Slow-releasing bFGF-PLA-PEG microball and its prepn and use

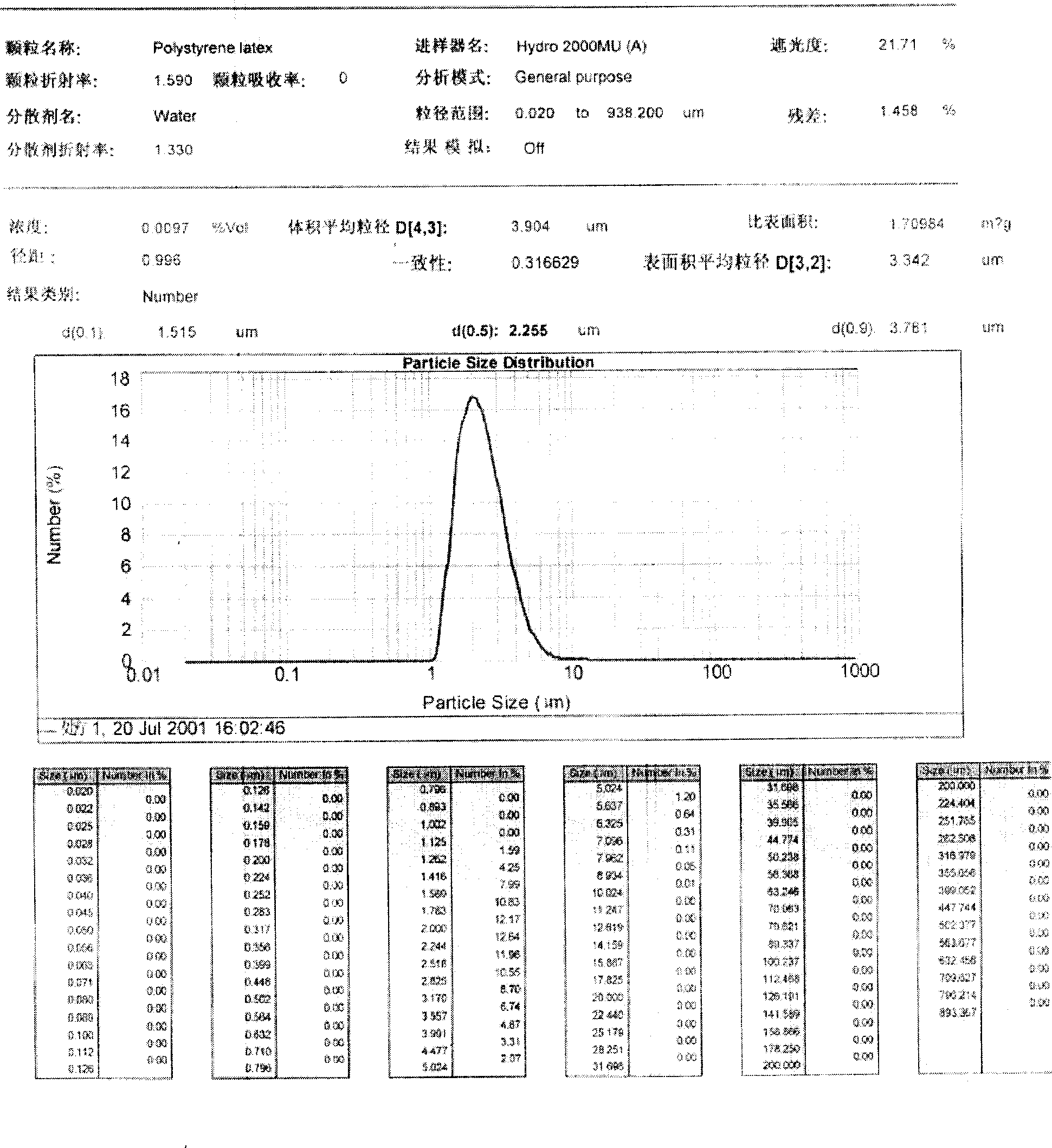

A microsphere and slow-release technology, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, peptide/protein components, etc., can solve the problems of no bFGF microspheres, and achieve improved drug release in vitro and particle size Distribution, the effect of improving the encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Accurately weigh 150 mg of PLA-PEG and other auxiliary materials and dissolve them in an organic solvent to form an oil phase. The organic solvent is dichloromethane (DCM) or a mixture of dichloromethane (DCM) and acetone (AC), and the volume percentage of DCM and AC is 75-100:0-35. 100 μg bFGF sample was dissolved in double distilled water to form the aqueous phase. The bFGF solution is added to the above oil phase, which forms colostrum after homogenization. Weigh an appropriate amount of PVA or / and PEG into double-distilled water, bathe in a 50°C water bath to fully dissolve, and adjust the concentration to 5%. Inorganic salts are added to the aqueous dispersion medium solution, so that the concentration of the outer aqueous phase is 2% or higher. Add the above emulsion dropwise to 2ml of PVA or PVA-PEG solution, homogenize again, then pour this solution into 8ml of PVA or PVA-PEG solution of the same concentration, and stir magnetically at room temperature for 3-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com