Lamelliferous color master batch and manufacturing method thereof

A flaky, color masterbatch technology, applied in the field of plastic coloring, can solve the problems of large color difference changes, high reject rate, unstable color of plastic products, etc., to achieve the effect of ensuring stability and maintaining stable concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

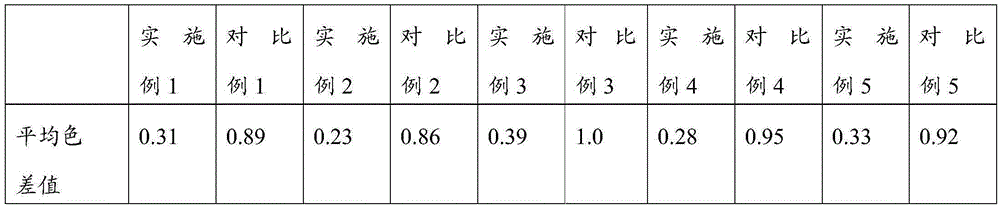

Examples

Embodiment 1

[0027] Take 10kg of polyethylene, 60kg of titanium dioxide, 1kg of aluminate coupling agent, 10kg of low molecular weight polyethylene wax, and 19kg of calcite powder. The special flat hole die of the machine head is formed into a flat strip, which is cooled by a water tank, and then pelletized by a pelletizer, supplemented by adjusting the traction speed of the pelletizer to adjust the side length and thickness of the color masterbatch to make a side length 2mm×3mm, 0.5mm thick flake color masterbatch.

Embodiment 2

[0031] Take 90kg of polypropylene, 0.5kg of phthalocyanine blue, 0.1kg of titanate coupling agent, 5kg of ethylene bisstearamide, and 4.4kg of talcum powder. It is formed into a flat strip by the special flat hole die of the extruder head, cooled by a water tank, and then pelletized by a pelletizer, supplemented by adjusting the traction speed of the pelletizer to adjust the side length and thickness of the color masterbatch , to make a flake color masterbatch with a side length of 10mm×5mm and a thickness of 1mm.

Embodiment 3

[0035] Take 40kg of polystyrene, 20kg of modified polystyrene, 25kg of mica titanium pearl powder, 1kg of transparent red EG, 14kg of low molecular weight ethylene-vinyl acetate copolymer wax, 0kg of coupling agent, and 0kg of filler. The twin-screw extruder is melted, kneaded and extruded. It is formed into a flat strip through the special flat hole die of the extruder head. It is cooled by a water tank, and then pelletized by a pelletizer, supplemented by adjusting the traction of the pelletizer. Adjust the side length and thickness of the color masterbatch according to the speed, and make a flake color masterbatch with a side length of 8mm×6mm and a thickness of 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com