Gas management apparatus and method for excimer laser

A technology of excimer lasers and management devices, which is applied in the field of excimer lasers, can solve the problems of large concentration and working voltage variation range, difficulty in precisely controlling laser concentration, complex structure of gas management devices, etc., and achieves simple structure, reduced cost, and reduced The effect of the accumulation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

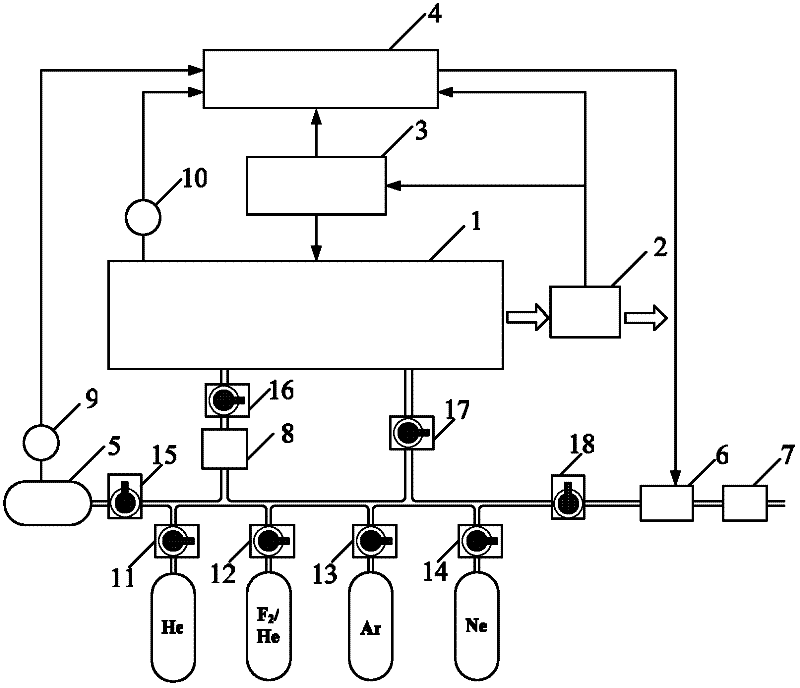

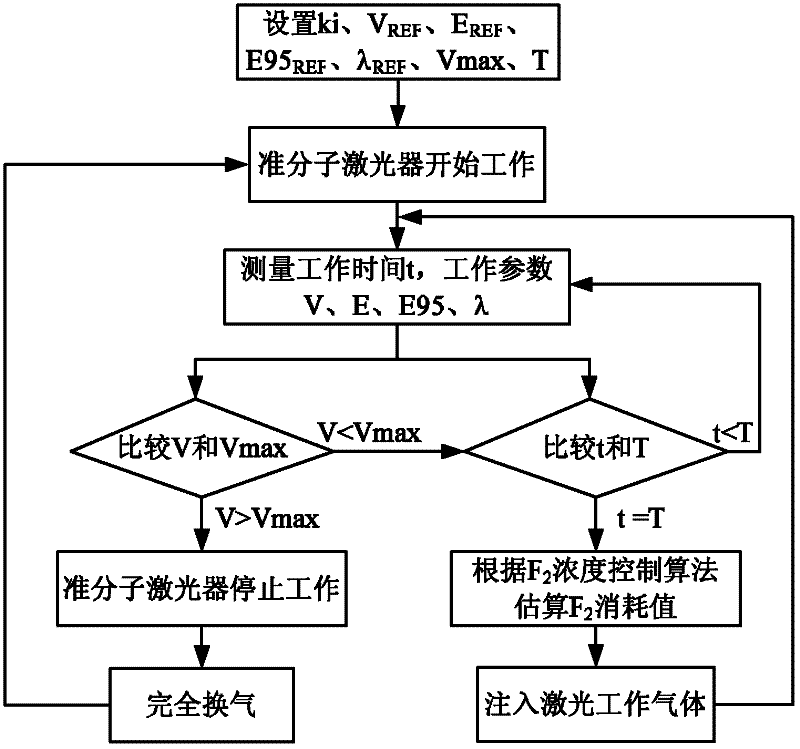

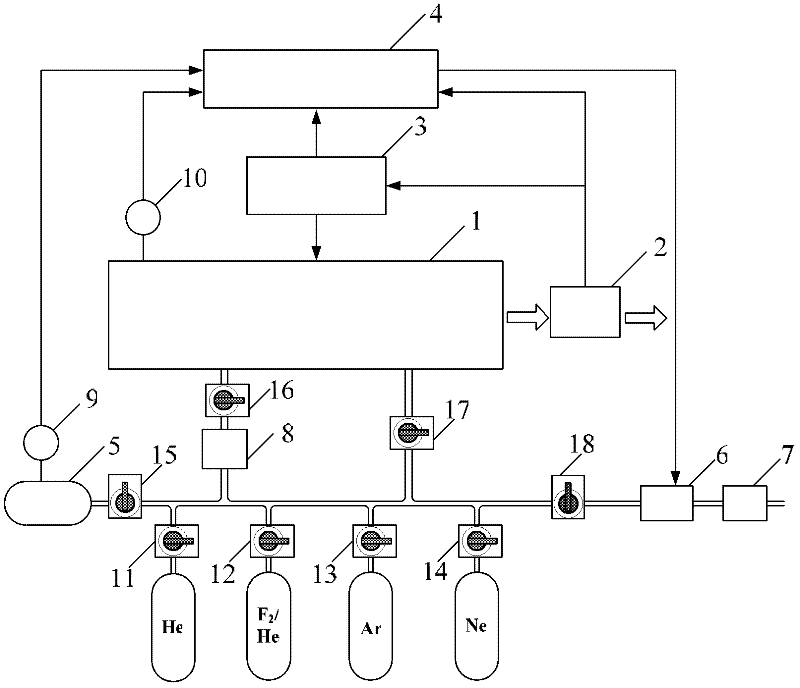

[0026] like figure 1 As shown, the excimer laser gas management device provided by the present invention includes an excimer laser 1, a monitoring module 2, a voltage control module 3, a gas management control module 4, a gas injection tank 5, a vacuum pump 6, a halogen gas processing device 7, a limiter Flow device 8, first pressure sensor 9, second pressure sensor 10, first controllable electromagnetic valve 11, second controllable electromagnetic valve 12, third controllable electromagnetic valve 13, fourth controllable electromagnetic valve 14, fifth Controllable electromagnetic valve 15, the sixth controllable electromagnetic valve 16, the seventh controllable electromagnetic valve 17 and the eighth controllable electromagnetic valve 18; the laser working gas in excimer laser 1 is composed of halogen gas F 2 , rare gas Ar, buffer gas Ne and inert gas He four gases, the excimer laser 1 outputs laser pulses, and the monitoring module 2 monitors the pulse energy, spectral li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com