Preparation method of high energy-saving and environment-friendly type phthalocyanine green pigment

An energy-saving and environmentally friendly, phthalocyanine green technology, which is applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as need for recycling, high electric energy, and high risk, so as to reduce the viscosity of the system, reduce the reaction temperature, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

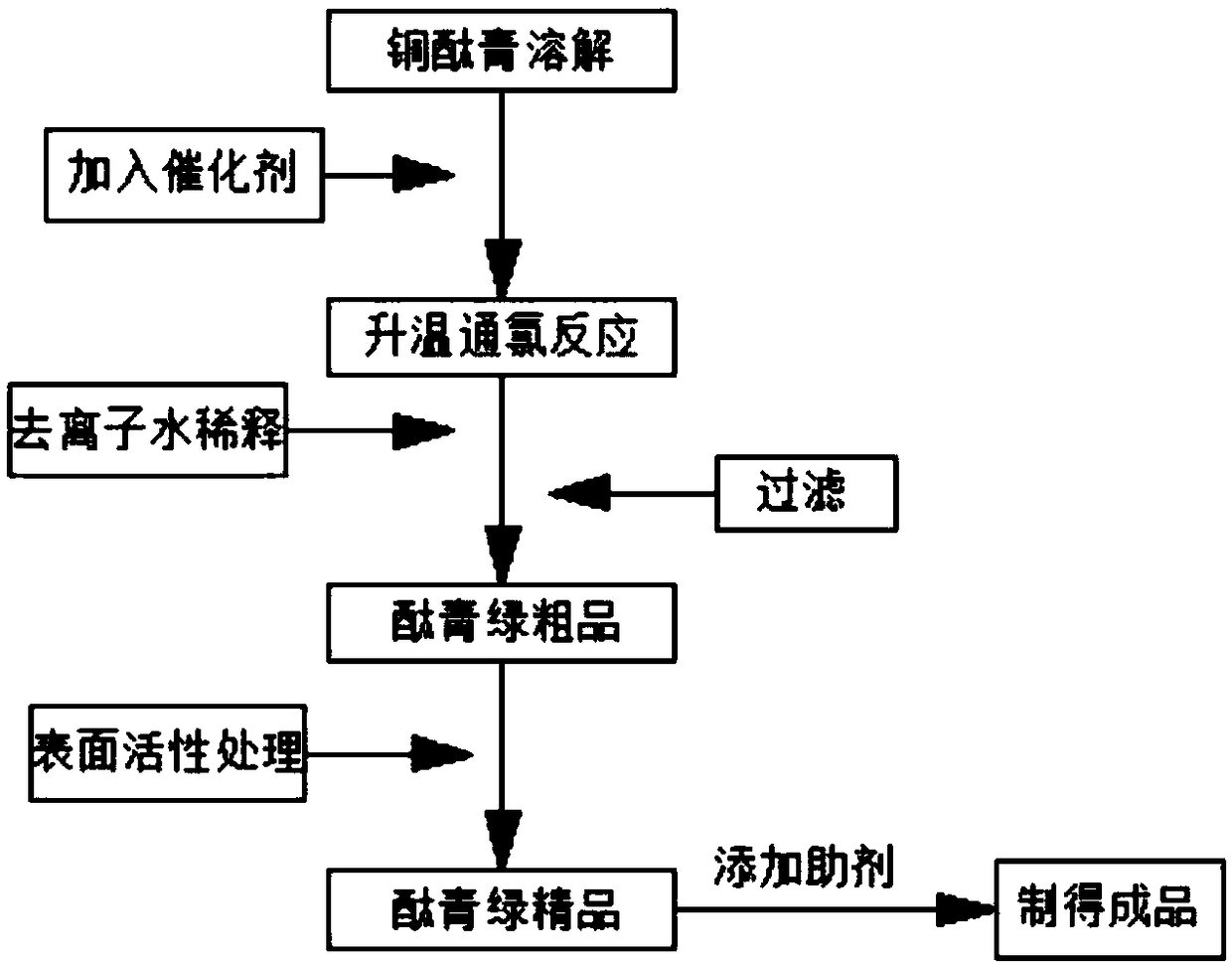

[0020] A preparation method of high energy-saving and environment-friendly phthalocyanine green pigment, the specific steps of the method are as follows:

[0021] S1: After dissolving the copper phthalocyanine in advance, add 6g of ferric chloride, raise the temperature to 100°C to carry out the chlorine flow reaction, the chlorine flow reaction is carried out under the pressure of 0.3MPa, and the reaction time is 1h;

[0022] S2: The reactant was diluted with 200ml of deionized water, and the crude phthalocyanine green was obtained after filtration;

[0023] S3: Put the crude phthalocyanine green into n-octanol, stir at a certain temperature for 1 hour at 60°C to fully disperse it in n-octanol, then add 5 g of sodium linear alkylbenzene sulfonate to fully Stir, and remove n-octanol by steam distillation, obtain phthalocyanine green fine product after filtering and drying;

[0024] S4: Mix the fine phthalocyanine green product into 400ml of polyester resin, add 20ml of thicke...

Embodiment 2

[0026] A preparation method of high energy-saving and environment-friendly phthalocyanine green pigment, the specific steps of the method are as follows:

[0027] S1: After dissolving the copper phthalocyanine in advance, add 8g of antimony trichloride, heat up to 120°C to carry out the chlorine reaction, the chlorine reaction is carried out under the pressure of 0.5MPa, and the reaction time is 3h;

[0028] S2: The reactant was diluted with 300ml of deionized water, and the crude phthalocyanine green was obtained after filtration;

[0029] S3: Put the crude phthalocyanine green into n-octanol, stir for 3 hours at a certain temperature, the stirring temperature is 80°C, so that it is fully dispersed in n-octanol, and then add 7g of fatty alcohol polyoxyethylene ether sodium sulfate to fully Stir, and remove n-octanol by steam distillation, obtain the phthalocyanine green fine product after filtering and drying;

[0030] S4: Mix the fine phthalocyanine green product into 600ml...

Embodiment 3

[0032] A method for preparing a high-energy-saving and environment-friendly phthalocyanine green pigment, the specific steps of the method are as follows:

[0033] S1: After dissolving the copper phthalocyanine in advance, add 7g of sulfur, heat up to 110°C to carry out the chlorine reaction, the chlorine reaction is carried out under the pressure of 0.4MPa, and the reaction time is 2h;

[0034] S2: The reactant was diluted with 280ml of deionized water, and the crude phthalocyanine green was obtained after filtration;

[0035] S3: Put the crude phthalocyanine green into n-octanol, stir for 2 hours at a certain temperature, the stirring temperature is 70°C, so that it is fully dispersed in n-octanol, then add 6g of sodium lauryl sulfate to fully stir, and steam n-octanol was removed by distillation, and the fine product of phthalocyanine green was obtained after filtration and drying;

[0036] S4: Mix the fine phthalocyanine green product into 500ml of silicone resin, add 25m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com