Crystallizing kettle temperature control system and control method

A temperature control method and technology of a temperature control system, which are applied in crystallization regulation/control, solution crystallization, crystallization separation, etc., can solve the problems of slow crystallization speed, small heat transfer rate, and narrow cooling range, and reach the lower limit of increasing cooling. , to ensure smooth progress and reduce the effect of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

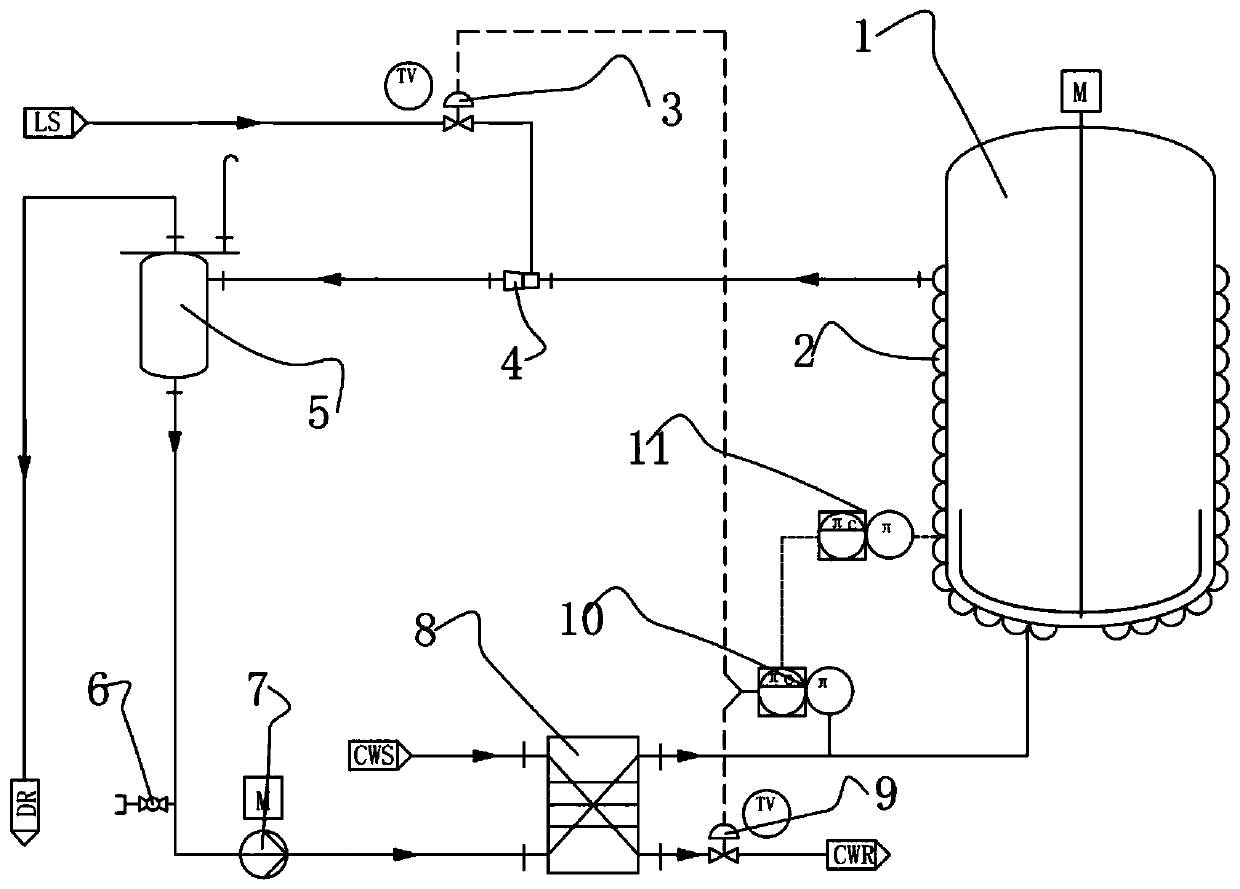

[0042] Such as figure 1 As shown, this embodiment provides a crystallization kettle temperature control system, including:

[0043] A crystallization kettle 1 provided with an outer coil 2 for heating or cooling the crystallization kettle 1 by circulating water passing through it;

[0044] A steam regulating valve 3, which is connected to the steam source through a pipeline, is used to adjust the opening of the steam, and is used to preheat the crystallizer 1 to avoid the formation of crystal scars on the wall of the crystallizer 1 when the material enters, affecting the heat transfer rate and crystallization of the system Product quality and reduce product yield;

[0045] A static mixer 4, the liquid inlet and air inlet of which are respectively connected to the liquid outlet of the outer coil 2 and the exhaust outlet of the steam regulating valve 3 through pipes, and are used to mix the circulating water and steam in the pipeline, Heating the circulating water in the pipeline;

[0...

Embodiment 2

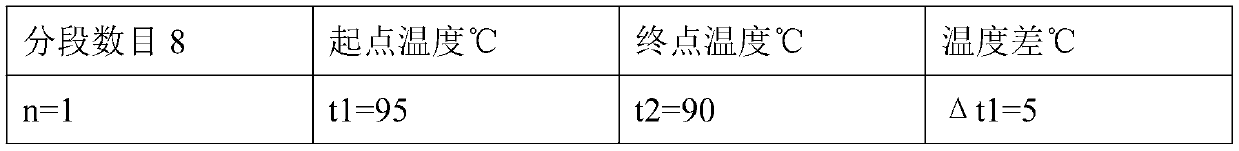

[0053] This embodiment provides a method based on figure 1 The temperature control method of the crystallization kettle of the temperature control system shown specifically includes the following steps:

[0054] Step 1. Inject circulating water from the circulating water injection port 6 and fill the entire heat exchange piping system, and turn on the circulating pump 7;

[0055] Step 2. Set the preheating temperature t1 of the crystallization kettle 1 on the first temperature transmission and temperature display control instrument 10 and the second temperature transmission and temperature display control instrument 11 respectively, and control the steam regulating valve 3 to open, and the steam passes through the static state. The mixer 4 heats the circulating water, and the heated circulating water is sent to the outer coil 2 to preheat the crystallization kettle 1;

[0056] Step 3: When the crystallization kettle 1 reaches the preheating set value t1, the preheating is completed, ...

Embodiment 3

[0067] This embodiment provides an application embodiment based on the above-mentioned temperature control system and control method. The preheating temperature setting value t1=85℃ and the final crystallization temperature setting value tn+1=5℃ is set The temperature range is divided into 3 sections, including the following steps:

[0068] Step 1. Firstly, inject deionized water or living water into the circulation pipeline from the circulating water injection port 6 to fill the entire heat exchange piping system, turn on the circulating water transfer pump 7, and set the first temperature transmission and temperature display control instrument Set the preheating temperature t1 of the crystallization kettle on 10=85℃, and open the steam regulating valve 3;

[0069] Step 2: The steam passes through the static mixer 4 to heat the circulating water, thereby preheating the crystallization kettle 1;

[0070] Step 3. When preheating to 85°C, after preheating is completed, turn on the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| evenness | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com