A kind of repairing agent and its preparation method and application

A restorative agent and heavy metal technology, applied in the field of soil remediation, can solve the problems of cadmium and arsenic antagonistic effect defects, etc., and achieve the effects of improved curing effect, short repair period and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

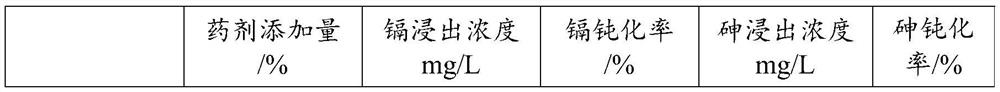

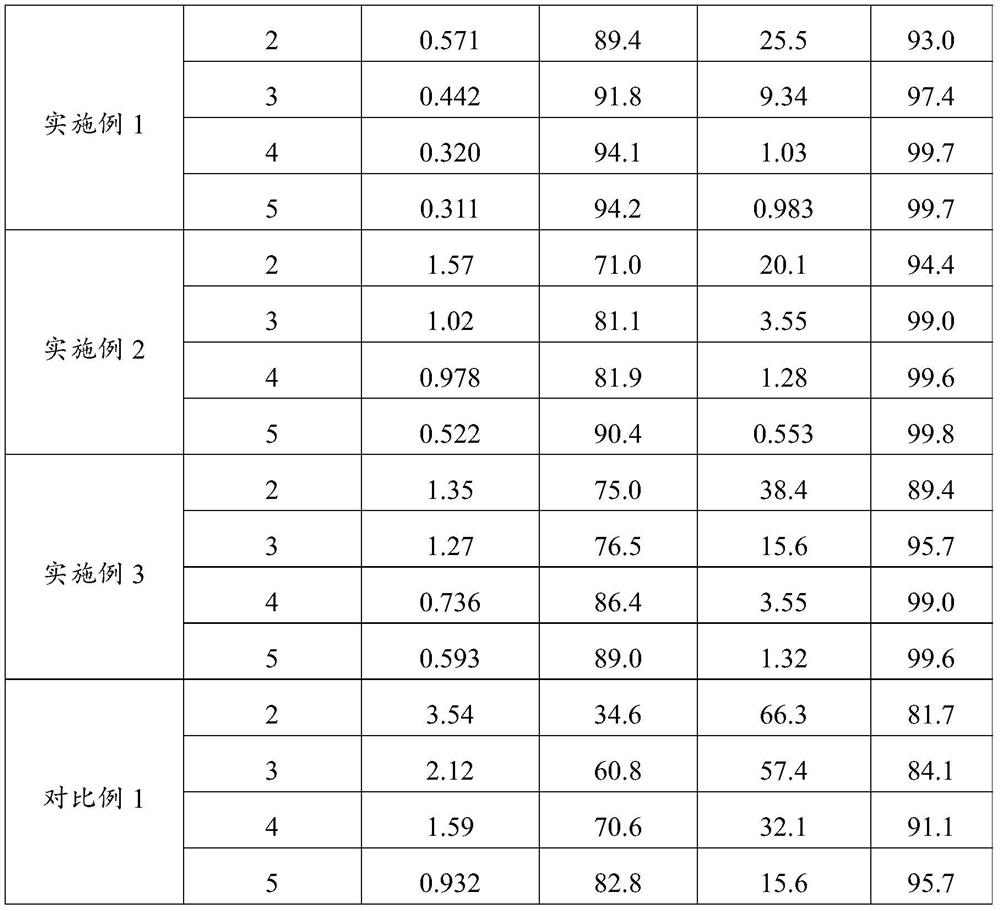

Examples

Embodiment 1

[0030] The present embodiment provides a kind of repairing agent, and its preparation method is as follows:

[0031] Preparation of Biochar:

[0032] The corn stalks were ground and passed through a 2 mm sieve, and the undersize was baked at 105 °C for 1 h and then continued to be roasted in a muffle furnace at a heating rate of 10 °C / min to 600 °C for 2 hours to obtain biomass charcoal.

[0033] Preparation of Restorative:

[0034] Weigh 500g of the above-mentioned biomass charcoal, 300g of tailings, 200g of dolomite, 200g of agate beads, and 100mL of water, then put them in a ball-milling jar, and mill them at 500rpm for 5min. The material is ground and passed through a 2mm sieve, and the material under the sieve is the repair agent.

Embodiment 2

[0036] The present embodiment provides a kind of repairing agent, and its preparation method is as follows:

[0037] Preparation of Biochar:

[0038] The rice husks were ground and passed through a 2 mm sieve, and the undersize was baked at 105 °C for 1 h and then continued to be roasted in a muffle furnace at a heating rate of 10 °C / min to 600 °C for 2 hours to obtain biomass charcoal.

[0039] Preparation of Restorative:

[0040] Weigh 400g of the above-mentioned biomass charcoal, 370g of tailing iron ore, 150g of dolomite, 240g of agate beads, and 100mL of water, put them in a ball-milling jar, and perform ball milling at 500rpm for 5min. The material is ground and passed through a 2mm sieve, and the material under the sieve is the repair agent.

Embodiment 3

[0042] The present embodiment provides a kind of repairing agent, and its preparation method is as follows:

[0043] Preparation of Biochar:

[0044] The corn stalks were ground and passed through a 2 mm sieve, and the undersize was baked at 105 °C for 1 h and then continued to be roasted in a muffle furnace at a heating rate of 10 °C / min to 600 °C for 2 hours to obtain biomass charcoal.

[0045] Preparation of Restorative:

[0046] Weigh 600g of the above-mentioned biomass charcoal, 230g of iron ore tailings, 250g of dolomite, 300g of agate beads, and 110mL of water, put them in a ball-milling jar, and mill them at 500 rpm for 5 minutes. The material is ground and passed through a 2mm sieve, and the material under the sieve is the repair agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com