Filtering concentration device and method for small ternary precursor particles

A concentration device and small particle technology, which is applied in the field of filtration and concentration devices for small particles of ternary precursors, can solve the problem that the feed cannot be too fast, the reaction system cannot have high production efficiency, and the feed volume of the reactor cannot be increased, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

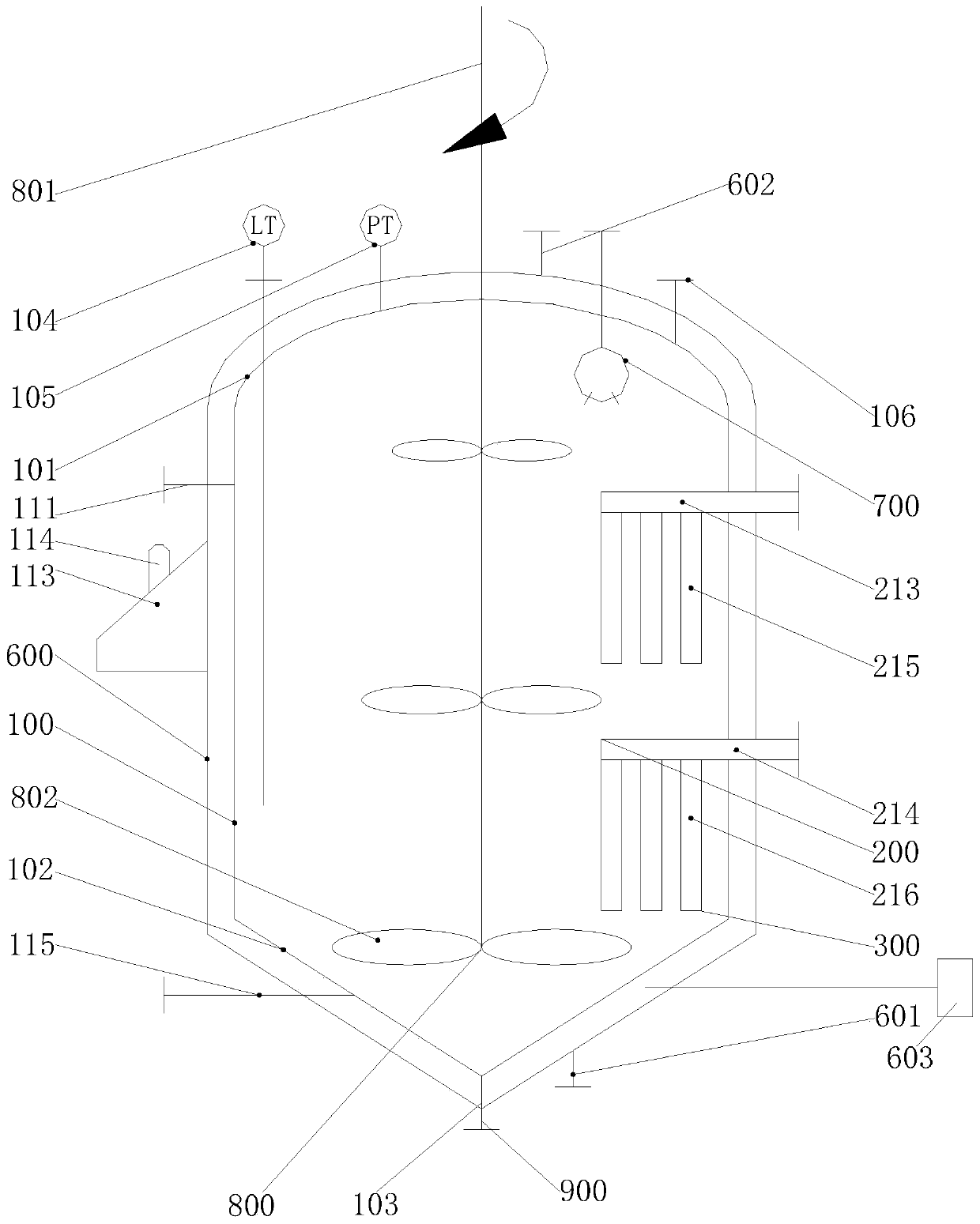

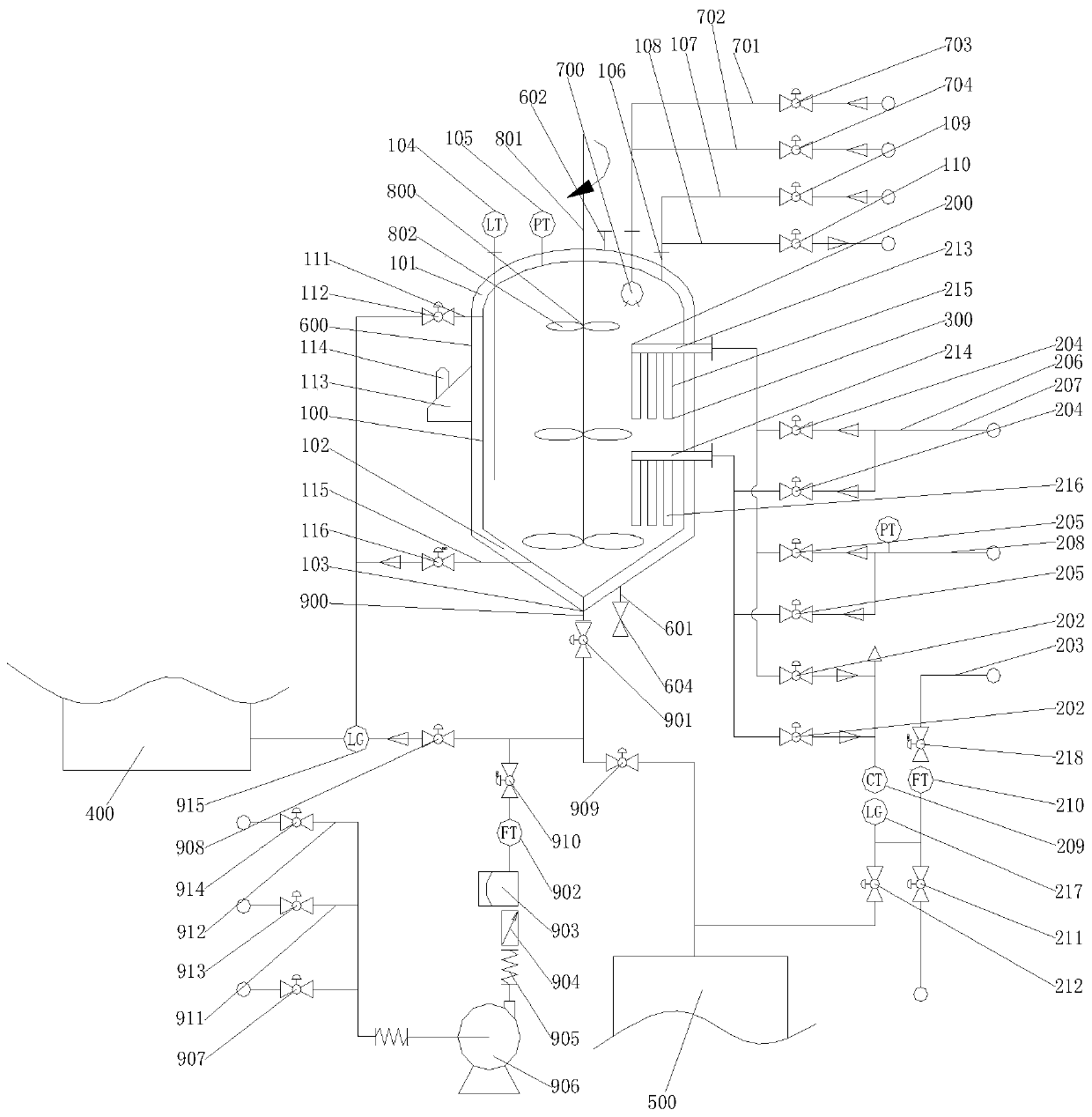

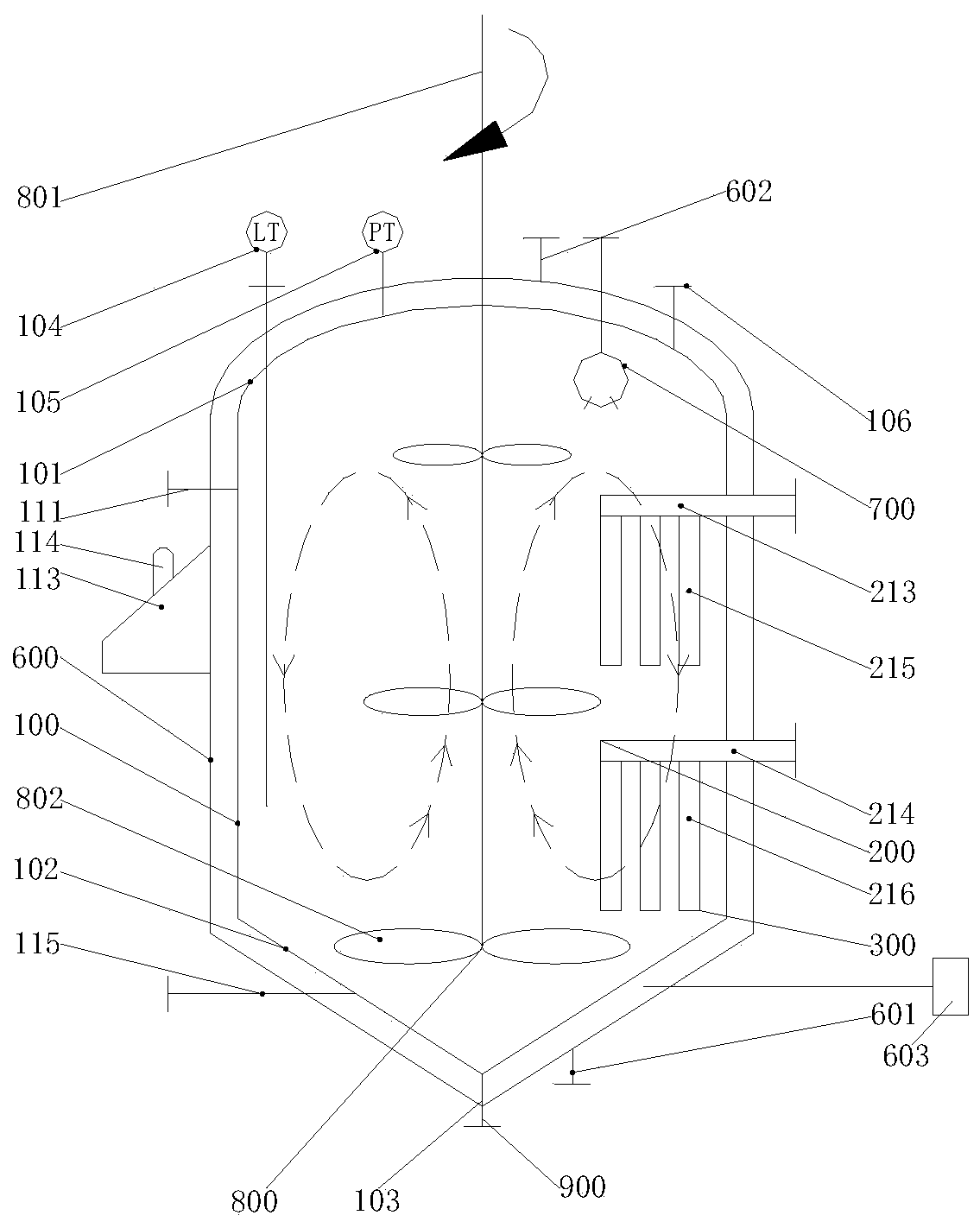

[0085] Such as figure 1 and figure 2 The filtration and concentration device of the small particles of the ternary precursor shown includes such as image 3 As shown in the cylinder 100, one end of the cylinder is provided with a first seal 101, the other end of the cylinder is provided with a second seal 102, and the cylinder or the first seal or the second seal is provided with a feed port 103. One or more groups such as Figure 5 and Figure 6 As shown in the row pipe 200, the row pipe is provided with such as Figure 4 As shown in the microporous filter medium 300, the end of the row pipe communicates with the outside of the cylinder. The row pipe is composed of one or more annular pipes, and several installation holes 201 are arranged on the top or bottom of the annular pipes, and the mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com