Ball-milling oxidation-sulfhydrylation modified biochar, and preparation method and application thereof

A technology of oxidation modification and biochar, applied in the direction of chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of easy generation of biochar solid dust and low efficiency of ball milling, and achieve economical and easy equipment and preparation process Realize and improve the efficiency of ball milling and simplify the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

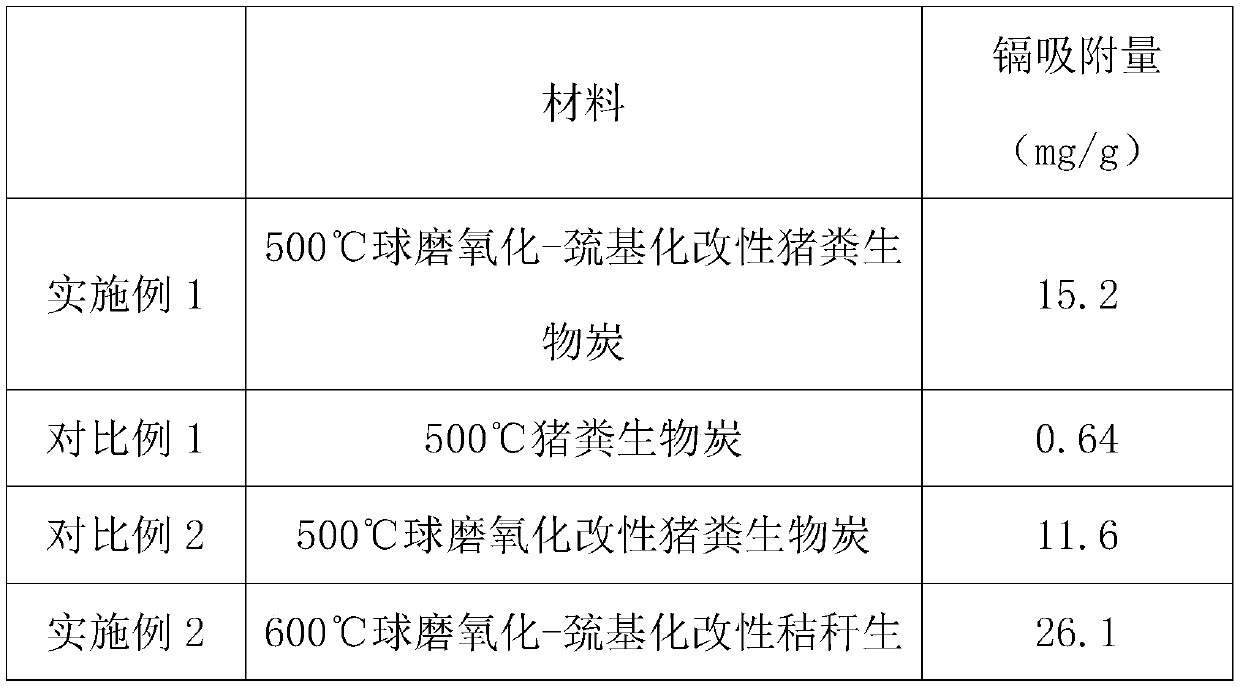

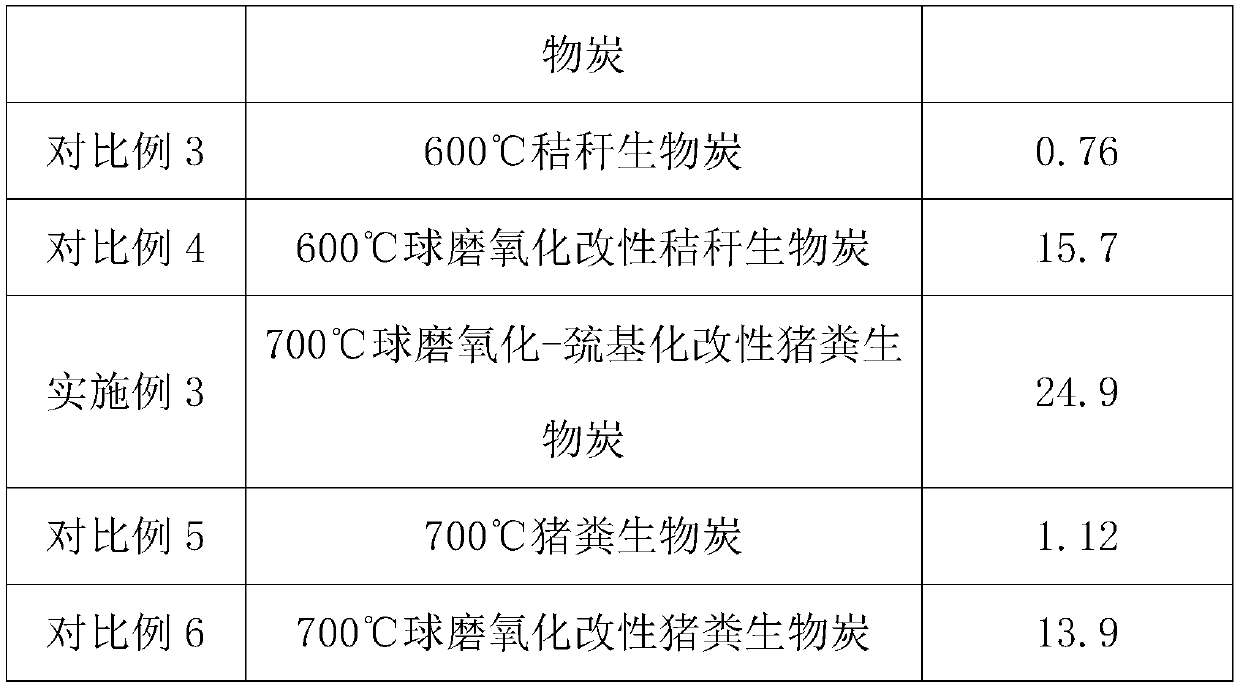

Embodiment 1

[0035] (1) Collect dried animal manure and put it into the furnace. In this example, pig manure is used. Under anaerobic or anaerobic conditions, nitrogen can generally be used. First, the temperature is raised to the preset temperature at a rate of 2.5°C / min. , and pyrolysis and carbonization at a temperature of 500°C for 10 hours, and take it out after the temperature in the furnace is naturally cooled to room temperature;

[0036] (2) Take 3.0g of biochar prepared in step (1), put it in a ball mill tank, add 45g of hydrogen peroxide and 45g of water, and then add 200g of agate beads (agate beads are supporting equipment for the ball mill), and use a ball mill to grind the biochar to a particle size of Micro-nano level, preferably 0.1-10 microns, generally use a ball mill to mill at a speed of 100-250 rpm for 1-10 hours, in this embodiment, the speed is 250 rpm, ball mill for 3 hours, and collect the solid by suction filtration after ball milling Biochar modified by ball mil...

Embodiment 2

[0043] (1) Collect the dried stalks and put them into the furnace, heat up to the preset temperature at a rate of 5°C / min in a nitrogen atmosphere, and then pyrolyze and carbonize it at 600°C for 5 hours, and wait for the temperature in the furnace to cool naturally Take out after reaching room temperature;

[0044] (2) Take 3.0g of biochar prepared in step (1), put it in a ball mill tank, add 50g of hydrogen peroxide and 50g of water, and then add 200g of agate beads, and use a ball mill to grind the biochar to a micro-nano particle size, preferably to 0.1- 10 microns, generally use a ball mill to mill for 1-10 hours at a speed of 100-250 rpm, in this embodiment, the speed of rotation is 250 rpm, and the ball mill is 3 hours, after the ball milling, the solid biochar after ball milling oxidation modification is collected by suction filtration ;

[0045] (3) Take 1.0 g of the ball-milled oxidation-modified biochar prepared in step (2), put 50 g of 2% ethanol solution containi...

Embodiment 3

[0051] (1) Collect the dried animal feces and put them into the furnace. Under the nitrogen atmosphere, the temperature is first raised to the preset temperature at a rate of 10°C / min, and then pyrolyzed and carbonized at 700°C for 1 hour, and the temperature in the furnace is naturally Take out after cooling to room temperature;

[0052] (2) Take 3.0g of biochar prepared in step (1), put it in a ball mill tank, add 80g of hydrogen peroxide and 80g of water, and then add 200g of agate beads, and use a ball mill to grind the biochar to a micro-nanometer particle size, preferably to 0.1- 10 microns, generally use a ball mill to mill at a speed of 100-250 rpm for 1-10 hours, in this embodiment, the speed of rotation is 250 rpm, and the ball mill is for 5 hours. After the ball milling, the solid biochar after ball milling oxidation modification is collected by suction filtration ;

[0053] (3) Take 1.0 g of the ball-milled oxidation-modified biochar prepared in step (2), put 50 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com