Durable UV curable coatings

A coating, weight technology, applied in the direction of coating, polyester coating, epoxy coating, etc., can solve the problem of less than ideal floor appearance and easy wear of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

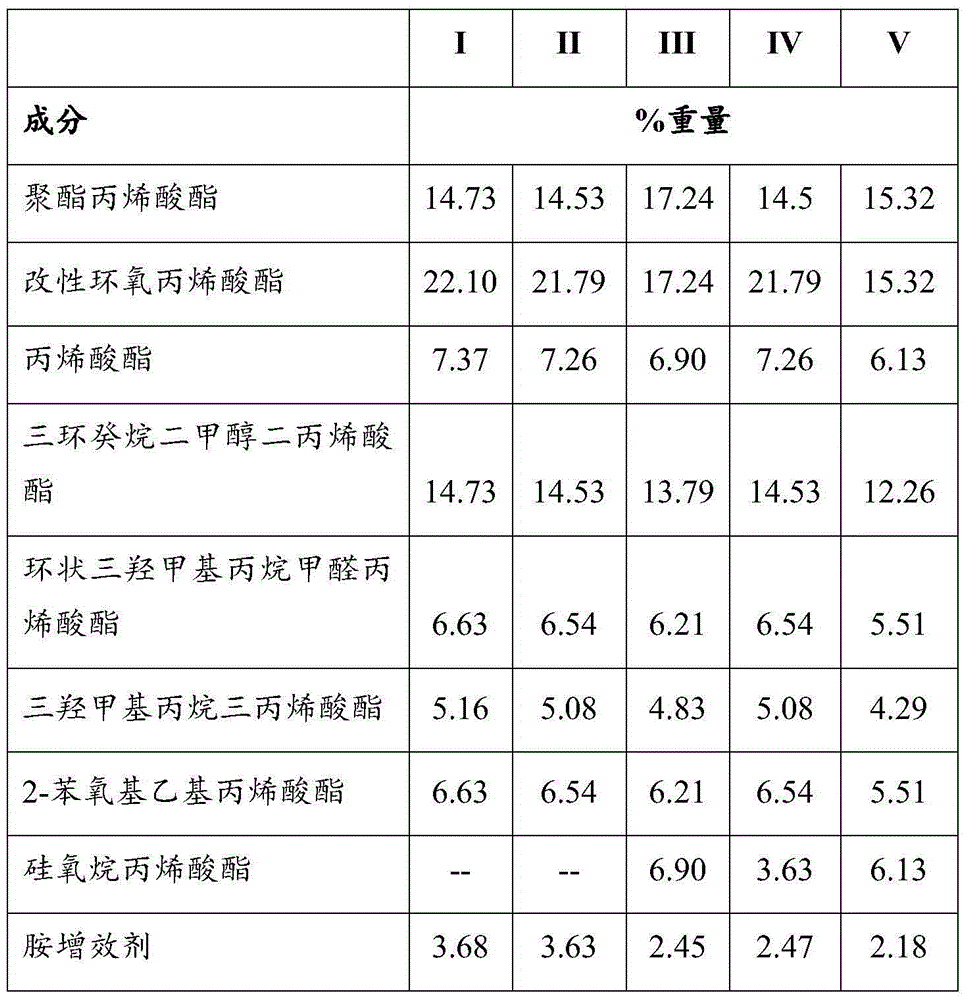

[0075] Five (5) exemplary coatings of the present invention are described in Table 1 (below). These coatings are made by conventional methods readily understood by those skilled in the art.

[0076] Table 1

[0077]

[0078]

Embodiment 2

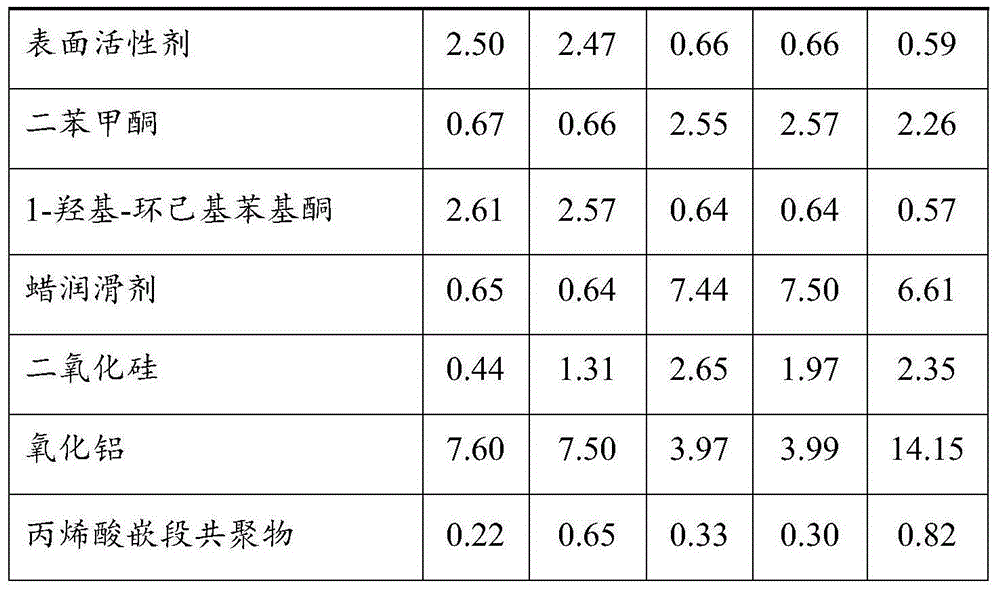

[0080] The ability of the coatings of the present invention to resist heel abrasion was evaluated against an acrylate coating that did not contain the combination of ingredients provided by the embodiments of the present invention. Specifically, the coatings were applied to substrates and evaluated for ease of abrasion and ease of mar removal. The data described in Table 2 (below) demonstrates that the inventive coatings (I-V) provided acceptable levels of heel abrasion resistance, whereas the comparative acrylate coating (CI-CV) not containing the inventive combination of ingredients did not. . "P" indicates an acceptable level of heel scuff resistance, while "F" indicates an unacceptable level of heel scuff resistance. Additionally, it is worth noting that the comparative acrylate coatings are much more prone to abrasion than the inventive coatings.

[0081] Table 2

[0082]

Embodiment 3

[0084] The ability of the coatings of the invention to resist abrasion was evaluated against an acrylate coating that did not contain the combination of ingredients provided by the embodiments of the invention. Specifically, the coatings were applied to substrates and each coated substrate was exposed to 320 grit sandpaper in a Byk Gardner Abrasion Tester for thirty (30) cycles . Gloss measurements were taken before and after completion of 30 cycles. Gloss readings before and after exposure were compared and percent gloss retention was calculated.

[0085] The data described in Table 3 (below) demonstrates that inventive coatings (I-V) provide acceptable levels of abrasion / scratch resistance compared to comparative acrylate coatings (CI- CV) not provided.

[0086] table 3

[0087] coating

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com