Efficient and intelligent reaction crystallization device

A reactive crystallization and intelligent technology, which is applied in crystallization separation, solution crystallization, crystallization adjustment/control, etc., can solve the problems of not being able to observe the crystal shape and particle size in real time, and achieve the effect of good shape, stable product, and guaranteed crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

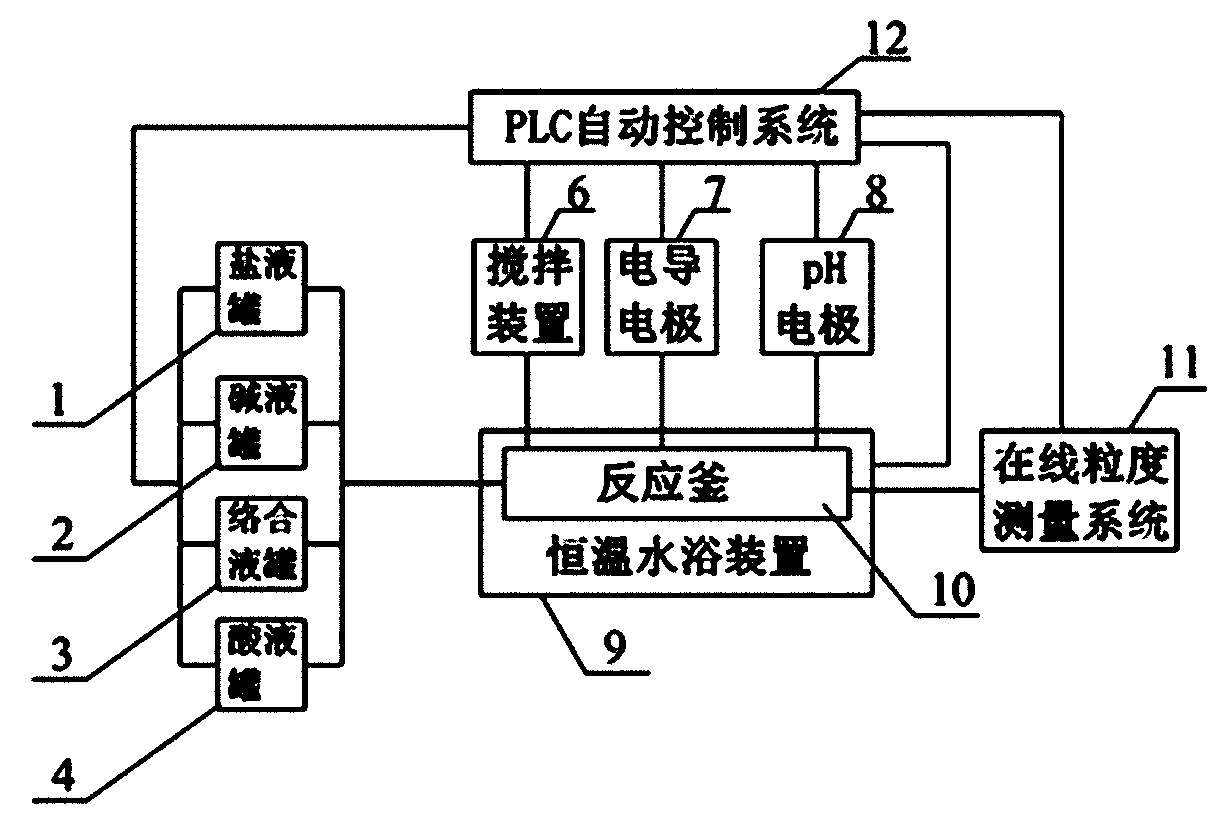

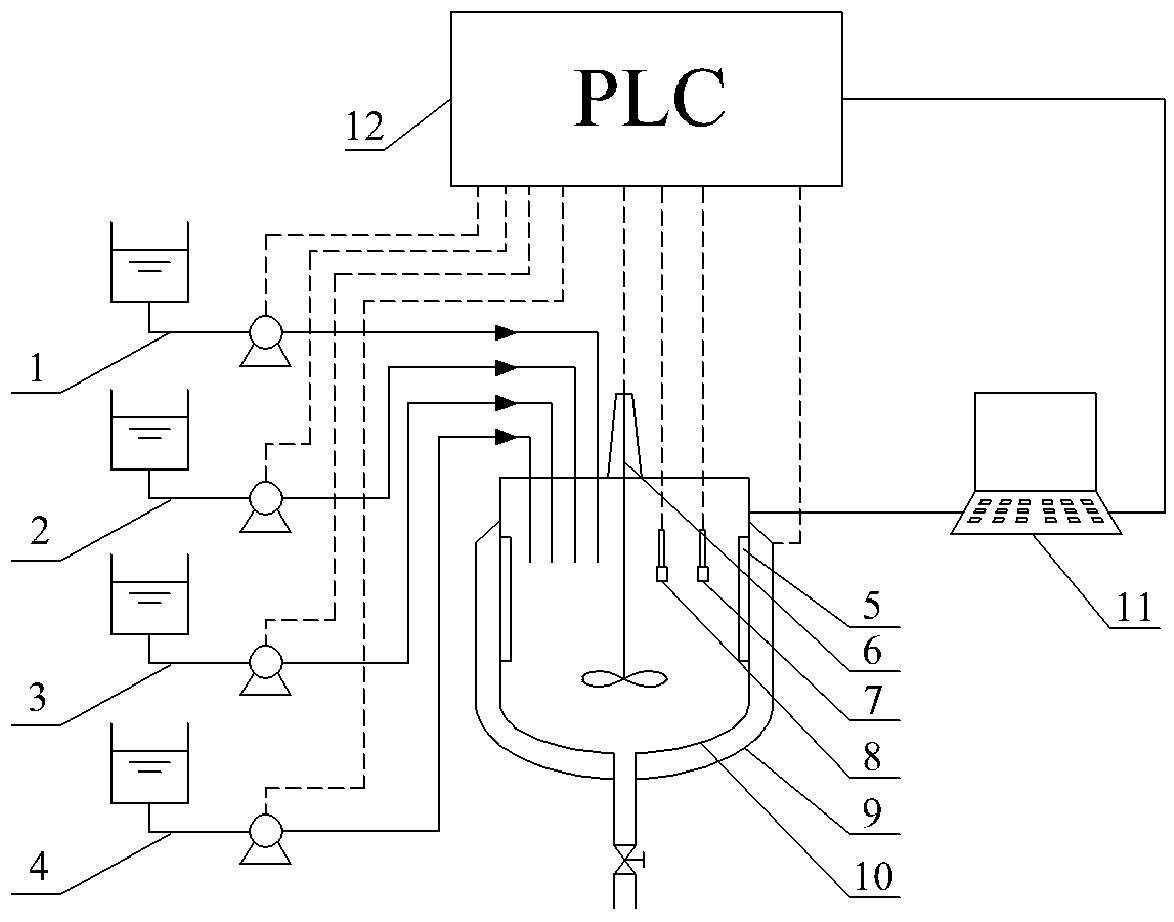

[0034] Add the reaction bottom solution in the 10 L reactor, including 9.5 L of pure water, a total of 623 g of nickel sulfate, cobalt sulfate and manganese sulfate solids weighed in a molar ratio of 6:2:2, 0.3 L of ammonia water and 192 g of hydrogen Sodium oxide solid, etc. Prepare a mixed salt solution of nickel sulfate, cobalt sulfate and manganese sulfate with a concentration of 0.8 mol / L at a molar ratio of 6:2:2 and add it to the salt solution tank 1, and add 1.4 mol / L sodium hydroxide solution to the lye tank 2, 1 mol / L ammonia solution is added to the complexing liquid tank 3, and the prepared sulfuric acid solution with a concentration of 1 mol / L is added to the acid liquid tank 4. The inner wall of the reaction kettle 10 is provided with baffles 5, four of which are arranged along the circumferential direction, so as to reduce the directional flow of the liquid and enhance the turbulence. The PLC automatic control system 12 is the automatic control center of the wh...

Embodiment 2

[0036] at 2 m 3Add the reaction bottom liquid in the reaction kettle, including 1940 L pure water, nickel sulfate, cobalt sulfate and manganese sulfate solids weighed in a molar ratio of 8:1:1, a total of 124.6 kg, 60 L ammonia water and 38.4 kg sodium hydroxide solid Wait. Prepare a mixed salt solution of nickel sulfate, cobalt sulfate and manganese sulfate with a concentration of 0.8 mol / L at a molar ratio of 8:1:1 and add it to the salt solution tank 1, and add 1.4 mol / L sodium hydroxide solution to the lye tank 2, 1 mol / L ammonia solution is added to the complexing liquid tank 3, and the prepared sulfuric acid solution with a concentration of 1 mol / L is added to the acid liquid tank 4. The inner wall of the reaction kettle 10 is provided with baffles 5, eight of which are arranged along the circumferential direction, so as to reduce the directional flow of the liquid and enhance the turbulence. The PLC automatic control system 12 is the automatic control center of the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com