Silicon carbide single crystal substrate

一种碳化硅单晶、基板的技术,应用在单晶生长、单晶生长、晶体生长等方向,能够解决薄膜结晶缺陷、异常生长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

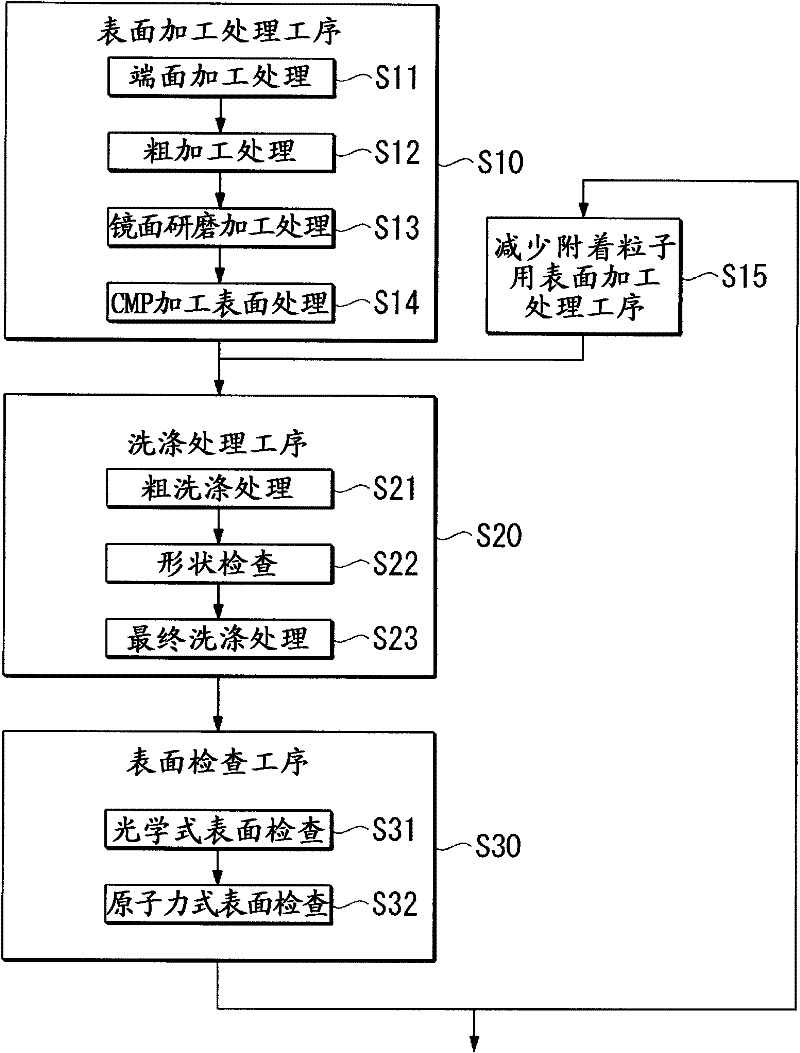

[0086] use figure 1 A silicon carbide single crystal substrate (sample of Example 1) was produced in the process of producing a silicon carbide single crystal substrate shown in the flowchart.

[0087]

[0088] First, a (0001) 8° inclined substrate of a silicon carbide single crystal substrate having a diameter of about 50 mmΦ is prepared, and a predetermined end surface processing is performed.

[0089] Next, the silicon carbide single crystal substrate is sandwiched between the upper and lower two flat stages, and the two stages are rotated facing each other while supplying abrasives, and the front and back surfaces of the above-mentioned silicon carbide single crystal substrate are shaved to adjust the thickness. Rough machining was performed to improve the flatness. As the processing abrasive grains, diamond abrasive grains were used.

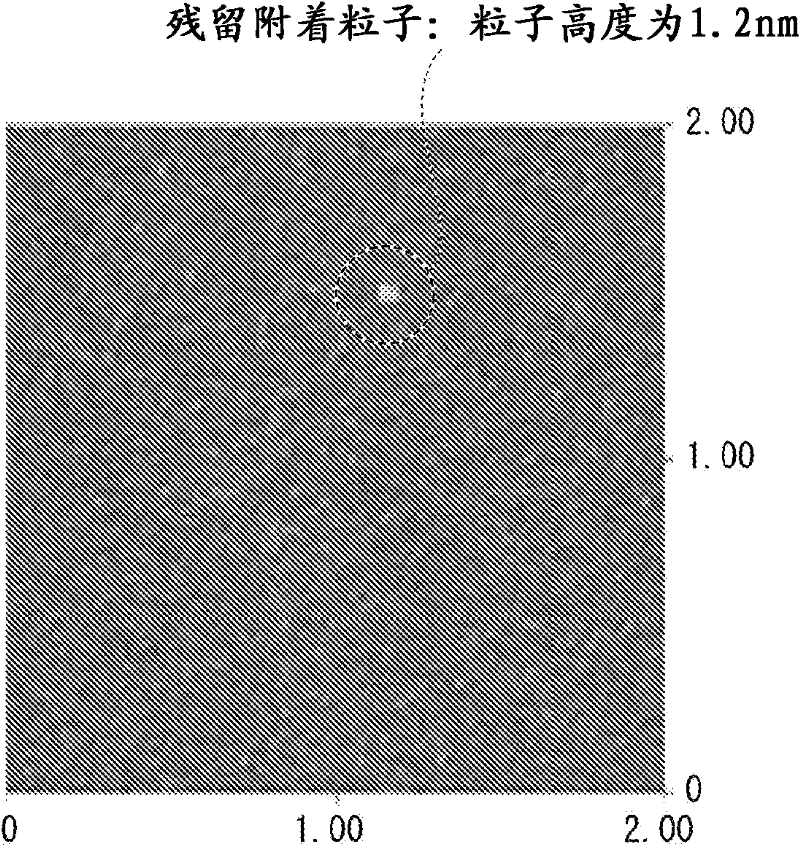

[0090] Next, attach a nonwoven fabric or the like to the processed surfaces of the upper and lower flat platforms, sandwich the silic...

Embodiment 2

[0106] After the surface processing step was completed, the board was mounted on a single-sided processing machine, and the time for surface cleaning performed by supplying only pure water was set to 1 minute, and a silicon carbide single crystal substrate was performed in the same manner as in Example 1 ( Embodiment 2 sample) making.

[0107] After adjusting the pH value of the surface of the silicon carbide single crystal substrate to 1 using an abrasive containing diamond abrasive grains and an abrasive cloth impregnated with a pH adjuster, and performing a surface treatment process (mirror polishing treatment) for reducing attached particles , and repeatedly carry out the above-mentioned washing treatment process. Thereafter, the surface inspection process is performed again.

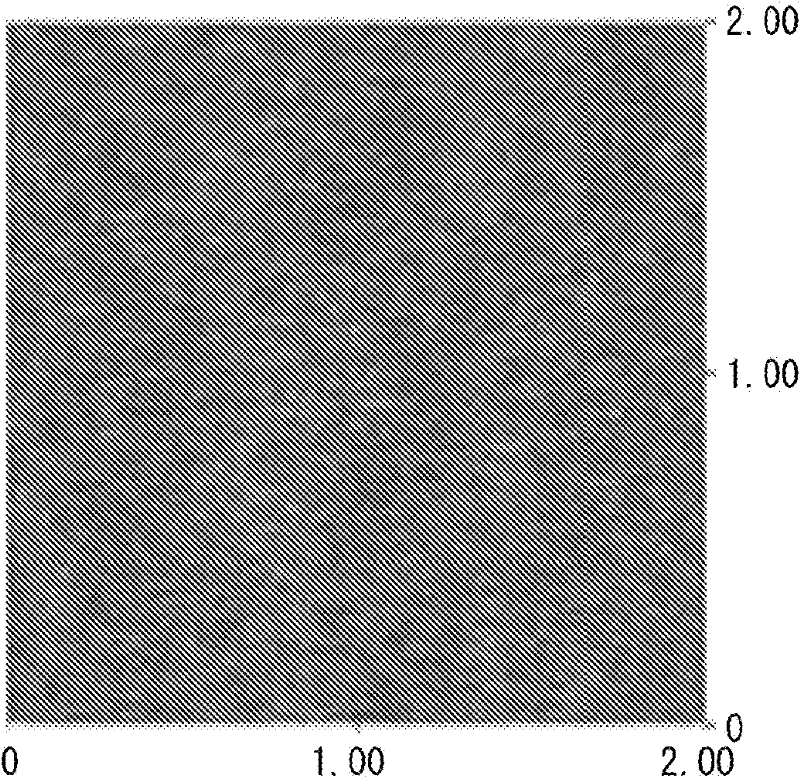

[0108] In the dark-field visual inspection of silicon carbide single crystal substrates and optical surface inspections using SurfScan (manufactured by Tencor Corporation), no surface flaws, cloudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com