Blue silk sericin lyophilized ball and preparation method thereof

A technology of sericin and freeze-drying, which is applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of easy breakage, easy shrinkage, poor forming effect of freeze-dried balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

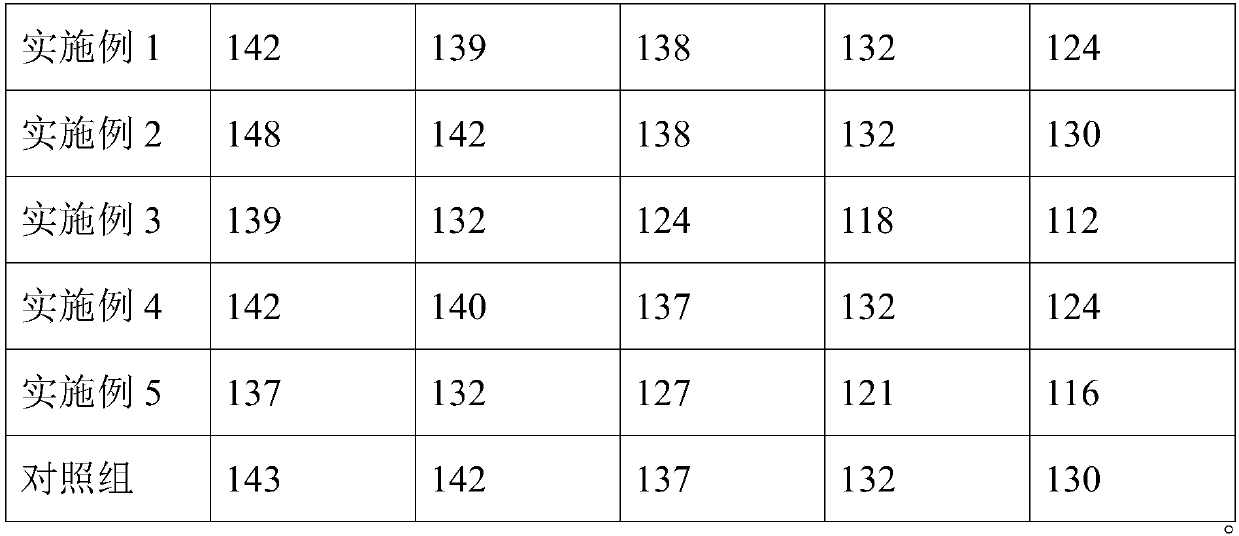

Embodiment 1

[0017] A kind of blue sericin freeze-dried ball, the formula is as follows according to mass percentage: 10% of sericin, 2% of sodium hyaluronate (1 million daltons), 25% of mannitol, 10% of pullulan , tripeptide-1 copper 0.3%, sterile deionized water added to 100%.

[0018] The preparation method of the present invention comprises the following steps:

[0019] (1) Weigh sodium hyaluronate, mannitol, pullulan plus sterile deionized water, heat to 70-80°C, and prepare a uniform and transparent solution;

[0020] (2) When the temperature of the solution in step 1 is lowered to 25-35°C, add sericin and tripeptide-1 copper, and stir evenly;

[0021] (3) Aseptically freeze the dosing solution obtained in step 2 in a GMP production environment, and mold it into a ball (1 cm in diameter);

[0022] (4) Transfer the ice balls obtained in step 3 to a pre-sterilized and pre-frozen freeze dryer at -40--50°C, and directly freeze-dry for 20-40 hours;

[0023] (5) Freeze-drying is complet...

Embodiment 2

[0025] A kind of blue sericin freeze-dried ball, formula is as follows according to mass percentage: 25% of sericin, 2% of sodium hyaluronate (1.1 million Daltons), 25% of mannitol, 10% of pullulan , tripeptide-1 copper 0.3%, sterile deionized water added to 100%.

[0026] The preparation method of the present invention comprises the following steps:

[0027] (1) Weigh sodium hyaluronate, mannitol, pullulan plus sterile deionized water, heat to 70-80°C, and prepare a uniform and transparent solution;

[0028] (2) When the temperature of the solution in step 1 is lowered to 25-35°C, add sericin and tripeptide-1 copper, and stir evenly;

[0029] (3) Aseptically freeze the dosing solution obtained in step 2 in a GMP production environment, and mold it into a ball (1 cm in diameter);

[0030] (4) Transfer the ice balls obtained in step 3 to a pre-sterilized and pre-frozen freeze dryer at -40--50°C, and directly freeze-dry for 20-40 hours;

[0031] (5) Freeze-drying is completed...

Embodiment 3

[0033] A kind of blue sericin freeze-dried ball, formula is as follows according to mass percentage: 25% of silk sericin, 2% of sodium hyaluronate (1.2 million daltons), 25% of mannitol, 10% of pullulan , tripeptide-1 copper 0.6%, sterile deionized water added to 100%.

[0034] The preparation method of the present invention comprises the following steps:

[0035] (1) Weigh sodium hyaluronate, mannitol, pullulan plus sterile deionized water, heat to 70-80°C, and prepare a uniform and transparent solution;

[0036] (2) When the temperature of the solution in step 1 is lowered to 25-35°C, add sericin and tripeptide-1 copper, and stir evenly;

[0037] (3) Aseptically freeze the dosing solution obtained in step 2 in a GMP production environment, and mold it into a ball (1 cm in diameter);

[0038] (4) Transfer the ice balls obtained in step 3 to a pre-sterilized and pre-frozen freeze dryer at -40--50°C, and directly freeze-dry for 20-40 hours;

[0039] (5) Freeze-drying is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com