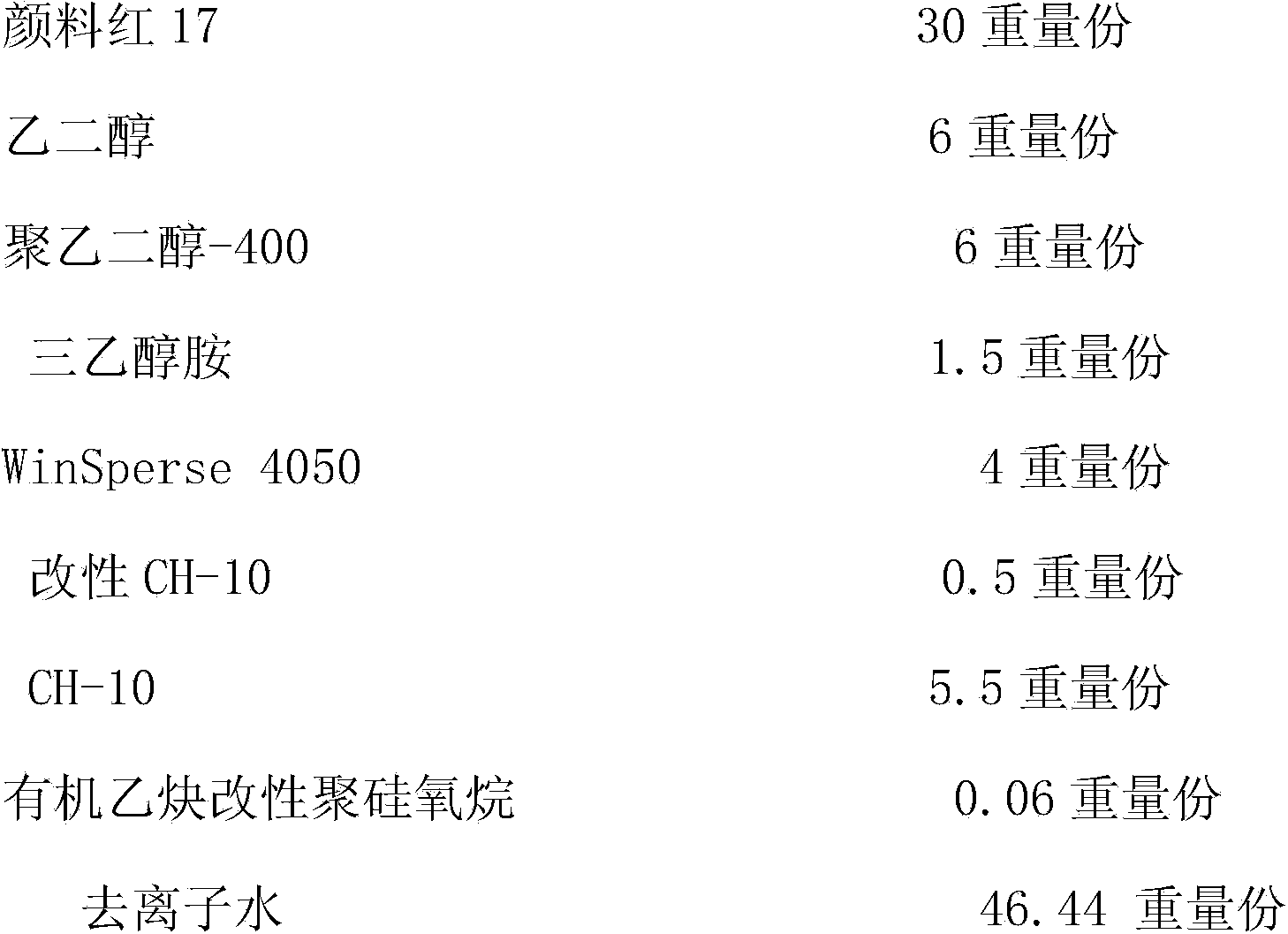

Embodiment 1

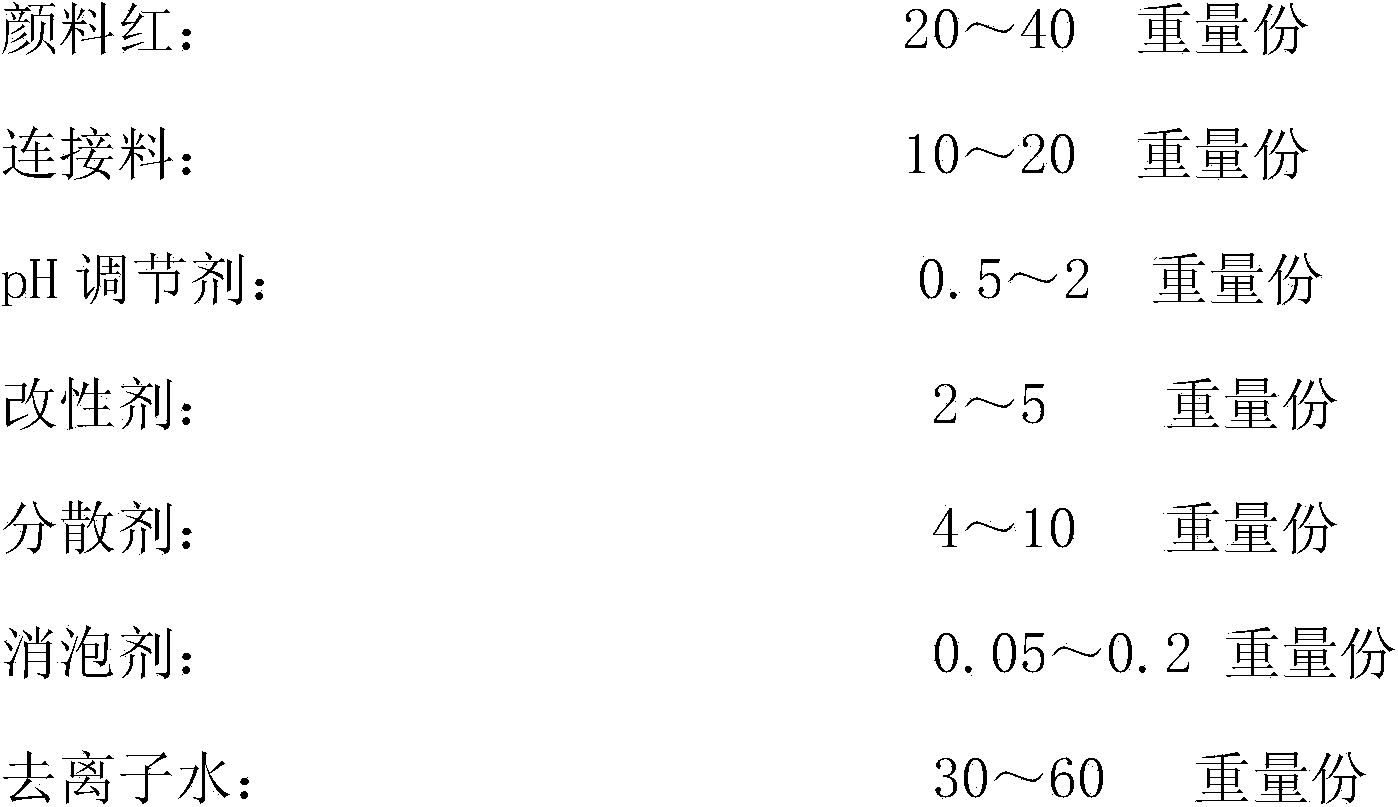

[0022] A kind of ultra-high dispersibility red pigment color paste, its raw material weight composition is:

[0023]

[0024] A preparation method of an ultra-high dispersibility red pigment paste, the concrete steps are:

[0025] 1) Add 46.44 parts by weight of deionized water into the container, then add 0.5 parts by weight of modified CH-10, 5.5 parts by weight of CH-10, and 4 parts by weight of Winsperse4050, and stir until uniform and transparent. Then add 6 parts by weight of ethylene glycol, 6 parts by weight of polyethylene glycol-400, and 1.5 parts by weight of triethanolamine, and stir evenly.

[0026] 2) Add 30 parts by weight of Pigment Red 17, stir while adding the pigment, and then mechanically stir until the pigment is fully wetted.

[0027] 3) Use methods such as colloid mill for pre-dispersion. Then grind in a horizontal sand mill, mechanically stir the circulating material at the same time, add a small amount of defoamer step by step according to the foa...

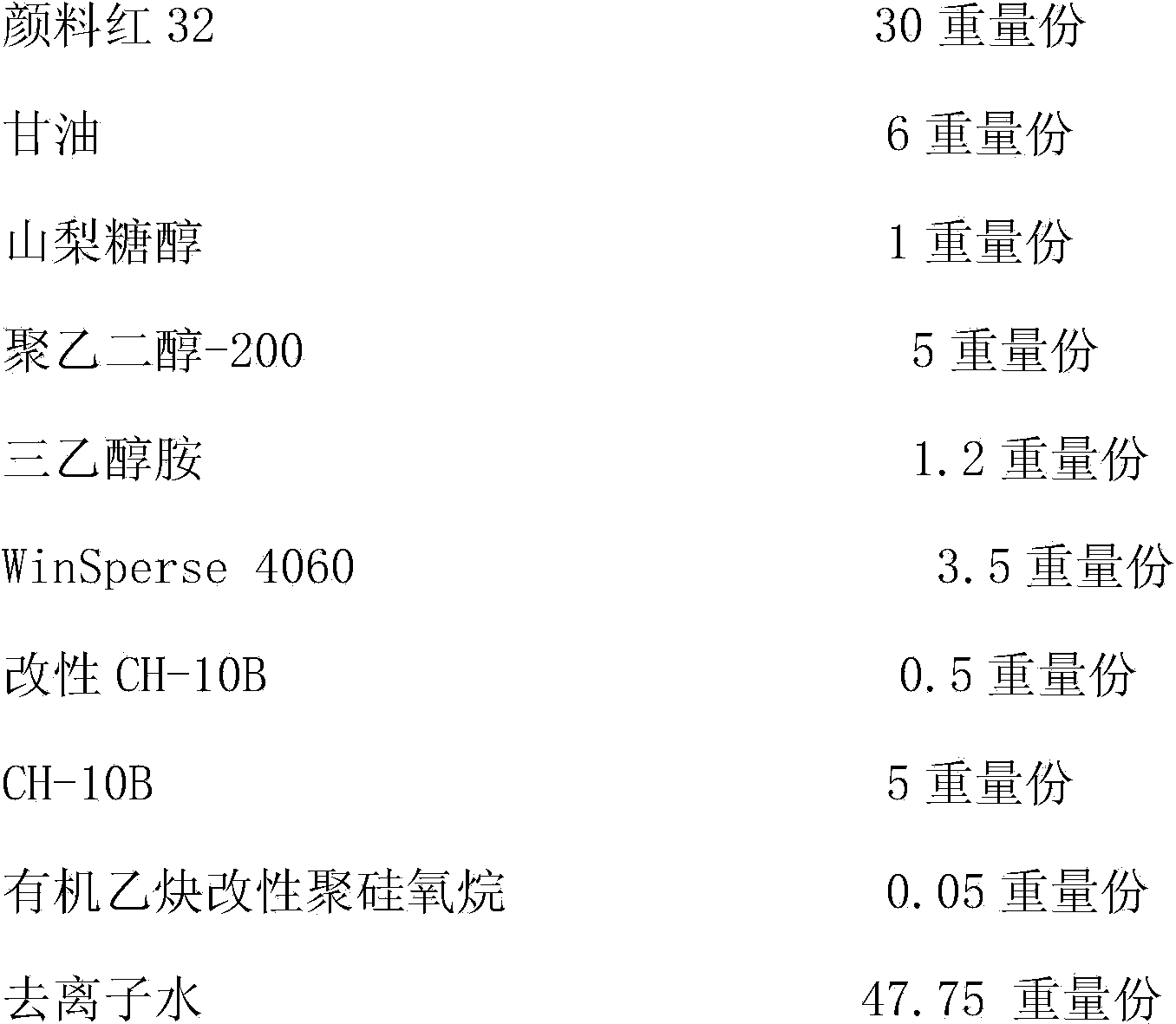

Embodiment 2

[0029] A kind of ultra-high dispersibility red pigment color paste, its raw material weight composition is:

[0030]

[0031] A preparation method of an ultra-high dispersibility red pigment paste, the concrete steps are:

[0032] 1) Add deionized water into the container according to the ratio requirements, then add modified CH-10B, CH-10B, WinSperse4060, stir until uniform and transparent, then add glycerin, sorbitol, polyethylene glycol-200, triethanolamine in sequence , stir well.

[0033] 2) Then add Pigment Red 32, and stir until the pigment is fully wetted while adding the pigment.

[0034] 3) Pre-disperse by high-speed dispersion method. Then grind in a horizontal sand mill while mechanically stirring the circulating material, and add a small amount of defoamer step by step according to the foam condition during the grinding process. Grind for 3 hours at a rotational speed of 2000-3000r / min to obtain the finished color paste.

Embodiment 3

[0036] A kind of ultra-high dispersibility red pigment color paste, its raw material weight composition is:

[0037]

[0038] A preparation method of an ultra-high dispersibility red pigment paste, the concrete steps are:

[0039] 1) Add deionized water into the container according to the above formula requirements, then add modified CH-10S, CH-10S and WinSperse5020, stir until uniform and transparent, then add ethylene glycol, glycerin, maltitol, and triethanolamine in sequence. Mechanically stir evenly.

[0040] 2) Then add Pigment Red 170, and stir until the pigment is fully wetted while adding the pigment.

[0041] 3) Ultrasonic method is used for pre-dispersion. Then grind in a horizontal sand mill while mechanically stirring the circulating material, and add a small amount of defoamer step by step according to the foam condition during the grinding process. Grind for 3.5 hours at a rotational speed of 2000-3000r / min to obtain the finished color paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com