Physical pretreatment and electrophoresis coating process of aluminum magnesium alloy

An electrophoretic coating, aluminum-magnesium alloy technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of human and environmental hazards, high process implementation costs, and human health pollution, etc. Environmental pollution and harm to human body, the effect of dense and beautiful coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

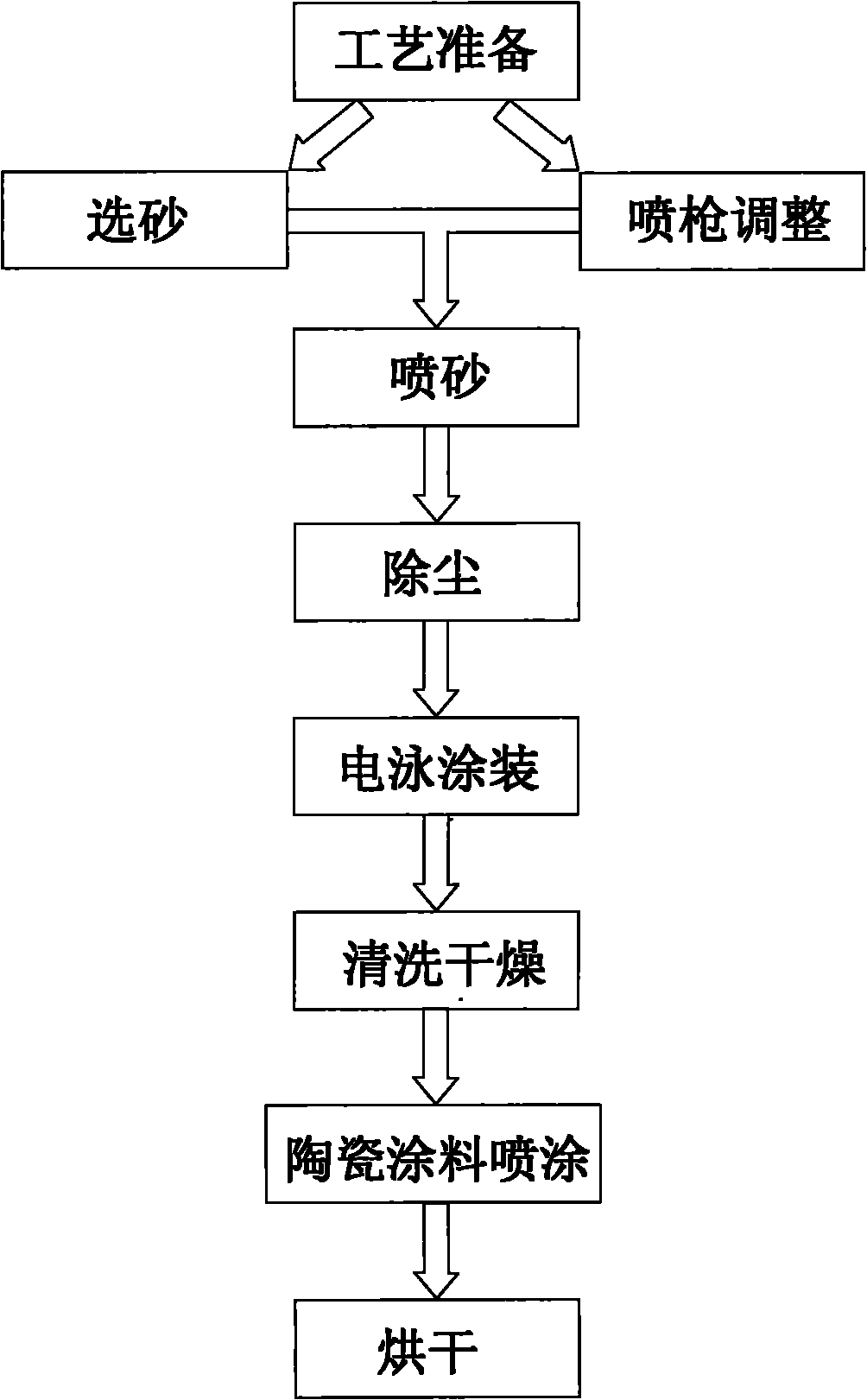

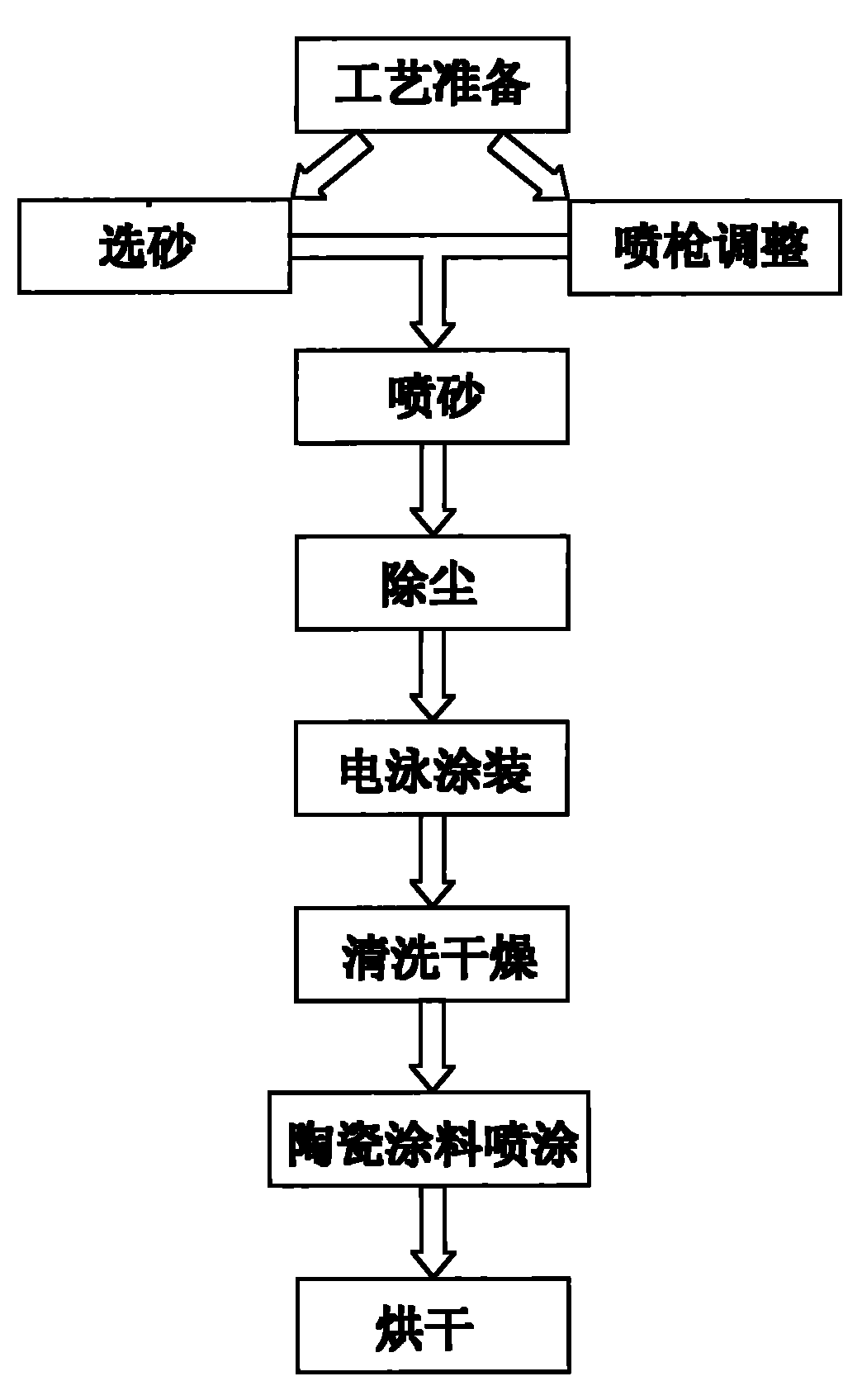

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] A physical pretreatment and electrophoretic coating process for aluminum-magnesium alloys. The process is divided into physical pretreatment and electrophoretic coating. The physical pretreatment is surface sandblasting. The roughness is used to determine the size and type of sand grains used, specifically: the roughness is 2.0-2.5um, and the sand type is 16 # ;The roughness is 1.0~1.5um, the sand mold is 46 # ;The roughness is 0.8~1.0um, the sand mold is 80 # ;The roughness is 0.7~0.8um, the sand mold is 90 # ;The roughness is 0.5~0.6um, the sand mold is 120 # .

[0023] Aluminum-magnesium alloy physical pretreatment and electrophoretic coating process of the present invention, such as figure 1 As shown, the technological process is carried out in the following steps:

[0024] Step 1. Select the sand grains according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com