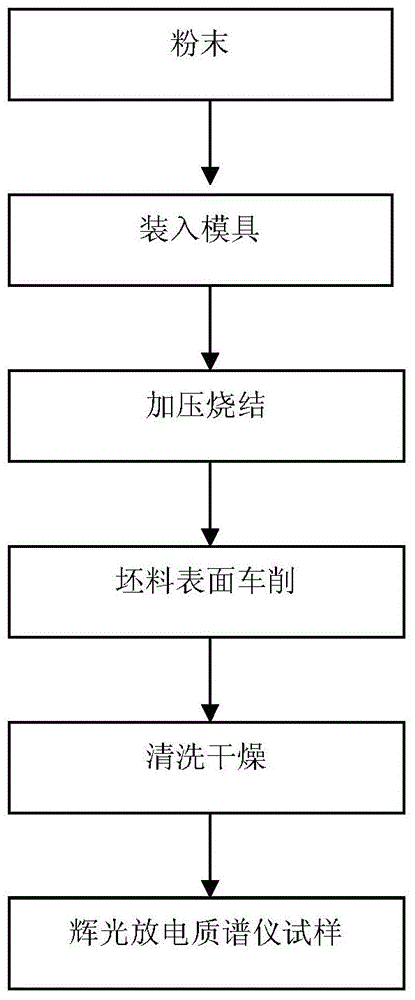

Method for preparing glow discharge mass spectrometer analysis test sample

A technique for glow discharge mass spectrometry and sample analysis, which is used in the preparation of samples for testing, material analysis by electromagnetic means, and material analysis. Accuracy and other issues, to achieve the effect of clean surface, fast analysis speed and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

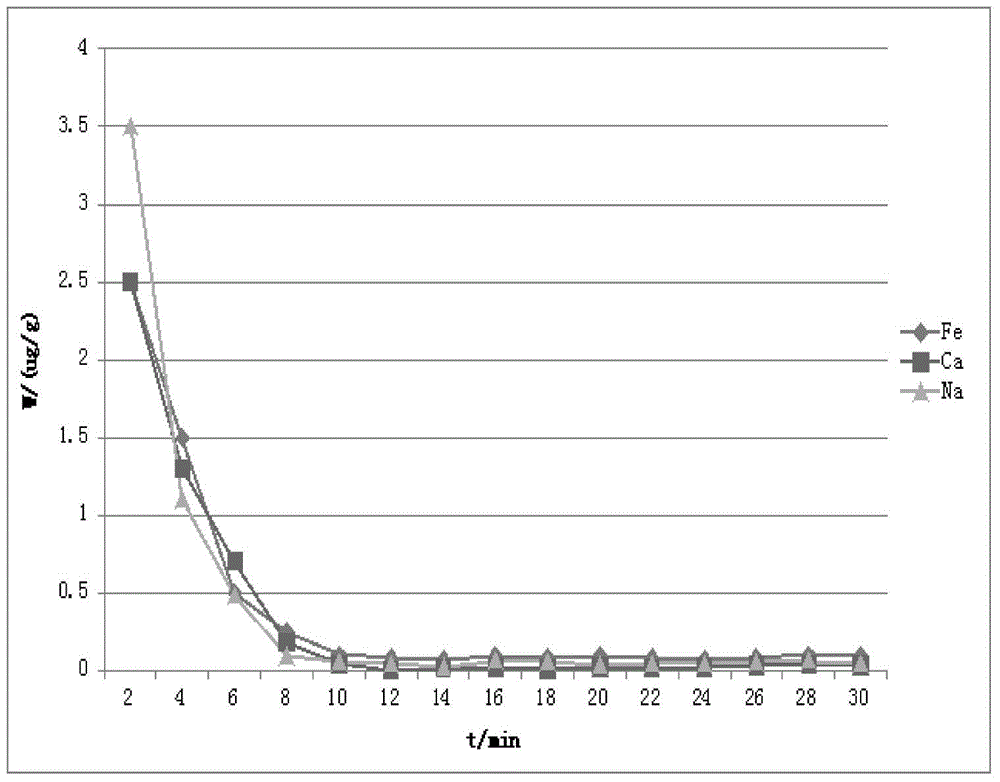

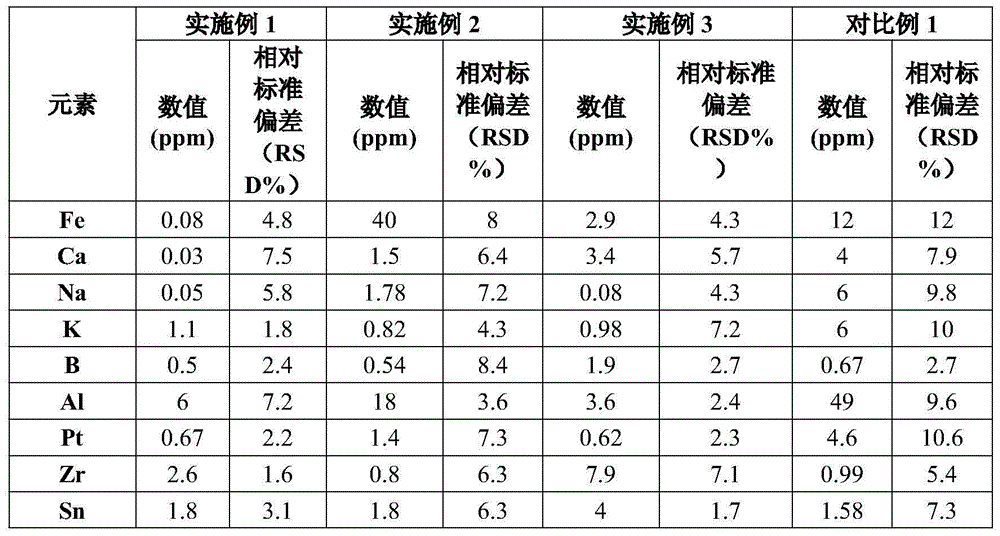

Embodiment 1

[0029] Example 1 Put the ruthenium powder to be analyzed into a graphite mold coated with alumina. The inner diameter of the graphite mold is 30 mm. The ruthenium powder is pressurized and sintered at a temperature of 1300° C. by vacuum hot pressing, and the applied The pressure is 40MPa. After the sintering is completed, the density of the obtained ruthenium block is measured by the Archimedes method, which can reach 99% of the theoretical density of ruthenium. A polycrystalline cubic boron nitride turning tool was used to turn the ruthenium block into a ruthenium sample with a diameter of 28 mm. The ruthenium samples were ultrasonically cleaned with acetone, ethanol and ultrapure water, and dried. Put the sample into the ElementGD block sample stage, and carry out pre-sputtering for a certain period of time, with easily polluted Na, Fe, Ca as the target, start to collect data when the concentration is basically stable, record the time of pre-sputtering, and collect part of ...

Embodiment 2

[0031] Put the ruthenium powder to be analyzed into a graphite mold coated with zirconia. The inner diameter of the graphite mold is 30mm. The ruthenium powder is pressure-sintered at a temperature of 1000°C by spark plasma sintering. The applied pressure is 20MPa. After the sintering is completed, the density of the obtained ruthenium block is measured by the Archimedes method, which can reach 95% of the theoretical density of ruthenium. The ruthenium block was turned into a ruthenium sample with a diameter of 28 mm using a cemented carbide turning tool. The ruthenium samples were ultrasonically cleaned with acetone, ethanol and ultrapure water, and dried. Put the sample into the Element GD block sample stage and perform pre-sputtering for a certain period of time. Taking easily polluted Na, Fe, Ca as the target, start collecting data when its concentration is basically stable, record the time of pre-sputtering, and collect five sets of data of some typical elements at the ...

Embodiment 3

[0033] Put the ruthenium powder to be analyzed into a graphite mold coated with boron nitride. The inner diameter of the graphite mold is 30 mm. The ruthenium powder is pressure sintered at a temperature of 1200 by direct current heating and sintering, and the applied pressure is 30 MPa. . After the sintering is completed, the density of the obtained ruthenium block is measured by the Archimedes method, which can reach 97% of the theoretical density of ruthenium. A diamond turning tool was used to turn the ruthenium block into a ruthenium sample with a diameter of 28 mm. The ruthenium samples were ultrasonically cleaned with acetone, ethanol and ultrapure water, and dried. Put the sample into the Element GD block sample stage and perform pre-sputtering for a certain period of time. Taking easily polluted Na, Fe, Ca as the target, start collecting data when its concentration is basically stable, record the time of pre-sputtering, and collect five sets of data of some typical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com